03:10

For product designers, the transition from CAD to CAM has traditionally been a point of heavy friction. Design intent does not always align with manufacturing constraints, leading to costly revisions, miscommunications, and production delays. In an effort to avoid these outcomes, designers should have the ability to validate manufacturability and improve collaboration with the manufacturing teams—all without leaving their CAD environment.

The Persistent CAD to CAM Challenge

Historically, CAD and CAM have been completely disjointed, requiring engineers to export files from their CAD software to a separate CAM system for toolpath generation. This manual transfer caused a plethora of issues, slowed changes, and led to costly last-minute surprises when manufacturability problems were discovered too late.

Newer systems have integrated CAD and CAM within the same software, reducing the need for exports—but collaboration remains a challenge. Designers and machinists still work in silos, with limited to nonexistent real-time communication. Further to this, changes to the design often require manual updates to toolpaths, leading to delays, inefficiencies, and increased costs.

What if instead of just merging CAD and CAM, the workflow itself became truly connected and collaborative?

Enter Onshape CAM Studio: Cloud-Native CAD + CAM

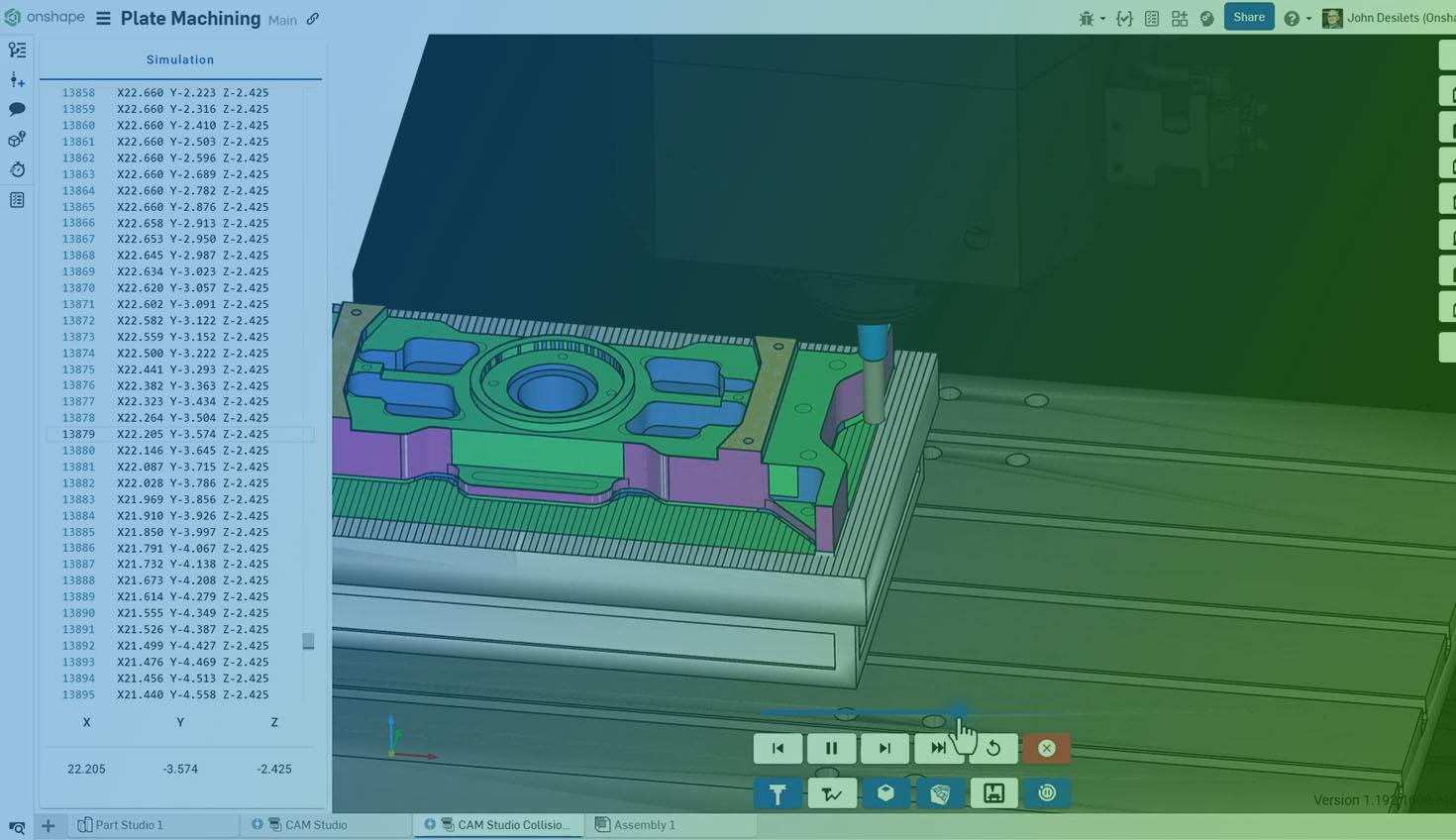

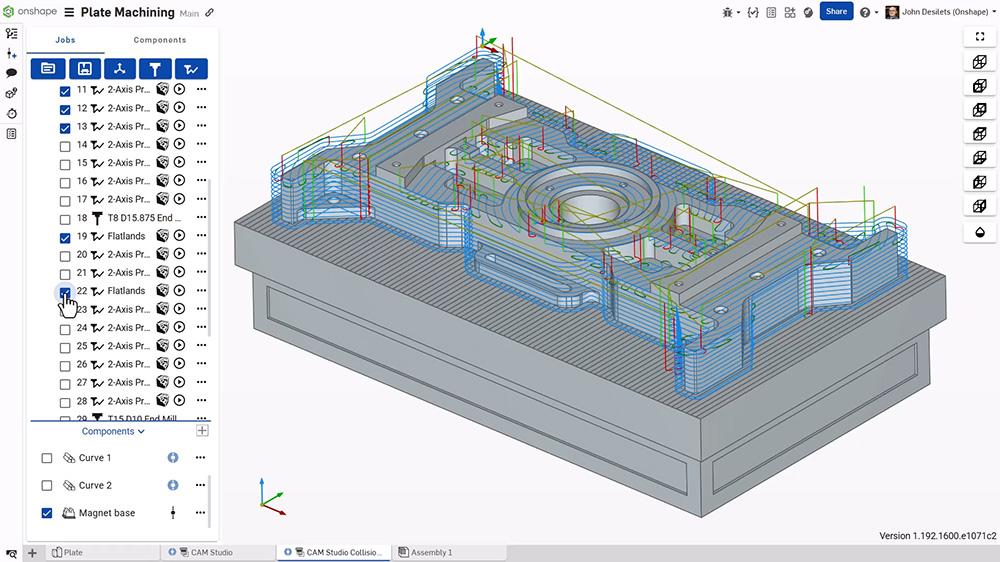

Onshape CAM Studio eliminates these inefficiencies by providing zero-export CAM, meaning you never have to leave your CAD system to generate toolpaths. By integrating CAM directly into a cloud-native CAD environment, Onshape CAM Studio enables:

- ✅ Instant Manufacturability Feedback – Designers can test machining strategies in real-time, reducing the risk of unmanufacturable parts.

- ✅ Seamless Collaboration – Teams work from a single source of truth, allowing manufacturing engineers and designers to refine parts together—without endless file transfers.

- ✅ Faster Prototype Cost Estimation – Onshape CAM Studio helps designers predict complexity early, so cost expectations become clearer before manufacturing begins.

- ✅ No Software Installation – Since it runs in the cloud, Onshape CAM Studio works directly in the browser, removing the need for IT setup, software updates, or hardware constraints.

Real-Time Design & Manufacturing Collaboration

With traditional CAD-CAM workflows, manufacturers are often brought in too late in the process, leading to costly redesigns. Onshape CAM Studio eliminates this bottleneck by allowing simultaneous design input from all stakeholders. A manufacturing engineer can assess toolpaths while a designer refines a part—without ever emailing files or exporting models. And perhaps the best part: all changes are tracked and can be rolled back at any time.

💡 Example: A manufacturing engineer can adjust fillet radii for optimal machining (minimize tool change/accommodate tool crib) with near-instant toolpath updates, while the designer can ensure form and fit at the assembly level at the same time.

The Future of CAD and CAM: Fully Connected Workflows

By bridging the gap between design and manufacturing, cloud-native CAD and CAM unlock new efficiencies:

- Fewer design iterations – Catch manufacturability issues before the first prototype.

- Lower costs – Reduce wasted material and machining time.

- Faster time to market – Design, validate, and machine parts with minimal delays.

With Onshape CAM Studio, designers and engineers can move from concept to production faster than ever before—all within the same cloud-native platform.

Ready to Eliminate the Design-to-Manufacturing Gap?

If you’re tired of file exports, siloed work, version control headaches, and unnecessary design revisions, it’s time to rethink your workflow. Try Onshape CAM Studio today and experience how truly integrated CAD to CAM can streamline your manufacturing process.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Industrial Equipment & Machine Design

Reframe Systems: Transforming Homebuilding with Digital Automation and Cloud-Native Onshape

09.25.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more