A Manager's Guide for Soliciting Stakeholder Feedback During Design for Manufacturing (DFM) Process

This guide offers suggested ways to improve communication within your supply chain. Feedback from DFM reviews impacts everything, including manufacturing, costs, timing and eventual customer satisfaction which is why it’s so critical to be a good listener. Asking the right questions can help balance agility with consensus in creating the best manufacturing process possible to bring your product to market.

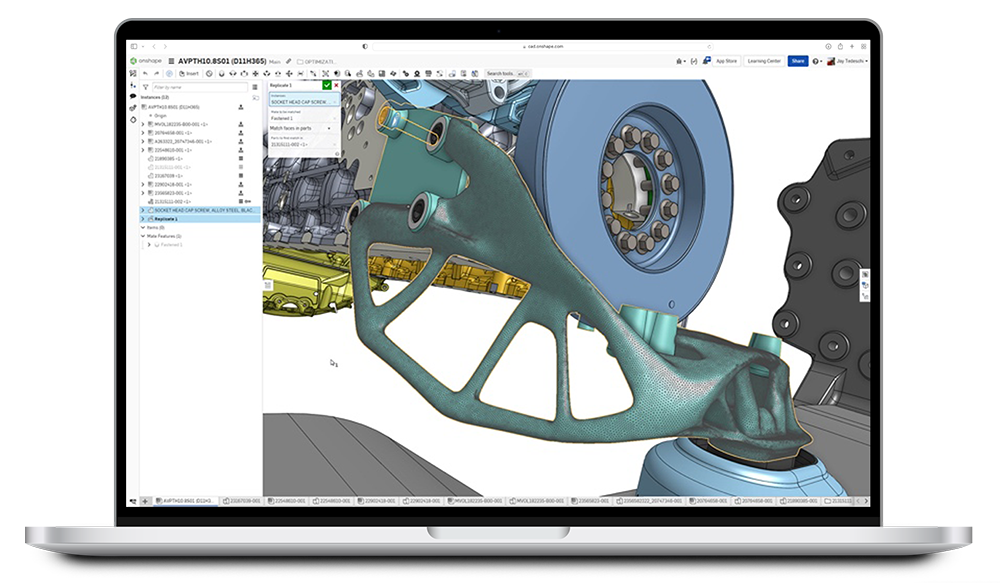

"Making sure our vendors have the most up-to-date drawings provides immediate savings. Anytime we get a manufacturing mistake, it could cost several thousand dollars... the clarity that Onshape gives us in our communications with vendors is invaluable.”

Onshape’s Enterprise Light User Access Enables Better Third-Party Collaboration and IP Security

Knowing Who and What to Ask?

A Manager's Guide to Common DFM questions

Most product design teams are isolated during the design process and do not have enough contact with other departments. When the flow of information and feedback are restricted, it can lead to problems with the final product. This is where cross-functional design comes in. Cross-functional design is the process of having members from different departments involved in the product’s lifecycle. As a result, product designers work better when they have input from other team members on different aspects of their process, like engineering, marketing or sales. Only Onshape makes it easy for design teams and manufacturing teams to easily and securly communicate and collaborate in real-time at any phase of the design process.

With Onshape you can easily share models via a URL, providing assembly line team members with real-time access to current models. Removing the communication and collaboration barrier, here are some question you can ask to streamline the DFM review process.

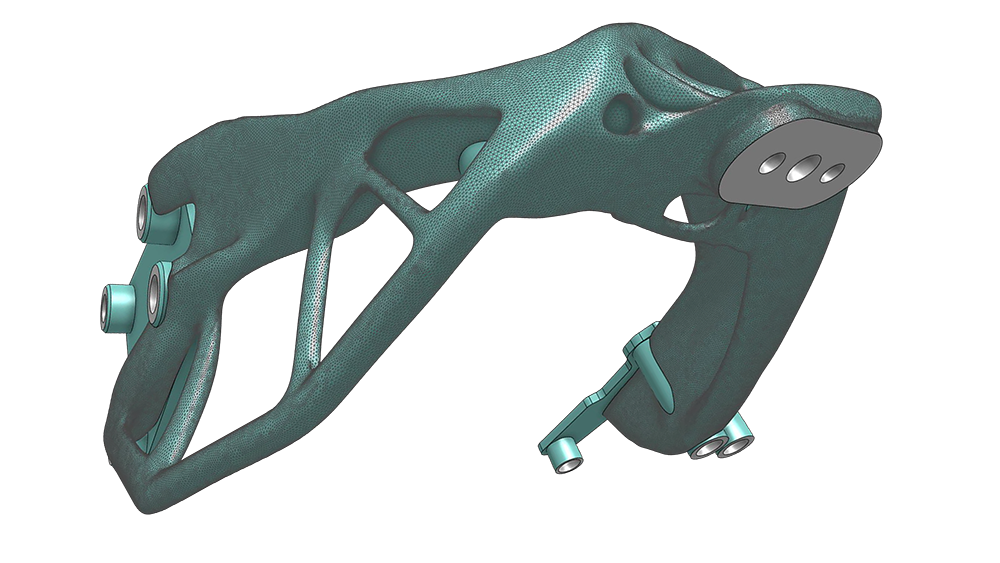

When designing products, consider the manufacturability of your design right from the outset.

Manufacturing Suppliers and Production Teams

DFM reviews focus on reducing production time and costs while ensuring products meet requirements, regulation, and quality standards.

Here are some questions your can ask of assembly and installation team your manufacturing suppliers and production teams during DFM reviews

Review all the questions to ask your manufacturing suppliers and production teams during DFM reviews.

Review your team’s usage of best DFM Practices.

Assembly and Installation Teams

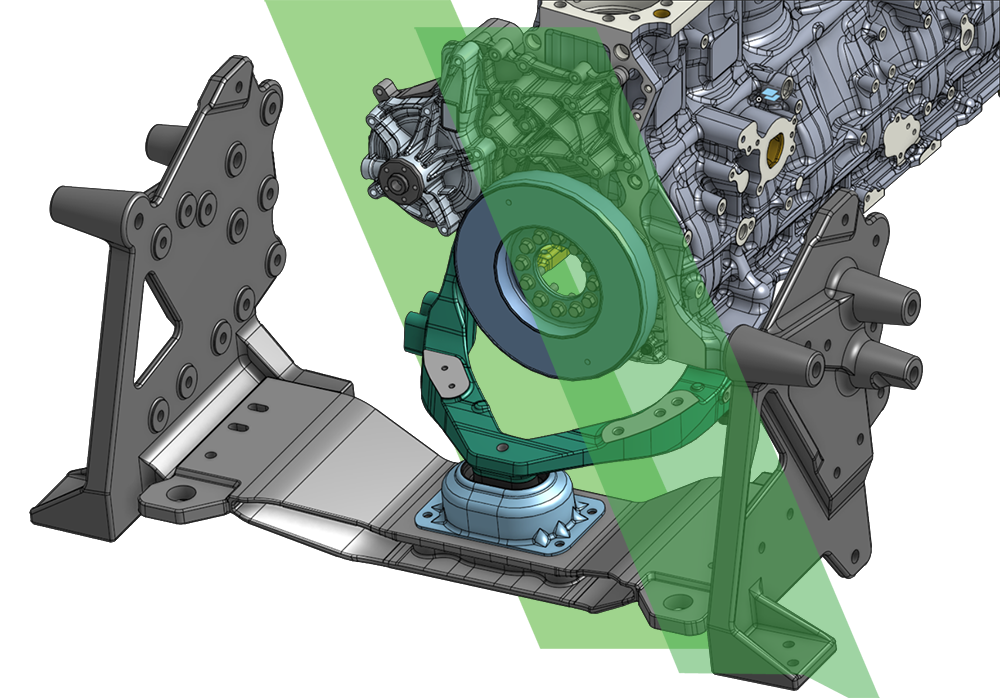

DFM reviews can be limiting as they often exclude input from downstream teams such as those handling the product’s assembly and installation orders. Discussions with these teams can be abstract as they occur before the product is created. Traditionally using PDF documents to relay specs and instructions have been as good as it gets, making the decision process about the product assembly harder and more prone to quality issues.

Here are some questions you can ask assembly and installation teams during DFM reviews

Review all the questions to ask your assembly and installation teams during DFM reviews.

Review your team’s usage of best DFM Practices.

Logistics, Packaging and Distribution Teams

Good product designs also incorporate feedback on the packing and delivery of the product. The final packing has to be robust including transportation details such as stresses like vibrations and even loading and unloading instructions.

Here are some questions you can ask your logistics, packaging and distribution teams.

Review all the questions to ask your logistics, packaging and distribution teams during DFM reviews.

Review your team’s usage of best DFM Practices.

Onshape is a more collaborative and inclusive design platform that enables you to have more robust DFM reviews. With Onshape, you can securely share view-only CAD models and drawings with manufacturers, enabling you to host real-time DFM reviews with multiple users simultaneously. Onshape provides communication and collaboration capabilities, such as: follow mode and task assignments, with tools that allow anyone who is a part of the DRM process to ask questions through comments, and markups.

Built for the cloud, Onshape’s unique architecture enables multiple users to concurrently communicate and collaborate on the same model, at the same time. No matter how dispersed your design and manufacturing teams are, Onshape provides the best tools to enable more robust DFM reviews earlier in the development cycle.

ONSHAPE IS THE #1 FASTEST GROWING CAD SOFTWARE IN THE WORLD

Sign up for a free Onshape Professional Trial and experience more effective communication today!