03:36

Based in Colorado, FHE designs and manufactures pressure control equipment that makes hydraulic fracturing (“fracking”) operations more efficient and safer for oil and gas workers. In 2015, the multinational company introduced a first-in-the-industry product called the RigLock, a hydraulic wellhead connector that allows personnel to remotely link the well to the pressure control plumbing. With the specialized FHE equipment, workers can securely attach the wellhead connector, lowered by crane, from 100 feet away (see how the RigLock works in this video).

“This process used to involve lowering a worker in a man basket over the wellhead danger zone, called the ‘Red Zone,’ to make a hand connection,” explains Matthew Kibler, a senior mechanical designer for FHE. “There’s a significant amount of heavy equipment hanging and moving by crane, and there’s no real controls. So people were losing fingers and smashing limbs just from the regular human interaction with the equipment.”

“We like to think of ourselves as a safety company,” he adds. “You no longer need to put people in harm’s way.”

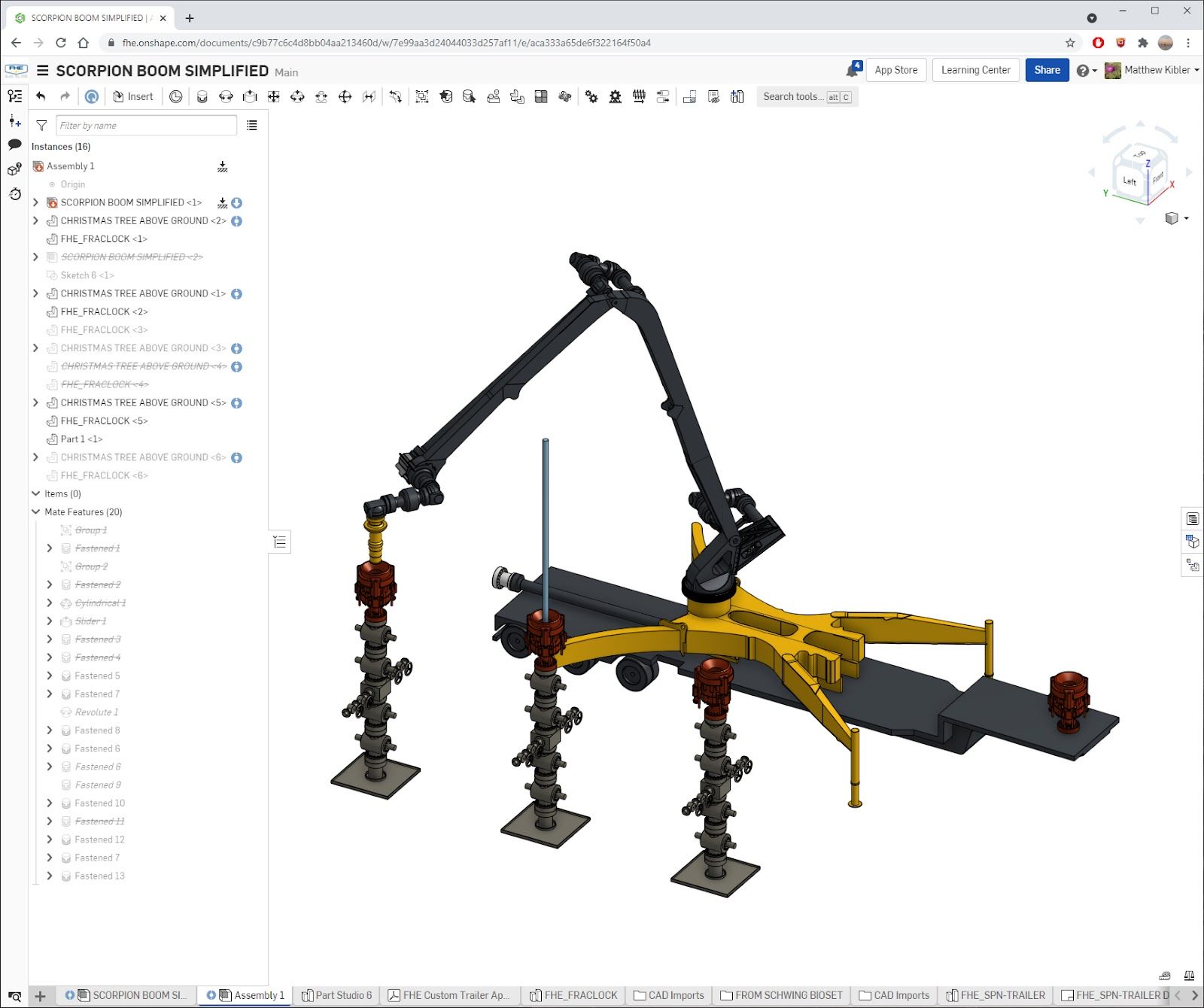

FHE’s latest innovation is the FracLock, an improved wellhead connector that is locked in position by a remotely controlled articulated arm that includes high-pressure plumbing built inside. The system, nicknamed “the Scorpion,” eliminates 85 percent of the iron pipes required in the traditional fracking setup.

The 40-foot-tall articulated Scorpion arm rotates 360 degrees, reaches out over 40 feet from the radial center, and can quickly maneuver from wellhead to wellhead. The FHE system’s versatility maximizes operation time and increases productivity while removing additional injury hazards common to the industry.

FHE is deploying the FracLock system at well sites across the United States, Kuwait and Abu Dhabi.

Onshape’s “Light User” Access Enables Better Third-Party Collaboration and IP Security

To design and build its innovative FracLock system, FHE chose cloud-based Onshape, PTC’s SaaS product development platform that combines a robust CAD system with built-in data management and real-time collaboration tools .

FHE’s product development team currently has 11 full-time Onshape users and 135 light users. Onshape’s Enterprise plan allows companies to purchase flexible and cost-efficient “light user” subscriptions for team members or external partners who only occasionally need to access the CAD model. FHE regards this business model as the most economical and effective way to collaborate with the dozens of vendors who manufacture parts for the RigLock and FracLock systems.

“We have lots and lots of vendors and very few designers,” notes Kibler. “It’s the opposite situation of most companies, which will have lots of engineers or designers and very few vendors. Onshape’s magic is that you can create a separate workspace to share with your vendor. They can export this workspace and then put the geometry into their CAM systems. All I have to do is email them the workspace link and as long as they have the right permissions, they can see our parts.

Kibler adds that Onshape’s secure Sharing feature helps the company better protect their proprietary designs if a business relationship with a specific vendor ends.

“What happens if I don’t want a vendor to be able to see our part anymore? With Onshape, it’s as easy as going into the Document and deleting their permissions so they no longer have access. These type of sharing characteristics are absolutely imperative to the way that we manage communications with our many vendors,” he says. “Onshape really is the next generation of what CAD can and will be, and is leading the way for what collaborative design software looks like.”

Get Your Copy of “The New Collaboration” eBook

Interested in learning more about how forward-thinking companies have benefited from switching to a cloud-based Software-as-a-Service (SaaS) CAD platform?

In this eBook, you’ll be introduced to a brand new class of real-time CAD collaboration and sharing tools, engineering productivity features made possible only by a cloud database architecture.

Cloud-based CAD and data management are no longer a nice-to-have technology, but a must-have technology. Download your copy of “The New Collaboration: A Guide to Transforming Product Design” today and find out why!

Guide To Transforming Product Design

Learn how Business Leaders use cloud-based CAD and real-time Productivity tools to improve teamwork

Latest Content

- Case Study

- Automotive & Transportation

Zero Crashes, Limitless Collaboration, One Connected Workflow With Cloud-Native Onshape

12.04.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more