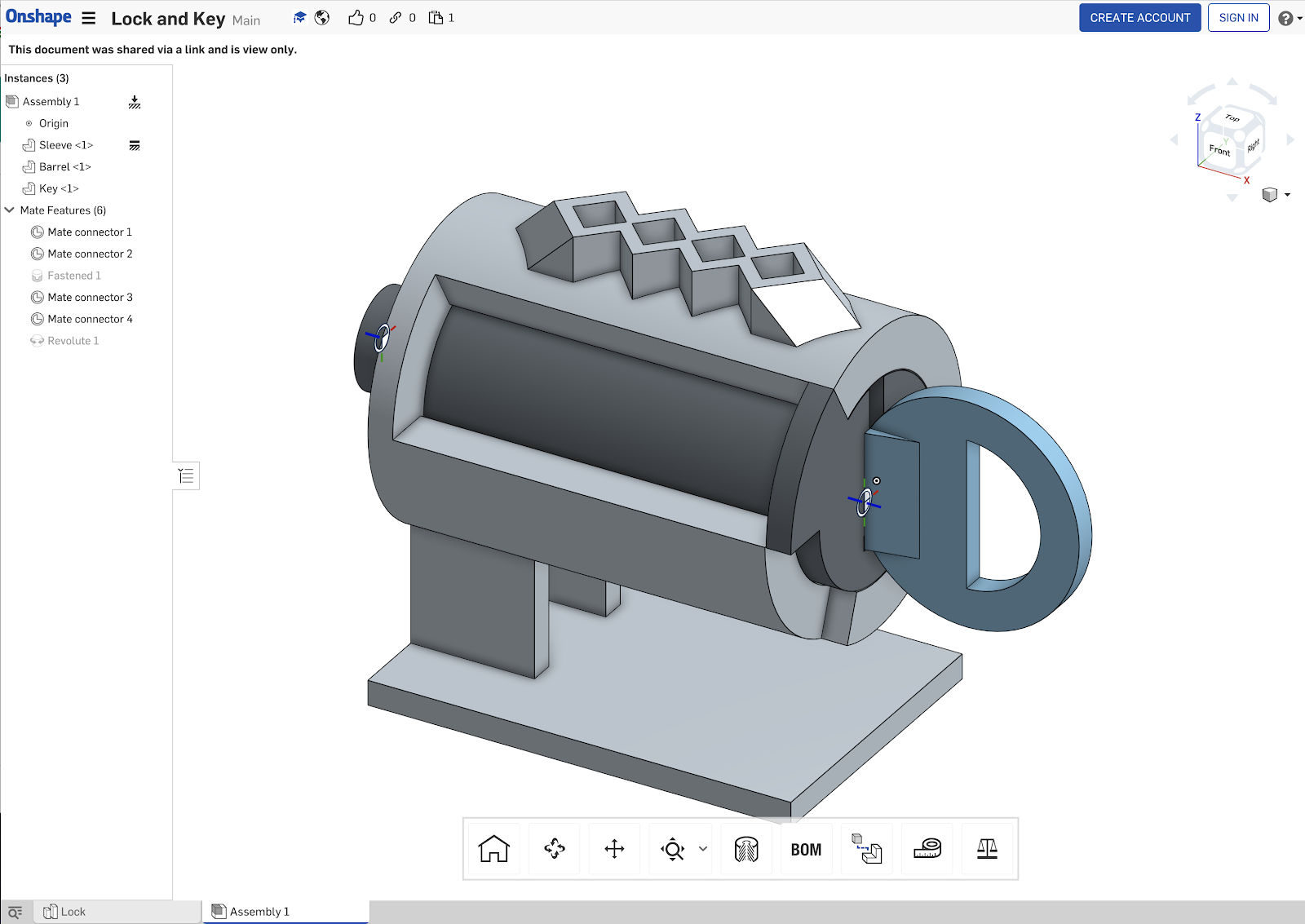

On the first day of their 3D design class, Providence Engineering Academy director Rodney Meadth presented students with objects of different colors, shapes, and sizes he’d produced with a 3D printer. He arranged the mystery objects on a table at the front of the class and announced, “Okay, guys. If you can assemble this, it’s a machine that you are familiar with. Who can figure out what this thing is and how it fits together?”

Within five minutes, an eager volunteer assembled the pieces into a key-and-pin cylinder system similar to the lock used in a home or office door. To open the lock, a key is inserted into a barrel that contains sliding pins of varying lengths. The right key is perfectly aligned to elevate the pins, which allows the key to turn.

The Onshape 3D model of the lock-and-key system that was later produced on the Providence School's 3D printer.

Meadth had the whole class at hello. “Just like that, the students are instantly invested on day one,” he says.

Providence Engineering Academy is the STEM program at Providence School, a Christian college preparatory school (K-12) in Santa Barbara, California. In addition to 3D design, the curriculum includes logic and programming, robotics, mathematics for engineers, statics, and aerodynamics. The competitive high school program aims to prepare students for careers in math, science, and engineering.

“We have a strong academic culture where it’s cool to be smart,” Meadth says. “Most students are pretty good about seeing the gift that education is, and honoring that. Everyone applied to be in this program. They had to convince me that they wanted to be in it. Motivation is not typically an issue around here.”

Meadth calls his students “junior engineers,” reminding them they are preparing for real careers – even while in high school.

Product Design as Community Service

High school students demonstrate their 3D-printed robotic hands to the elementary grades at Providence School.

High school students demonstrate their 3D-printed robotic hands to the elementary grades at Providence School.

As community service is a core component of a Providence School education, Meadth chooses class engineering projects that have a charitable focus. This year’s projects include creating two custom-built pieces of furniture with students first producing quick physical concept models with materials such as Legos and cardboard before designing them more carefully in CAD.

The first project is an adjustable standing desk with a mechanical actuator allowing a teacher to raise and lower the table to standing and sitting heights with the press of a button. The furniture was designed for a specific elementary school teacher who needs such equipment because of back problems. The second project is a computer desk for a wheelchair user at PathPoint, a local nonprofit work training program for people with disabilities. The user will be able to roll up to the desk, press a button and have an iMac move towards them and tilt down so the screen can be easily viewed.

In a recent Foundations of Engineering II class, students also designed and built controllable robot hands that were fully articulated with knuckle joints and thumb joints. The project was demonstrated at the campus science fair, inviting younger students to control the fingers – about eight times the volume of human ones.

“It kind of looked like Optimus Prime’s robot arm on the desk, like a giant,” says Meadth. “We didn’t want the hand to be too small and delicate.”

Exposure to PathPoint and the robotic hand project provided career inspiration for Eva Kilpper, a 2019 academy graduate.

“Being able to turn a creative idea into making a tangible difference in someone’s day-to-day life is the most exciting aspect of engineering,” says Kilpper, now a sophomore studying mechanical engineering at Oregon State. “Eventually, I would like to pursue developing adaptive tech for people with disabilities. Many currently available tools are clunky and inefficient unless they are exorbitantly expensive. I am interested in creating tools, prosthetics, and other aids that naturally fit into the varied lives of the disabled people who would benefit from them.”

“As technology reaches more exciting heights and tools like 3D printers become available to more ordinary people, I’m excited to see what problems we can solve together,” she adds.

Cloud-Based Onshape Boosts Student Collaboration

Providence School's physical education program makes the most of the custom-built workout box system designed by the school's engineering students.

Providence School's physical education program makes the most of the custom-built workout box system designed by the school's engineering students.

For his engineering classes, Meadth has been teaching CAD with the free Onshape Educator plan for the past four years. He was motivated to switch to the cloud-based CAD platform four years ago because of the limitations of when and where his students could use installed file-based CAD software. Onshape requires no installation or IT support. Students can instantly sign up and login with their email address.

“Our old CAD software was very well suited to a high-powered desktop situation, but it doesn’t work on Chromebooks or tablets,” notes Meadth. “There’s a reason why Apple products are so common amongst educators – it’s because they’re light, they’re durable, they’re portable and they’re fast. I’ve got students who bring Macs to school. I have students who use PCs. Onshape just runs on any computer.”

CAD portability and accessibility aside, the teacher stresses that a more impactful reason he prefers Onshape is its real-time collaboration tools. Multiple students can be working together simultaneously on the same CAD model online, a workflow that is not possible with traditional installed file-based CAD systems. Whenever an Onshape user makes a design change, everyone else on the team, including the teacher, can instantly see it.

For a recent Advanced Engineering I class focused on statics, a group of juniors and seniors used Onshape to design two versatile 120-pound wooden boxes that could be used by the Providence physical education department. The nine-piece boxes can be fitted together in different configurations and used as a balance beam, a step-up box, or as part of an obstacle course.

Meadth first had students create paper models to see how the boxes would fit together, and then duplicated the process in Onshape. “We had multiple students working on the different plywood faces at the same time,” Meadth says. “The two faces that meet on every side around the whole box come together in a puzzle-piece style. There’s a male-female connection on every edge, but if parts don’t line up, it doesn’t work. You only have to mess it up in one place, and you’ve ruined the whole thing.”

Collaborating in Onshape in real time, the students were able to “spot straightaway” when a mistake had been made with one piece, saving inevitable headaches and frustration later.

Remote Classroom Collaboration During COVID-19

Providence Engineering Academy director Rodney Meadth displays his students' physical aircraft model made from the CAD model designed in Onshape.

Providence Engineering Academy director Rodney Meadth displays his students' physical aircraft model made from the CAD model designed in Onshape.

In the spring of 2020, due to COVID-19, Advanced Engineering II students had to unexpectedly finish the school year remotely from home, including design work on their powered tethered aircraft project.

“Being asked to complete the project from home was not the situation that anyone wanted,” Meadth wrote in the school blog. “You can’t choose the hand you’re dealt, but you can play it to win every time. After all, what is engineering about if not solving problems?”

Because Onshape can be accessed remotely on any device simultaneously with others, the four teams were able to continue uninterrupted, collaborating in pairs in real time.

The students communicated through email, Zoom, and in-model Onshape comments. They could right-click on a part of the CAD model and write a comment which was then attached to that feature. That helped Meadth better keep track of the students’ progress.

“If someone is working on the design, the model changes before my eyes,” he notes.

Students could work on different parts (such as the wings, undercarriage, fuselage, and tail) and then put it all together in an assembly tab. “If they update their own part, then the master assembly is instantly updated and everyone can see it,” Meadth says.

Once finished, the students sent their designs to Meadth, who printed the fuselages and tails on a 3D printer and created wing ribs with a CNC mill in his garage. He delivered the parts to each team, who put them together, and then the class gathered safely with masks in the school gym to test out their concepts.

Model planes circled the room within a couple of feet of the gym walls, “enough to make any pilot sweat a little,” reports Meadth in his blog. (Watch video of the class test flights here).

Even though the Providence School is currently back to in-person learning, Meadth is confident that Onshape will ensure his students’ education will never be interrupted regardless of future circumstances.

“I don’t have to be worried about anything except the lesson and the design itself,” he says. “We can all just jump on the browser with any device, and students can do their CAD work at home. I don’t have to worry about sending one of our high-powered laptops home with them or if they’re sick or if a pandemic hits. This is just perfect.”

"Over my career, I've used about 10 different CAD programs ranging from computer animation to physics and engineering," Meadth adds. "I think it's very telling that in the last four years I've really just used Onshape."

(To learn how your school can benefit from the Onshape Educator or Onshape Education Enterprise plans, click here.)