5:39

If you ever buy a home-brewing gadget from Fellow Products, consider that the employee in charge of developing the company’s products was once an unsatisfied customer.

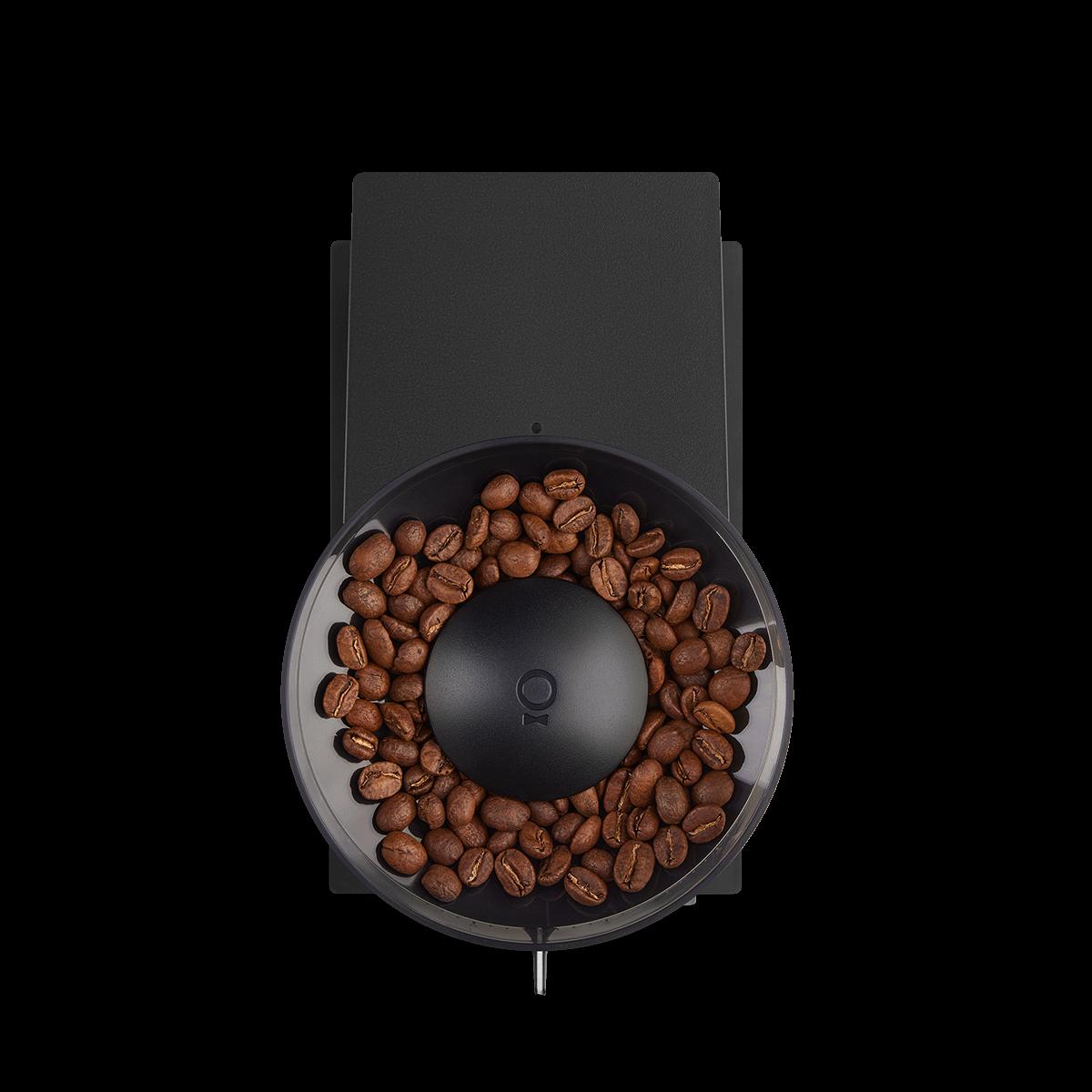

But rather than seeking a return, Nicholas Terzulli reached out to Fellow’s founder and CEO, Jake Miller, and offered suggestions on how to improve the Ode Brew Grinder, which didn’t fit his customized coffee burr. Intrigued by the advice, Miller hired Terzulli to be director of mechanical engineering.

Now the company’s vice president of research and development, Terzulli hasn’t lost that drive to create functional, intuitive, and aesthetically pleasing equipment that makes an ideal cup of Joe at home. He understands what Fellow customers want because he was one himself; he loves nothing more than a perfect cup of coffee at home.

“Once I found out how beautiful coffee could be, it just sent me out on this journey to help other people realize that,” he said.

From a Blank Piece of Paper Comes Innovative Coffee Products

After earning degrees in mechanical engineering and aeroballistics, Terzulli’s professional journey started as a designer of military robotics. From there, he moved on to medical devices. While traveling the world to teach surgeons how to use different instruments he helped design, he visited coffee shops and started wondering how the drink he was savoring was made.

“I got down into a deep rabbit hole about coffee,” Terzulli said. “I realized it’s not actually a bean. It's the seed of a fruit and how you roast it matters. How you grind it matters, and how you taste it matters.”

He got a part-time barista job on weekends, grinding his way through another education.

“I was able to see deficiencies in equipment and had a knowledge of what baristas needed. From there, it was what home baristas needed.”

Applying his understanding of fluid mechanics and fluid dynamics, he was soon fixing high-end machines and thinking of ways to improve and develop grinders, burrs, and other brewing equipment.

After joining Fellow, Terzulli managed an engineering team that also did a little bit of everything else, including copywriting and marketing. Eventually, he got the freedom to focus only on research and development. He’s charged with improving upon Fellow’s industry-recognized coffee maker, kettles, grinders, and other products, as well as dreaming up new ones.

Even though a shortage of microchips and microcontrollers – caused by the global supply chain snarl during COVID-19 pandemic – is no longer an issue for Fellow, Terzulli said he’s always mindful that the production line must always keep moving.

Then there are niche challenges, such as the coffee industry’s current focus on burr design. A burr is a blade in a coffee grinder, and it smashes beans into uniform particles.

“Burr design is this black-box mystery. ‘How do you actually make them? How do certain burr designs affect the flavor profile of the cup?’ I could do an entire Ph.D. just on burr design.”

Terzulli added: “My passion is solving really hard problems. That's what gets me excited. My bosses are like, ‘Hey, we want to do this thing that has all these crazy functions and features.’ And I'm happy I get a blank piece of paper and get to figure out how to crack it. It’s so awesome.”

From Cloud Capabilities to Customer Service: Onshape Fills Fellow’s Cup

The blank piece of paper is figurative, but Fellow’s use of Onshape Professional is the literal way Terzulli and colleagues are solving those hard problems. Onshape Professional is a fully cloud-native CAD and PDM package with integrated simulation and rendering tools.

Terzulli has used every kind of CAD program since college, but it was six years ago, while working for another coffee equipment manufacturer when he had the “a-ha” realization of Onshape’s potential. A fellow engineer had designed a mechanism on his iPhone, using Onshape’s mobile app, and Terzulli was sold.

His appreciation for Onshape continues at Fellow. Whether it’s getting help from an Onshape customer experience team member late at night or knowing that with Onshape PDM “everything is there to just let you do the work you want to do” – Terzulli enjoys how Onshape makes his work easier.

That includes the ease with which he can pick up a project anywhere at any time thanks to Onshape’s cloud capabilities.

“You never have to save anything. Many times, when I used another CAD platform, I’d be working for an hour or two and then I’d have a crash. Hours of work were gone, and I’d have to start over,” he said. “With Onshape, I can leave the CAD on a computer screen at my office and drive to my house to open up another computer and keep working on that CAD without any headache.”

Terzulli also feels assured by Onshape’s timely platform updates.

“With other CAD platforms, you don't get a new drop for a year,” he said. “And then you have to deal with all the bugs that are in that platform for a full year. Onshape is by people who are actually making CAD for engineers. Also, I never thought I would say this in my life, but I like the software-as-a-service aspect of Onshape, where you don’t have to get locked into certain things or pay hefty licensing fees to get what you need.”

Becoming a Better Coffee Product Designer, Thanks to Onshape

Terzulli and team recently used Onshape to design Fellow’s latest top product: Aiden, a precision coffee maker.

“In my opinion, it is the most advanced capable coffee brewer ever developed for the home,” he said. “The product you see when you go to Crate & Barrel or Williams-Sonoma, or if you buy it directly from us, was entirely designed in Onshape.”

One of the principal engineers on the Aiden project –0 who Terzulli calls “one of the most brilliant mechanical designers I’ve ever worked with” – was a “diehard” fan of another CAD platform. The engineer was reluctant to change CAD platforms, but Terzulli asked him if he knew that PTC had acquired Onshape. The engineer agreed to give Onshape a try and was soon a convert. Many of the mechanisms on Aiden exist thanks to that engineer’s switch to Onshape, Terzulli said.

Terzulli looks forward to using Onshape on more projects.

“Onshape helped me become a better mechanism designer,” he said. “I always thought I wasn't capable, or I didn't have the knowledge to design certain things. But it just clicked with Onshape. For example, we have this project called the Slide Lid. It’s this hermetically sealed piece of drinkware that has a sliding mechanism. You can open and close it with one flick of your thumb. I designed that entire thing in Onshape. I had nothing to lose, and it turned out awesome.”

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Automotive & Transportation

Zero Crashes, Limitless Collaboration, One Connected Workflow With Cloud-Native Onshape

12.04.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more