At PTC, innovation isn’t just something we talk about – it’s something we live and breathe.

That’s why every year the Onshape team participates in an annual design competition. It’s a chance for us to roll up our sleeves, dive into the software, and push the boundaries of what’s possible with cloud-native CAD.

This year’s entries didn’t just impress; they blew us away. From intricate mechanical assemblies to clever coding solutions, our team showcased the incredible versatility and power of Onshape. While this friendly competition helps us stay connected with the user experience, it’s also about celebrating creativity and innovation.

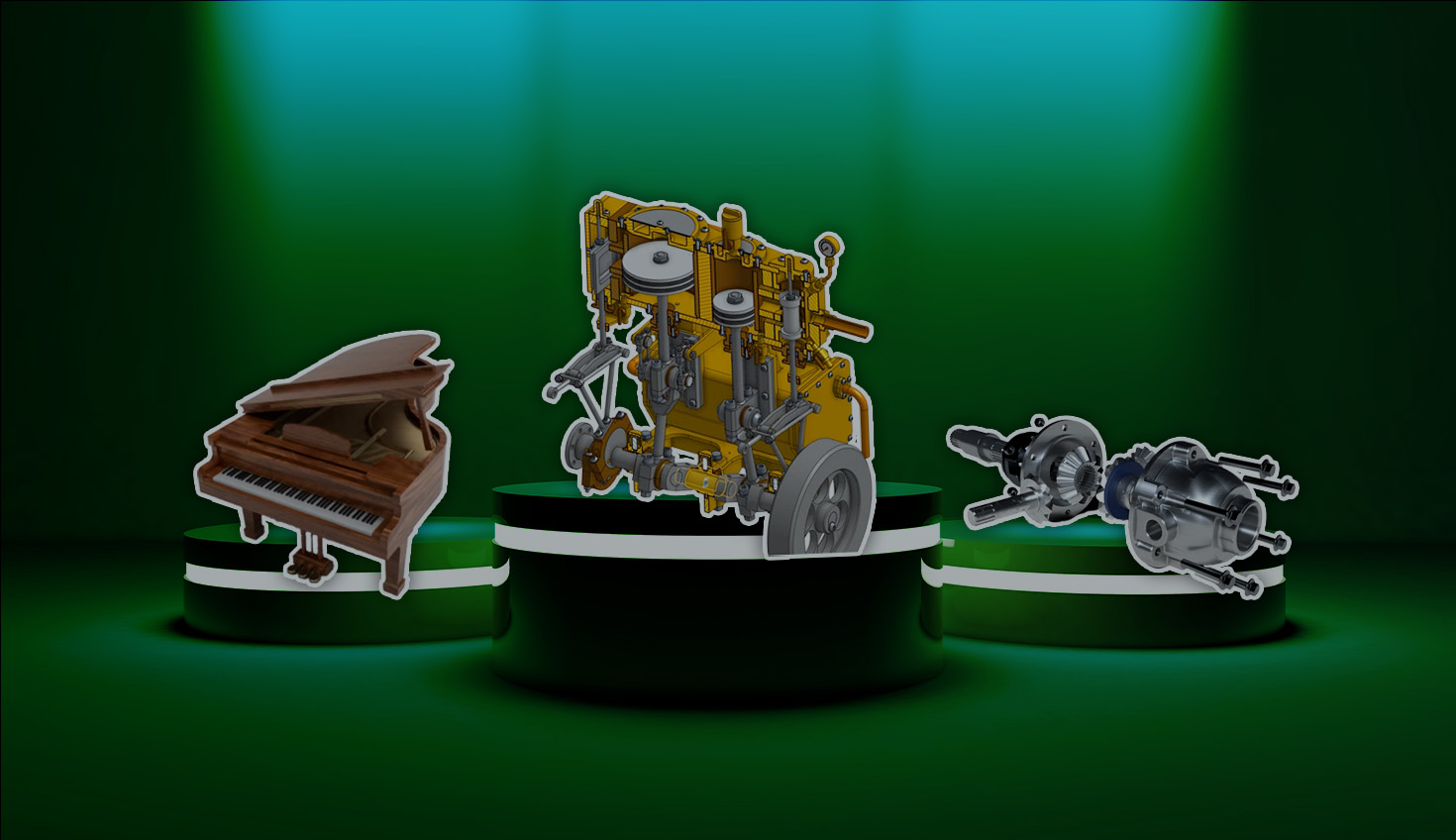

This year, there were three categories: Design It, Hack It, and Meme It.

So, grab a coffee and settle in as we take you on a tour of the most impressive entries from this year’s Onshape internal design throwdown!

‘Design It’: Part & Assembly Modeling

CoreXY Printer

This CoreXY 3D printer design – a work in progress by Principal Software Engineer Anton Bovin – showcases the power of Onshape in handling complex, moving assemblies. This printer uses a clever belt arrangement to reduce moving mass, potentially leading to faster and more precise prints. Anton modeled the entire printer, including the kinematic bed that can self-level using three independently controlled motors. While still a work in progress, this project demonstrates how Onshape can be used to prototype and iterate on cutting-edge mechanical designs.

Differential Gearbox

This meticulously modeled differential gearbox is a testament to Onshape's precision in gear modeling. Getting the gears to mesh perfectly was a significant challenge, pushing the limits of Onshape's constraint and mate capabilities. Engineering Product Development Leader Nacho Martos used Onshape's powerful visualization tools to create stunning exploded views and photorealistic renderings, bringing this complex mechanical assembly to life.

Self-Centering Dowel Jig

For his second entry, Nacho’s self-centering dowel jig is a cleverly designed woodworking essential features a mechanism where each clamping screw has threads that spiral in opposite directions, allowing the jig to center itself on the workpiece and ensure perfectly aligned holes. Nacho utilized Onshape's Variable Studios to model different bushing configurations, giving users the flexibility to accommodate a range of hole sizes. The single-curve thread design, which branches off into two opposing spiral paths, eliminates the need for separate threaded components, streamlining the assembly and ensuring smooth, reliable operation.

Compound Condensing Steam Engine

Jeremy Regnerus’ steam engine model is a masterclass in historical recreation using modern CAD tools. This intricate design features multiple cylinders, valves, and a camshaft system, all working in harmony. Jeremy, Senior Principal Solutions Engineer, utilized Onshape’s multi-part modeling capabilities to create every component with exacting detail. The project showcases how Onshape can handle assemblies with hundreds of parts, making it ideal for both modern and historical mechanical design work.

Jeremy took home the Judges’ & People’s Choice awards.

1997 GMC Suburban Center Console

Mark Cheli's center console upgrade for his vintage SUV is a perfect example of using CAD software to solve real-world problems. He designed a custom mount for a wireless CarPlay screen, integrated cup holders (which were surprisingly absent in the original design), and even added a spring-loaded compartment for his wallet. Mark, who is the Director of R&D Strategy, leveraged Onshape’s in-context design capabilities to ensure his creation fit perfectly within the existing vehicle interior. This project highlights how Onshape can be used for practical, everyday design challenges.

Mountain BFF

David Nguyen’s rock climbing cam (dubbed "Mountain BFF") is a crucial piece of safety equipment brought to life in Onshape. The model showcases different configurations of the cam, demonstrating how it expands and contracts to fit various crack sizes. David – a senior technical service engineer – even used Onshape's simulation capabilities to analyze the cam's performance under different loads. The project was complemented by high-quality renderings, showcasing Onshape's integration with rendering tools.

Intern Submissions

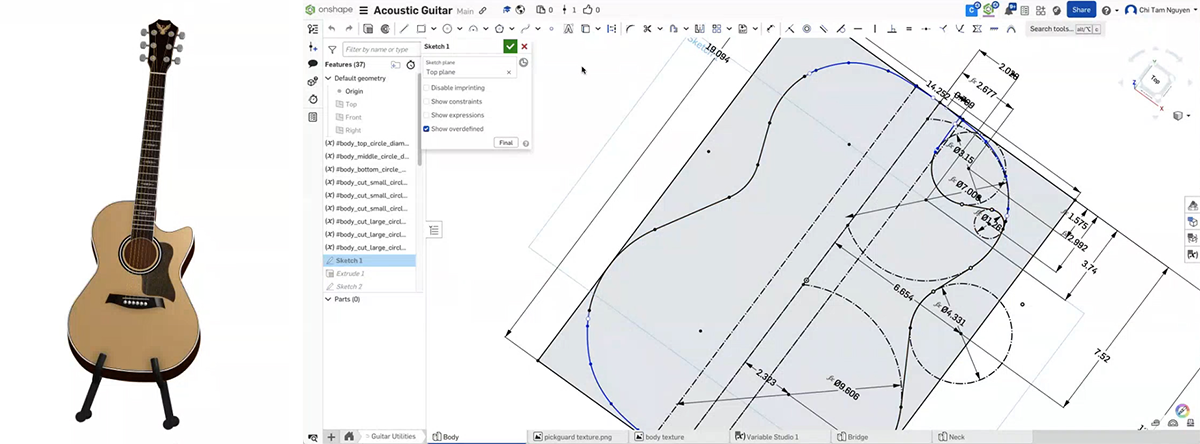

Acoustic Guitar

Interns Chi Tam Nguyen and Dan Vu’s acoustic guitar model is a symphony of detail. From the intricate fretboard inlays to the precisely modeled bridge and tuning pegs, no element was overlooked. The team used Onshape’s multi-part modeling to create each component separately and then brought them together in a complex assembly. They even modeled the tension in the strings, showcasing Onshape's ability to represent subtle design elements.

Piano

Intern Luciano Nargang’s grand piano model is a tour de force of complex assembly management in Onshape. With hundreds of individual parts, including a fully functional key action mechanism, this project pushed the limits of what’s possible in cloud-native CAD. Luciano used Onshape’s robust assembly tools to manage this intricate hierarchy of components, demonstrating how the platform can handle even the most complex musical instruments.

Luciano won the Intern Award.

‘Hack It’: FeatureScript & Custom Features

In addition to the impressive mechanical and assembly designs, our team also showcased their

technical prowess with a variety of FeatureScript-ed custom features. Anton developed tools for generating QR codes and creating geodesic polyhedrons, while Software Engineer Erik Christensen brought FeatureScript development into the Visual Studio Code environment. (Erik took home the People’s Choice Award.).

Anton’s QR code custom feature.

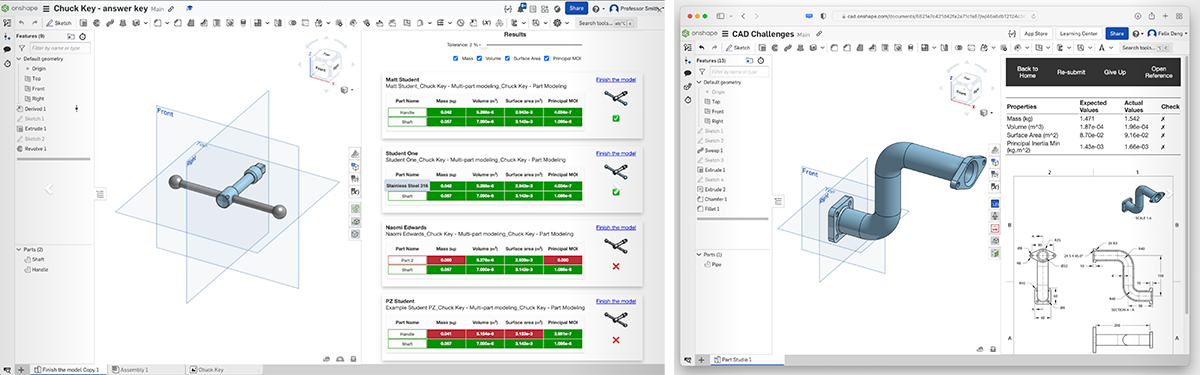

Education Team’s Matt Mueller and Matt Shield paired up to develop two new Onshape for Education capabilities: CAD Checker and CAD Challenges. The CAD Checker took home the Judge’s Choice award for the “Hack It” category.

The Matt’s CAD Checker, right, and CAD Challenges interface.

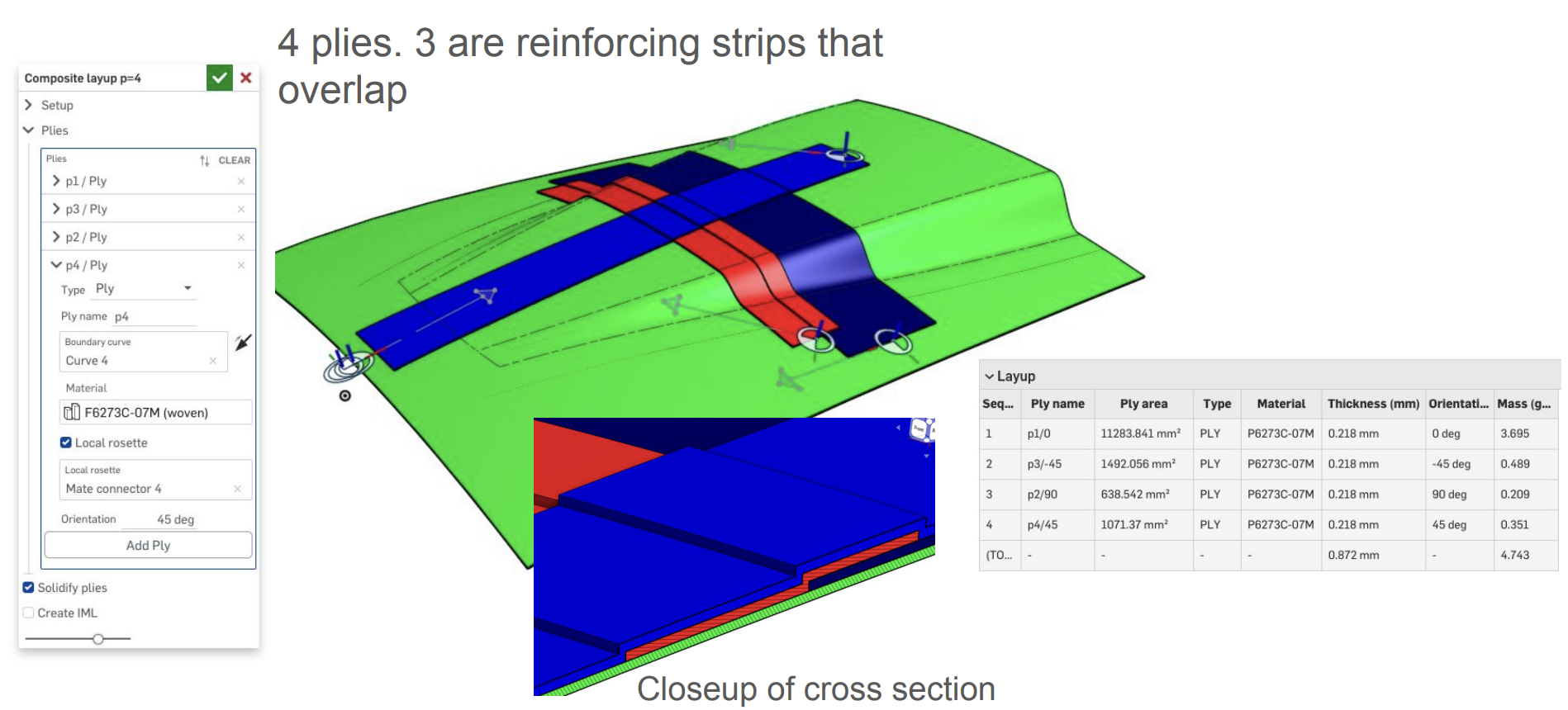

The Matt’s CAD Checker, right, and CAD Challenges interface. Head of Product Greg Brown’s composite modeling tools bring advanced aerospace design techniques into Onshape. The feature allows users to define and visualize complex material layups, complete with ply orientations and properties. It even generates detailed ply books, essential for manufacturing composite parts. This project demonstrates how FeatureScript can be used to add industry-specific functionality to Onshape.

Greg’s composite modeling tools.

Greg’s composite modeling tools. ‘Meme It’: Putting the Fun in Functional

While the design competition was all about showcasing technical creativity, we couldn’t resist a light-hearted series of fun, relatable memes. The team captured the struggles and triumphs of transitioning to Onshape, from convincing traditional CAD users to make the switch to reveling in the discovery of Onshape's powerful features. These memes not only highlight our team’s wit but also provide a lighthearted look at the Onshape user experience.

Create Your Best CAD Design

As the digital dust settles on this year's competition, we're left in awe of the sheer ingenuity on display. These entries aren't just cool designs – they're a testament to the power of cloud-native CAD and the incredible community that pushes it to new heights every day.

Our annual design throwdown serves as a reminder of why we do what we do. It's not just about building software; it's about empowering creators, problem-solvers, and innovators to bring their ideas to life. Whether you're designing the next breakthrough product or tackling a DIY project at home, Onshape is here to turn your vision into reality.

The Onshape

Discovery Program

Learn how qualified CAD professionals

can get Onshape Professional

for up to 6 months – at no cost!