The Challenge

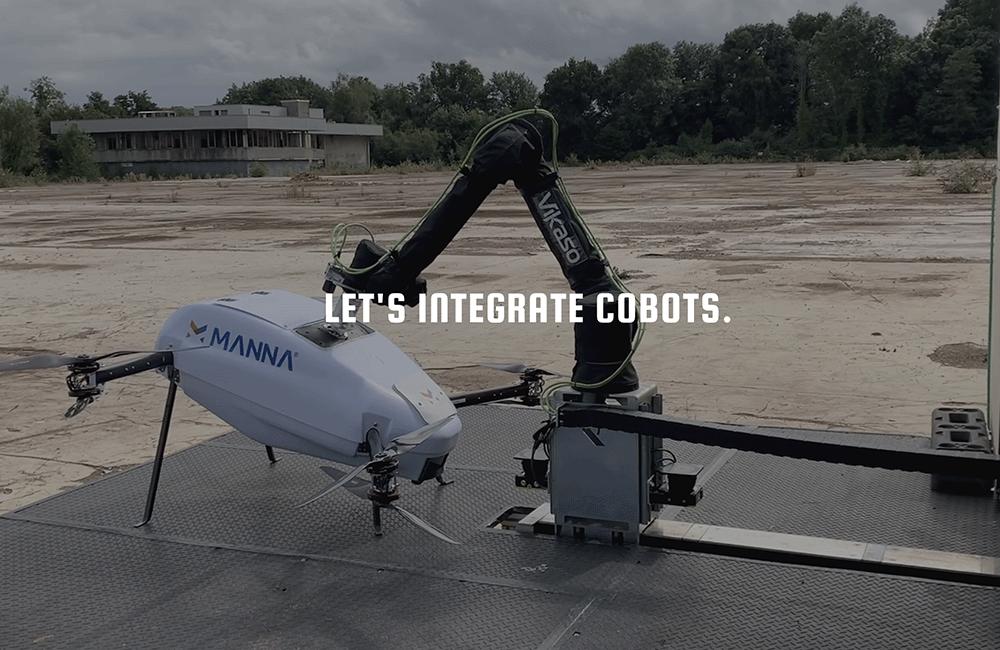

Based in the UK, VIKASO is an industrial automation startup specializing in integrating collaborative robots (“cobots”) into manufacturers’ production lines to automate repetitive tasks. VIKASO’s customers include companies of all sizes, ranging from fellow startups to iconic global brands such as Rolls-Royce, BMW and MINI. The cobots are designed to work alongside humans, accelerating the assembly line. Preparing to quadruple its engineering team in 2020, VIKASO was seeking a CAD and data management solution that could resolve the version control issues it was experiencing with only one engineer collaborating with suppliers and customers. The company also desired a more cost-effective platform than its previous file-based CAD system, which required high-performance workstations just to run the software.

Results

- VIKASO reports that cloud-native Onshape’s real-time collaboration tools has sped up communication by 60 to 70 percent between its core design team and external partners. Customers can now monitor the latest designs 24/7 without the pre-cloud delays of sending updated files back and forth.

- Onshape’s device-agnostic platform has saved VIKASO an estimated 50% in hardware costs. The company no longer needs dedicated high-performance workstations solely to run CAD.

- VIKASO relies on Onshape’s built-in PDM system to allow multiple engineers to simultaneously edit the same designs without overwriting each other’s work.

Transparency is very important to us. Onshape’s Comments feature lets us easily record why we’ve done what we’ve done – so we can still work at a rapid pace, while taking on some really risky, innovative and disruptive projects.’’

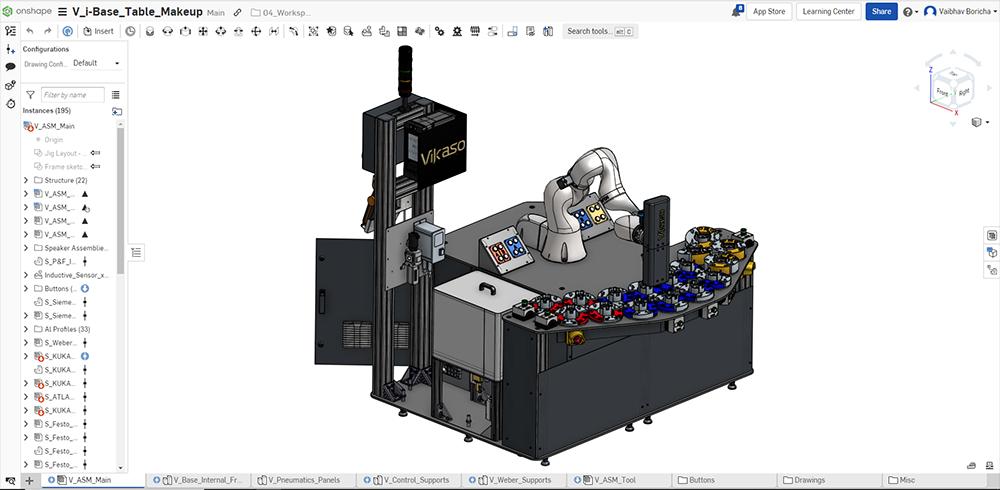

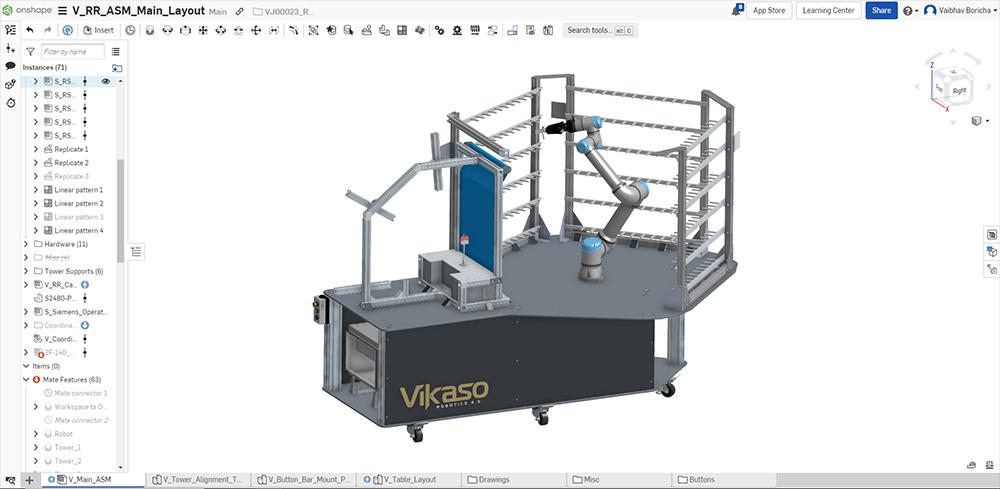

VIKASO engineers specialize in making sure robots can collaborate alongside human workers on the factory floor.

So it’s not a coincidence how much human-to-human collaboration is involved before a new automation system can be put into place.

Based in the UK, VIKASO is an industrial automation startup that integrates collaborative robots (“cobots”) into manufacturers’ existing production lines to automate repetitive tasks. VIKASO’s customers include companies of all sizes, ranging from fellow startups to iconic global brands such as Rolls-Royce, BMW and MINI.

Up until very recently, robot workstations were separated from human workers by physical barriers because of safety concerns. Due to advances in force and torque sensor technology, however, a new class of cobots can instantly detect collisions with any part of the robotic arm to reduce the likelihood of injuries. Members of the VIKASO engineering team have extensive career experience with industry-leading robotics companies, enabling them to develop innovative cobot integrations from the manufacturer’s point of view.

Furthermore, at the core of VIKASO’s product design philosophy is the consideration of the entire application lifecycle during each stage of development. For example, when building the first CAD model, engineers are also discussing potential maintenance options and how those might impact the design.

The company’s mission statement, “The VIKASO Cobot Journey,” includes a commitment to agile development:

“We do not believe in sequential engineering and waterfall-type project management. Our processes are inspired by agile software development and we are designing them to be fast, robust and flexible – bringing mechanics, electronics, controls and safety to the same table from the start for every cobot integration,” the declaration reads. “This way, we have constant transparency and avoid inefficient re-planning or dead ends.”

Seeking Version Control for an Expanding Team

According to VIKASO Director Vaibhav Boricha, embracing an agile product development mindset includes an ongoing willingness to explore new technologies and tools to tackle inefficiencies.

In 2020, as the growing company needed to expand its design team from one mechanical engineer to four, Boricha began testing alternative CAD and data management platforms to better address their version control issues. He recalls that the status quo of manually keeping track of the latest design versions through a file-naming convention – naming files V1, V2, V3, etc. – was a system prone to mistakes.

“With version control, we used to have problems even with one engineer because human error always comes into play,” says Boricha. “The biggest pitfall was not being able to go back to previous versions quickly. And secondly, there’s the problem of somehow forgetting what you did in which version. We had no ability to record notes for individual versions. We would name a file V3, but what was V3 about? What changed from V2 to V3?”

One of the biggest reasons VIKASO decided to switch from their old file-based CAD system to cloud-native Onshape was its automatic version control. Onshape’s built-in Product Data Management (PDM) system, included in the cost of a yearly subscription, doesn’t require engineers to check in and check out designs from a vault. Multiple users can simultaneously edit the same document, seeing each other’s updates in real time with no risk of overwriting each other’s work.

Onshape’s comprehensive Edit History also records which engineer made which design change and when, allowing the team to instantly revert to any prior iteration with a mouse click.

“Transparency is very important to us,” Boricha says. “Onshape’s Comments feature lets us easily record why we’ve done what we’ve done – so we can still work at a rapid pace, while taking on some really risky, innovative and disruptive projects.”

Speeding up Communication with External Partners

Parallel to the productivity boost that their cobots make on the factory floor, Boricha notes that VIKASO has significantly improved its own efficiency when collaborating with its customers and suppliers on automation projects. He estimates that Onshape’s Sharing feature, which gives clients real-time access to the latest design changes, makes the communication process 60 to 70 percent faster.

“We give our customers a live link of our document and just tell them, ‘Keep an eye on it every week and you will keep seeing regular updates.’ And it's beautiful since we now don't have to email files back and forth,” Boricha says. “If everybody is not using the same CAD system, then you have to convert them to STEP files before attaching them to an email. If the files are too big, you can't send the attachment. You then have to ask them to send you the data exchange link, and then upload the design. So Onshape is easily 60 to 70 percent faster.”

“Onshape’s collaboration tools just streamline every stage of our development process,” he adds. “From getting a design in place, getting that design approved with our customers, getting it ready to be manufactured, and then getting it manufactured. That entire chain of events becomes much easier for us because we don't have to export individual documents.”

SaaS Platforms are Budget-Friendly for Startups

Back when VIKASO quadrupled its engineering team, adopting cloud-native Onshape resulted in an immediate 50 percent savings in hardware costs. Because Onshape runs on any computer or mobile device (iOS or Android), it was no longer necessary to purchase dedicated high-performance workstations solely to run CAD.

Given the company’s budget limitations as a startup, Boricha was seeking a Software-as-a-Service (SaaS) product design platform offering an annual subscription versus having to purchase expensive on-premise CAD licenses upfront.

“We just didn’t have an incredible amount of money laying around to buy more perpetual licenses. We first found Onshape when we were looking for a subscription model, and all the other added value – not having to manage servers or maintenance, securing and backing up our data – was the cherry on the cake,” he recalls. “A SaaS model gives us breathing room. The whole idea of buying perpetual licenses is not something we’d want to pursue at this stage of the company.”

“Even in the future, I would never choose a perpetual license because it does not give us any flexibility,” Boricha adds. “If there is a better technology that comes out two years from now, then what do we do? We’d be stuck with those licenses that we invested $20,000 to $50,000 in. Beyond the subscription model, Onshape is saving us money in other ways – such as in the time we save sharing information with our clients and just in the whole development process.”

Anticipating Future Growth with Onshape

Eyeing the goal of doubling VIKASO’s operations over the next few years, Boricha says he appreciates Onshape’s quick procurement and onboarding process.

“We got our hands on Onshape to try immediately within a day. Everything was very streamlined and very easy. We were not talking to distributors of Onshape licenses. We were talking to Onshape directly,” he says. “On the technical side, the Onshape team is always available when we need them to be available. There’s also a quick learning curve. One of our new hires was able to learn the basics of Onshape on his first day.”

“It’s a CAD platform that VIKASO can really scale up with,” Boricha adds. “So if we want to go from a team of 5 to 10, from 10 to 20, from 20 to 40, Onshape is by far the best solution that we could ask for.”