We’re inundated with beauty standards – just hop on Instagram to find filtered faces and perfectly styled homes (why is it all beige?). It’s inescapable.

For everyday consumer products, it’s much the same (thanks Apple). A curved edge or the correct material finish can make all the difference in the world for the success of a product.

This makes the look of a product ever more important. After all, we live in a visual world and no one wants an ugly product – a fact industrial designers are well-acquainted with.

What’s Industrial Design?

Industrial design is the balance between beauty and functionality and lives where manufacturing and art intersect.

Industrial designers not only have to worry about a product’s aesthetic but its manufacturability, the costs associated with using certain materials, its durability, and how the product fits together with its internal elements. They have to consider brand guidelines as well as the needs of the consumer, who demands products that are eco-friendly, long-lasting, sustainable, and more (so much more!). On top of everything else, they have to be able to communicate their ideas throughout the entire process.

What Industrial Designers Do to Make Beautiful Products

Ever shopped for a toaster and elected to buy the one that’s red and shiny even if there’s nothing different about its functionality? Thank an industrial designer for that, or rather, a team with the skills to bring the product to life.

With an eye for aesthetics, a full understanding of the consumer mentality, and engineering know-how, industry designer teams are experts on stuff, things, and everything in between.

Get a full understanding of industrial design by watching this video featured on the Industrial Designers Society of America (IDSA) website.

Since every industrial designer has to consider the appearance, functionality, and manufacturability of a product, they are one part storyteller, one part artist, and two parts engineer, leading to a wide range of skills.

According to the IDSA, there are several common skills most designers need to hone in on, but one, in particular, can lead to success: 3D modeling using computer-aided design (CAD) software.

Need-to-Know Skills in Industrial CAD Design

If you know how to use CAD, you’ll be able to perform the gamut of tasks needed to become a professional industrial CAD designer. Here’s how:

Drawing, Sketching, & 3D Modeling

To accurately depict a product before it’s even made, designers draw it out. Many use pen and paper, or a drawing app on an iPad at first. Either way, this is an important skill to build in order to accurately design a product and share it with others in the product development process.

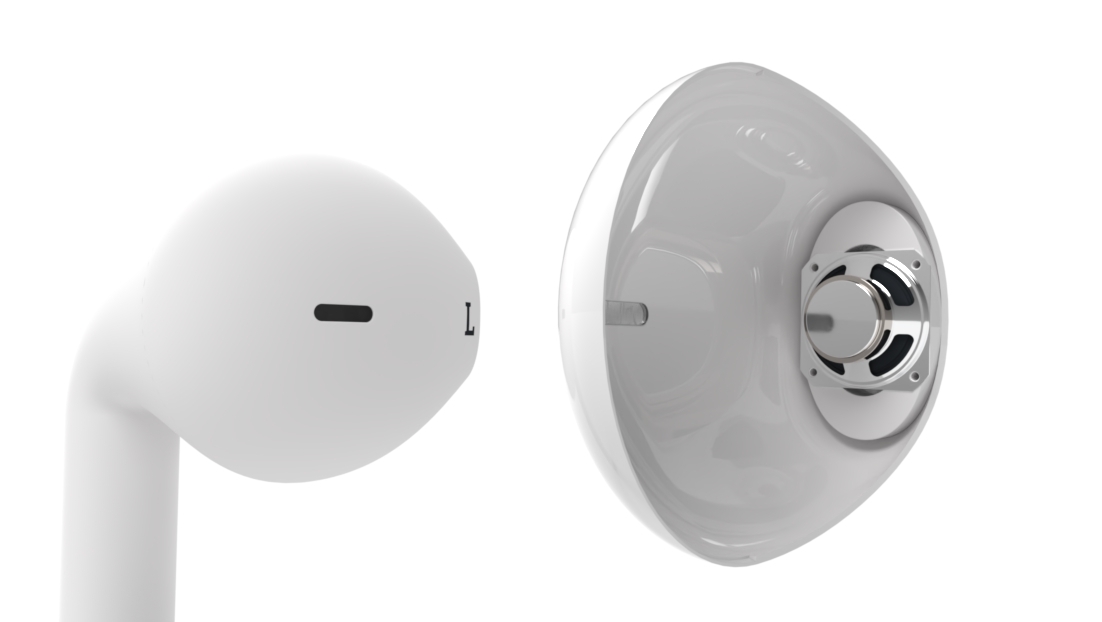

Then, by taking a drawing or sketch to a 3D modeling software system, designers will be able to visualize exactly how the product will look, and make changes before the design is set in stone – saving time and money.

CAD tools, like Onshape, allow industrial CAD designers to build off original drawings and sketches by importing images straight into the software. By using surfacing tools built into CAD, designers can trim, sculpt, and define the perfect product.

3D Rendering & AR View

CAD can also make 3D rendering an easier experience for downstream visualization. Building renders with the correct lighting and settings can help better communicate ideas with clients and other stakeholders.

Related to accurate photorealistic renderings, is the use of materials. Industrial designers must understand how colors, finishes, and materials play into marketing and manufacturing a product. Rendering can help establish whether red will perform better than blue, or whether a matte finish will look better under certain lighting conditions.

In addition to renderings, CAD tools like AR View can assist industrial designers to see their products in a real-life environment at any point in the 3D modeling process – and all on a mobile device.

Simulation

Material choices go beyond looks and affect the durability of the product and the technical limitations of the product. If metal is used instead of plastic, it'll last longer but can affect pricing.

Simulation tools that work smoothly with CAD software can help test the 3D model, and inform any pre-manufacturing decisions. Industrial designers with easy access to linear static analysis can quickly iterate on form vs. function to get the right balance between the right look and engineering requirements related to weight and load capacity.

With built-in simulation, designers can share the drawings, renderings, and simulation results to align with the entire team and ensure accurate results.

Communication Throughout the Process

Most of all, industrial designers need to have communication skills and the tools to easily share information with their own team, stakeholders, clients, and the manufacturing floor.

By leveraging collaboration tools offered by CAD, working in parallel with colleagues from the get-go is possible, leading to a quicker time-to-market, prettier products, and happier customers.

Transparent CAD workflows quicken the feedback loop and further evolve the product with each iteration.

A Powerful CAD Software for Industrial Designers

Onshape is the most powerful tool an industrial designer can utilize that includes built-in data management, rendering, and simulation.

The secret? Onshape is cloud-native, which means there’s no need to manage CAD files using a Product Data Management (PDM) system, and designers can access and compare each iteration of a model.

From unique collaborative features to a quickly advancing browser-based 3D modeling experience, Onshape offers a full product development journey that streamlines design from start to finish.

Enhanced Consumer Product Design

Cloud-native Onshape helps teams improve communication, reduce time to market, and

focus on manufacturability.