When we set out to develop a new way of building mountain bikes at Apogee Bikes, I knew we were embarking on an ambitious journey of design and development. For that reason, I want to cover why we chose to use Onshape, PTC’s cloud-native CAD platform, and how it has helped us bring our innovative modular bike to market in record time.

Apogee One: The First of Its Kind

(Courtesy Images: Apogee Bikes)

(Courtesy Images: Apogee Bikes) Our story begins in January 2023 when I collaborated with Collin Huston of Huston Precision to reimagine mountain bike construction in the United States. We developed what we now call the Free-Float Module (FFM), a standalone suspension module that supports a frame. By August 2023, we had built our first prototype and brought on three more founding partners to launch Apogee.

Just one year later in 2024, we introduced the Apogee One, a 140mm travel trail bike designed to deliver unparalleled ride quality and the first bike built on the FFM platform.

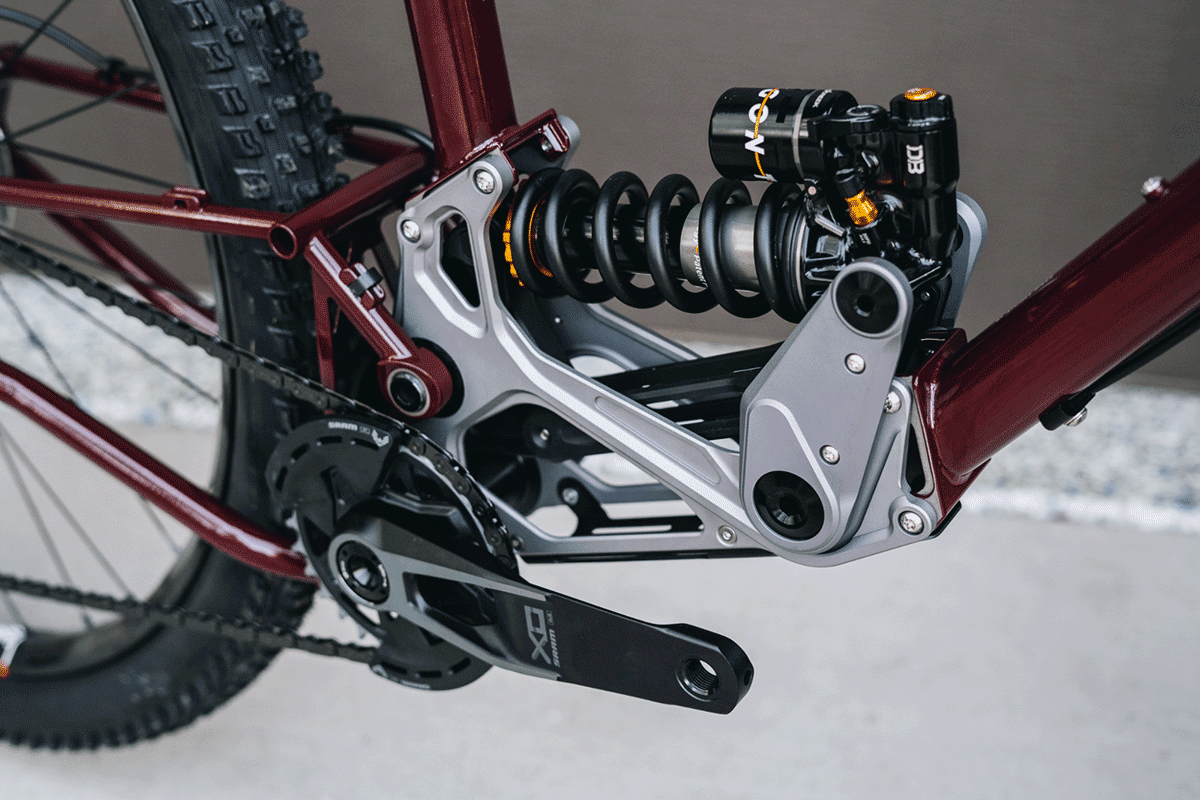

Precision-machined Free-Float Module at the heart of the Apogee One.

Precision-machined Free-Float Module at the heart of the Apogee One.  The Apogee One: As comfortable in the air as it is on the ground.

The Apogee One: As comfortable in the air as it is on the ground. The frame design is decoupled from the suspension to achieve the best of both: a refined frame that carves and rides smoothly, plus a compact suspension system that keeps the center of gravity low and with a ride as smooth as you can get without paving the trail.

Onshape in Action: 5 Game-Changing Features

It is no small feat to build a company, build a proof of concept, and turn it into a production-ready bike all within a year.

One sideplate of the Free-Float Module mid-production.

One sideplate of the Free-Float Module mid-production. To pull off this mammoth task, we needed a CAD system that could scale and allow manufacturing teams to work hand-in-hand with the design team to cut down on development time. We required a platform that would:

-

Enable rapid design iterations

-

Provide robust analysis capabilities

-

Allow easy management of product releases as our modular platform grew

-

Facilitate collaboration between our design and manufacturing teams

Onshape ticked all these boxes and more. Let’s take a look at how this platform shaped our development process.

1. Parallel Design Work

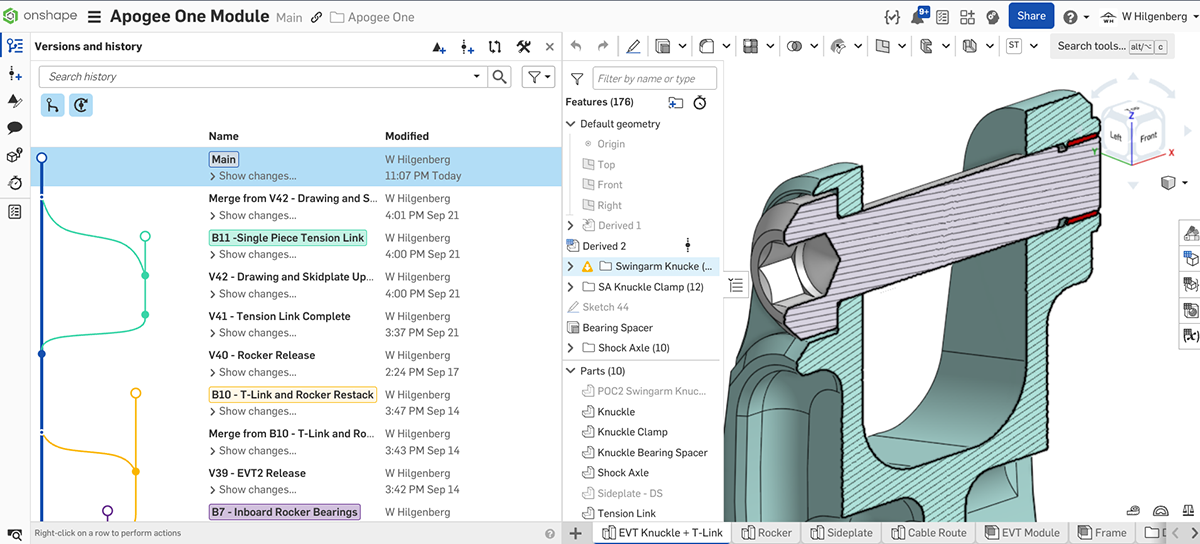

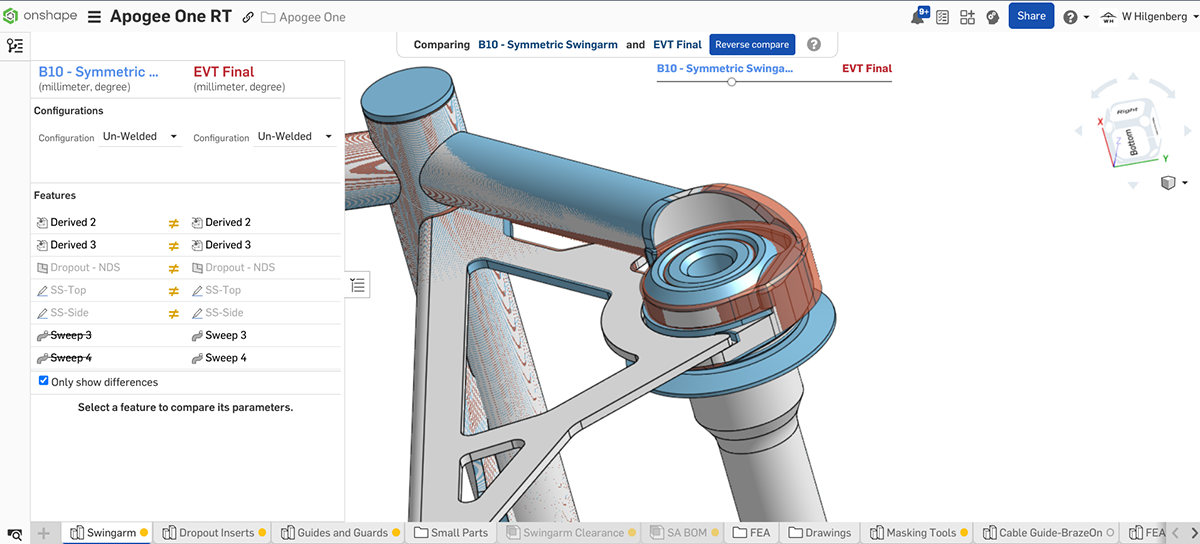

The modularity of our FFM requires us to confirm that design changes in one iteration are compatible with the existing architecture. Onshape’s in-process design tree and part compare features allow us to explore design iterations while compatibility with parts that have already been produced.

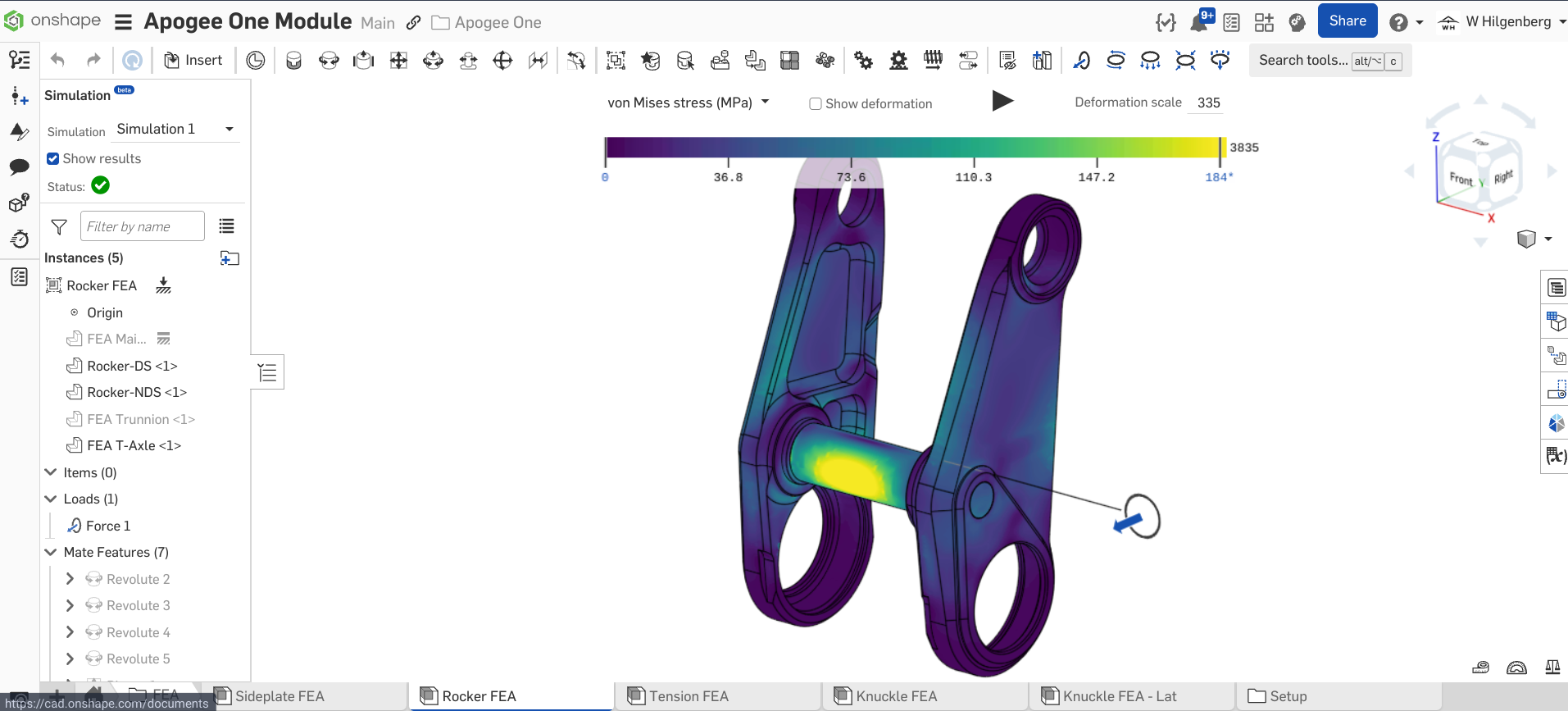

2. Rapid Structural Analysis

Onshape’s integrated cloud-computed structural analysis package proves to be an invaluable asset to our development. Onshape Simulation provides quick, directional answers that save time in every design-build-test cycle.

3. Real-Time Collaboration

One of our key strategies for U.S. manufacturing is close collaboration between our design and manufacturing teams. Onshape’s online platform gives our manufacturing engineers earlier access to native CAD, allowing them to provide crucial DFM and DFA feedback. This results in prototypes that are much closer to production-ready components at the first drawing release.

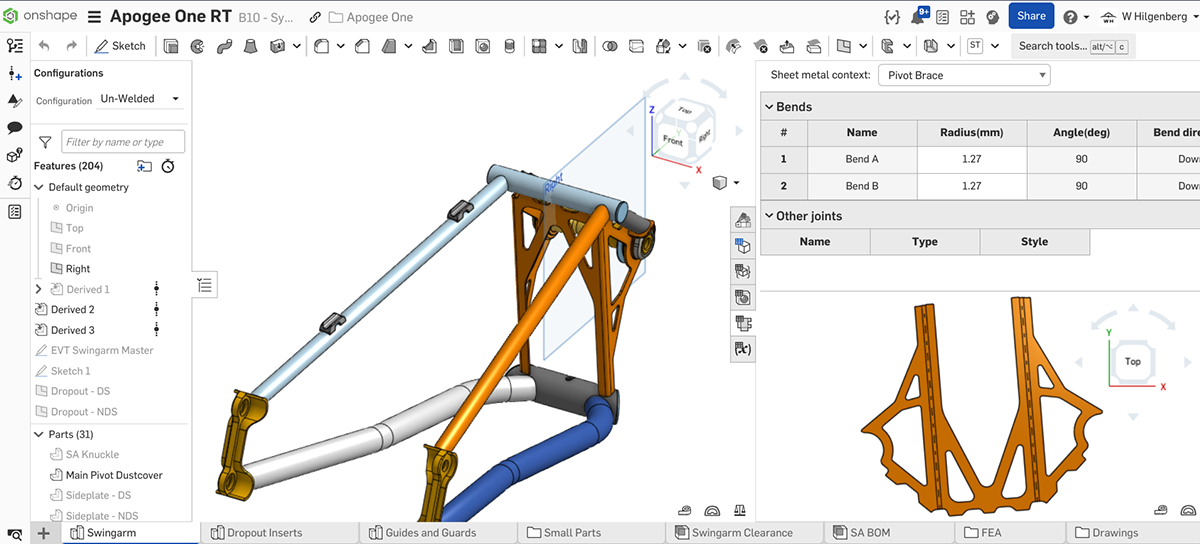

4. Multi-Material Design

Our DuoFrame concept involves two very different manufacturing methods: machining and weldments. Onshape’s integrated sheet metal capability allows us to design all aspects in a single Part Studio, streamlining our process significantly.

5. Rolling Release Structure

By combining Onshape’s analysis and design functionality with a robust PDM setup, we implemented a rolling release structure. This approach has helped us reduce time to production by as much as 40 percent compared to traditional batch-release methods.

Solutions That Last

An Apogee One prototype in its natural environment

An Apogee One prototype in its natural environment As we look ahead to expanding our product line, we’re confident that Onshape will continue to be the right solution for us. Its scalability, built-in PDM, and easy connection to Onshape’s Release Management ensure that we’re well-prepared to meet future engineering challenges.

Our experience at Apogee Bikes demonstrates the transformative power of choosing the right CAD system from the outset. For those of you who are also looking to develop new hardware products in a competitive market, I can’t stress enough how important this decision is. A powerful, flexible, and collaborative CAD platform like Onshape can be the difference between leading the pack and playing catch-up.

The Onshape

Discovery Program

Learn how qualified CAD professionals

can get Onshape Professional

for up to 6 months – at no cost!