Onshape Sheet Metal

Design cost-effective, lightweight, and durable sheet metal parts with Onshape

Design cost-effective, lightweight, and durable sheet metal parts with Onshape

Why design sheet metal parts?

Sheet metal designs are favored due to their versatility, cost-effectiveness, and durability. This process allows for the creation of a diverse range of products, catering to industries like automotive, aerospace, and consumer electronics. Sheet metal's ability to be easily cut, bent, and shaped, combined with its strength-to-weight ratios, makes it an ideal choice. Onshape is reshaping and improving the way designers tackle the inherent challenges associated with this type of product.

Key Features

Flexible Modeling

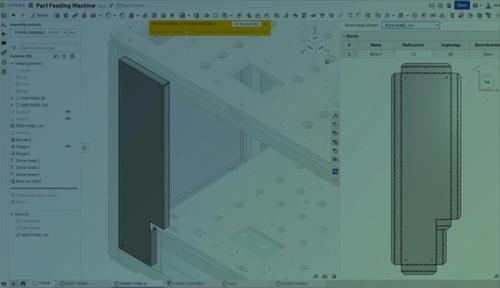

In Onshape, you can initiate a sheet metal design using several methods: you can convert a solid part into sheet metal; design from a flat sketch, then fold; use flange tools to add edges and features; or directly import and adapt existing sheet metal designs.

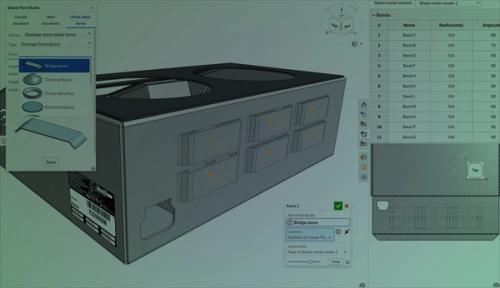

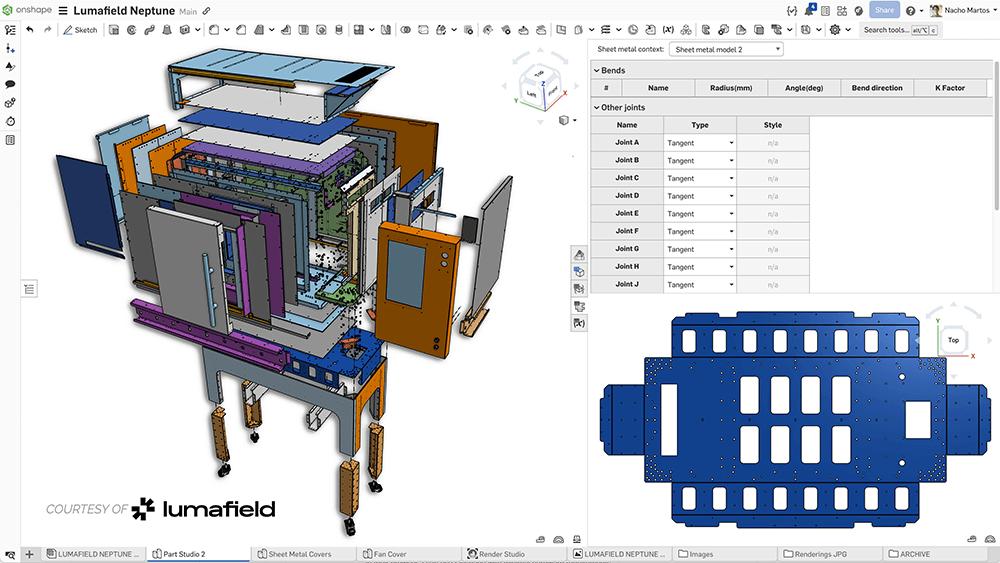

Simultaneous Sheet Metal

With Onshape, users can simultaneously create and preview flat patterns. This visualization of the flattened design helps streamline the manufacturing planning process. Additionally, the platform supports direct exports to standard formats like DXF or DWG for fabrication needs.

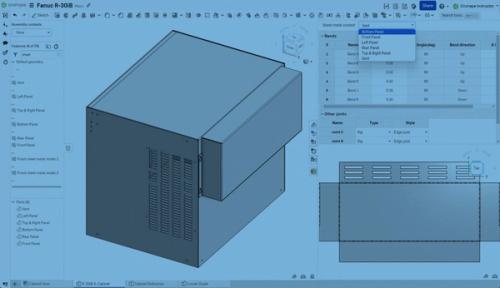

Precision Designs

Use sheet metal bend parameters like K-factor, bend allowances, and bend deductions, to ensure accurate flat pattern generation for your sheet metal designs. It's crucial for product manufacturability, ensuring precise dimensions and fit, by accounting for material stretch and compression during bending.

Advanced Collaboration & Version Control

Integrated within every aspect of Onshape's framework, is a robust advanced collaboration toolset. Design teams can effortlessly share, comment, and maintain version histories. This holistic approach reduces miscommunication, enhances team synchronization, and tracks design evolutions.

Modernizing Your CAD: 7 Criteria to Consider

Find the best CAD software for your engineering & design teams.

Explore More

Become a sheet metal expert with this handpicked collection of Tech Tips and instructional videos.

Unfolding Sheet Metal Design from CAD Model to Fabrication

06.26.2024

Sheet metal design doesn’t have to be difficult. Learn about the essential CAD tools that can make or break your sheet metal designs.

Read Blog

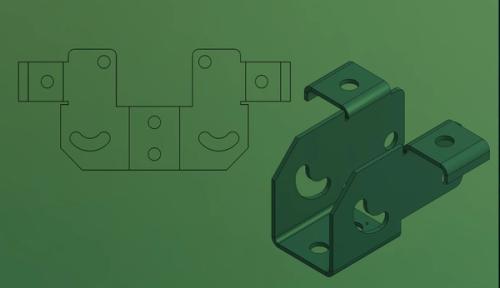

Sheet Metal Parts Designed for Manufacturing

04.23.2025

Two views, one design. Onshape’s sheet metal tools make it easy to work with your design in both flattened and formed states.

Read Blog

Tech Tip: Break Corners on Sheet Metal Parts in Onshape

12.03.2024

Learn how to break the sharp corners of your sheet metal parts using the Corner Break feature within Onshape.

Read Tech Tip

Tech Tip: How to Create a Custom Sheet Metal Forming Tool in Onshape

02.11.2025

Learn how to use and create a custom sheet metal forming tool in Onshape that streamlines design, enhances manufacturing accuracy, and ensures consistency with shared tool libraries.

Read Tech Tip

Tech Tip: How to Rename a Sheet Metal Context

01.02.2024

In this Onshape Tech Tip, learn how to rename a sheet metal context in the Sheet metal table and flat view.

Read Tech Tip

Tech Tip: How to Use DXF Files to Create a Sheet Metal Model in Onshape

05.21.2024

This Tech Tip explains how to use a DXF file to recreate a parametric sheet metal model using the Bend feature in Onshape.

Read Tech Tip

Designing for Sheet Metal Fabrication with CAD Software

09.10.2024

Learn how Onshape’s Sheet Metal software streamlines metal fabrication with real-time updates, reducing errors and improving efficiency in the design and manufacturing process.

Read Blog