2:44

(Note: On Feb. 11, 2019, Heuresis changed its company name to Viken Detection.)

Most of you have witnessed this scene on one of those cop TV shows: Police raid the apartment of a suspected drug dealer and proceed to rip his couch, pillows, mattresses and walls to shreds as they search for illegal contraband. That’s the old way of doing business.

The new way of searching a suspect’s apartment or vehicle (presumably with a warrant) is much cleaner. Less broken furniture and drywall. Quicker results finding the goods.

Heuresis, the pioneer developer of handheld x-ray imaging instruments for law enforcement and security professionals, makes the HBI-120 imager that can “see through steel.” You can watch how it works in the video below:

The HBI-120 has safety interlocks, a built-in video camera and flashlight. The instrument can also be mounted on a robot and operated remotely via USB cable, Wi-Fi or Bluetooth radio control.

The HBI-120 Handheld Backscatter Imager helps law enforcement quickly detect hidden drugs, weapons and other illegal contraband. (Source: Heuresis)

Although police operations are a major focus for Heuresis products, the company also has security contracts with U.S. Customs and Border Protection (CBP), the U.S. Department of State, and the World Customs Organization. Specifically, the U.S. Department of State selected Heuresis to supply non-intrusive detection systems used to detect weapons, organics and other anomalies in vehicles at border and security checkpoints in Egypt.

Onshape’s Real-Time Data Management

A pioneer in law enforcement technology, Heuresis designs its portable x-ray devices in Onshape, the leading 3D cloud platform for CAD and data management.

Based in Massachusetts, Heuresis uses Onshape as its primary CAD and data management platform to speed up product development.

“Onshape gives me the ability to instantly check on the status of a design,” says Howard Kellogg, lead mechanical engineer at Heuresis. “It’s helpful for me to stay up to date on a project in real time and provide feedback to the team. We don’t even need to have informal design reviews. We can just see each other’s progress anytime.”

With Onshape’s real-time data management, whenever an engineer makes a change or edit to their 3D CAD model, everyone on the design team instantly sees it. A comprehensive Edit History also records who made what changes and when, allowing the team to return to any prior state of the design at any time.

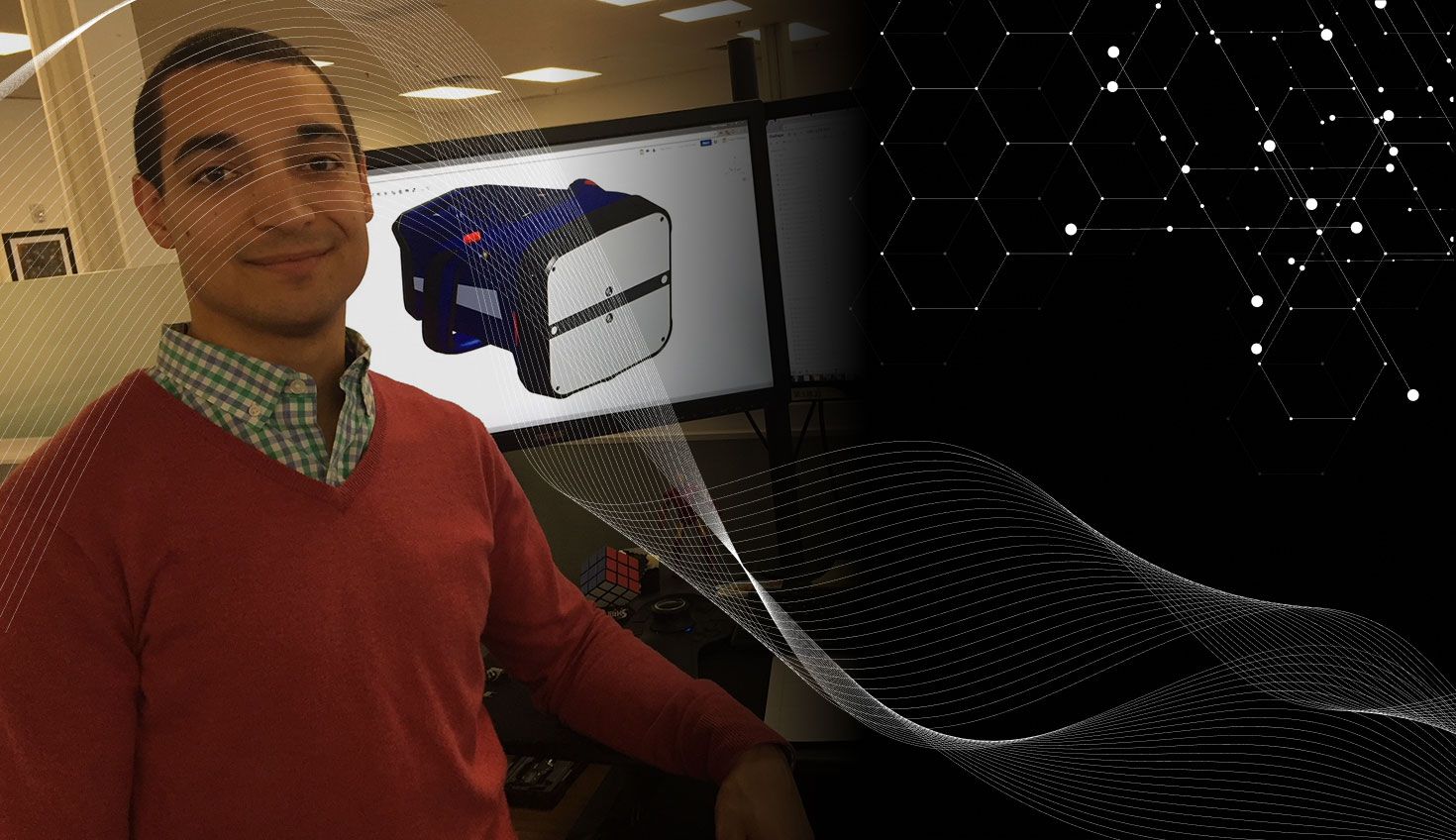

Howard Kellogg, lead mechanical engineer at Heuresis.

Kellogg adds that he especially appreciates Onshape’s reliability and resistance to CAD crashes. Because of the platform’s cloud database architecture, the system can immediately start up new servers if there is a disruption and let engineers continue working where they left off.

“Onshape is just so much more stable,” Kellogg says. “We no longer have to worry about references getting lost or individual files getting corrupted. When we were using SOLIDWORKS, it would sometimes crash and we’d have to deal with recreating lost work.”

“Whenever I’d lose work because of a crash, I’d tell myself the silver lining was that I could do it faster and better the second time around,” he adds. “But that’s still time you’re not spending moving forward. Onshape has put crashes behind us and lets us focus more on our product development.”

The CAD Migration Station

Find everything you need to know about transitioning from SOLIDWORKS to Onshape.

Latest Content

- Case Study

- Consumer Products

BOA Technology: Redefining Outdoor Fit Equipment with Cloud-Native Onshape

11.03.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more