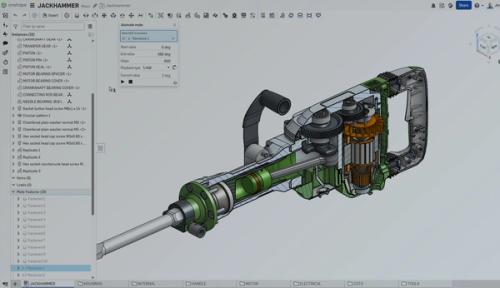

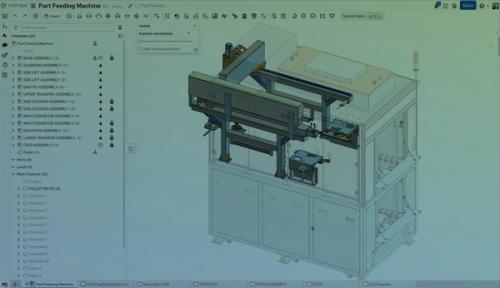

Onshape Assemblies

Quickly create detailed assemblies with efficient mates, standardized hardware, top-down design, assembly motion, and much more.

Quickly create detailed assemblies with efficient mates, standardized hardware, top-down design, assembly motion, and much more.

What are CAD assemblies?

A CAD assembly is a digital model that represents a complex product or system in a virtual environment. Often comprised of individual parts and sub-assemblies with specifications of their own, these assemblies are essential in mechanical design. They enable engineers to simulate and analyze the functionality, fit, and movement of a product, ensuring precise control over dimensions, materials, and relationships between components. This facilitates procurement, analysis, and much more, helping move the process from concept to manufacturing.

Key Features

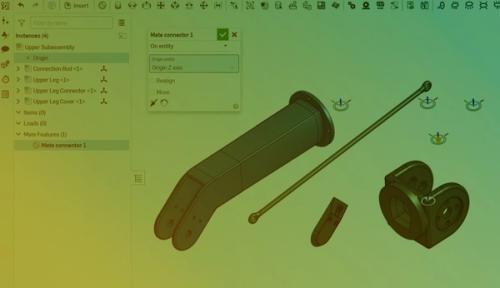

Advanced Mating Features

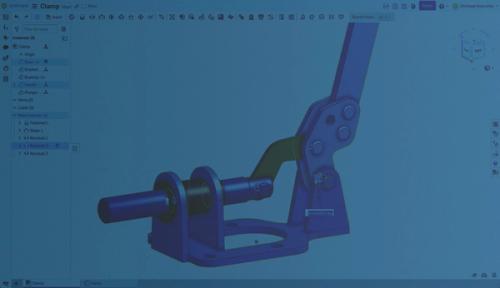

Onshape's mates streamline assembly creation by allowing high-level kinematic relationships, reducing build time and fragility. Users can define precise positioning, offsets, limits, and pattern parts based on distance and/or shape recognition. Then use gear, screw, rack-and-pinion, and other relationships to properly represent coupled motion.

Integrated Standard Content

Onshape transforms the tedium of hardware insertion with its innovative approach; the built-in library is accessible to all users, and streamlines the insertion process by auto-sizing fasteners to fit, and positioning them accurately. Enhance BOMs with company-specific metadata for fasteners. Then modify fastener stacks on the fly; while auto-adjusting for new additions, ensuring accurate assembly management.

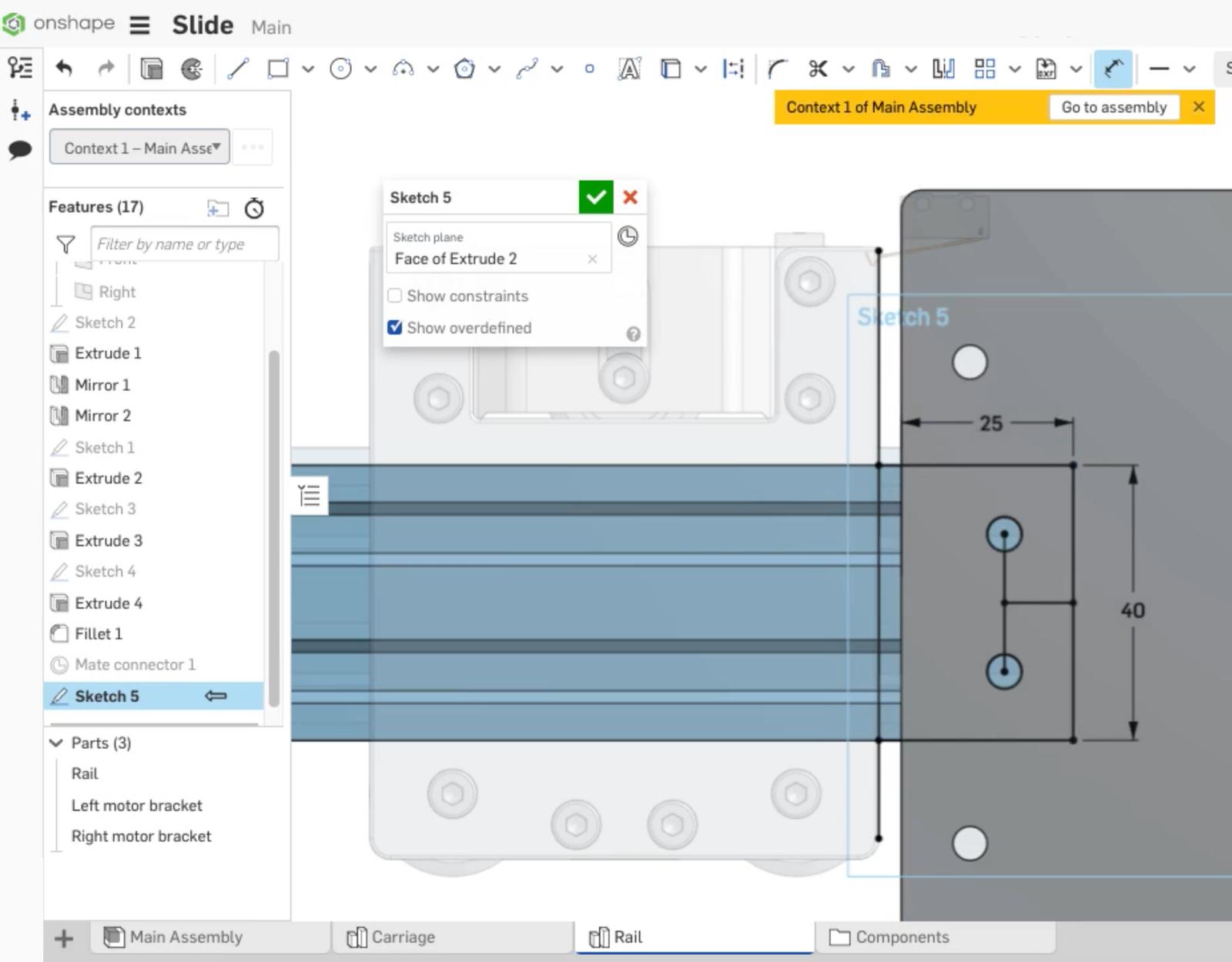

In-Context Design

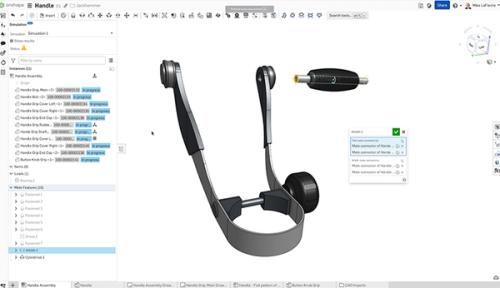

Experience Onshape's innovative in-context design, where you can create parts within assemblies, capturing snapshots for reference. It ensures perfect fit and clearances by allowing moving parts to reference others dynamically. With a robust reference system, updates are seamless and predictable, eliminating lost or broken links.

Explore More

Start your project off right with this curated selection of assembly-focused Tech Tips and instructional videos.

Build Assemblies Faster in Onshape

05.21.2025

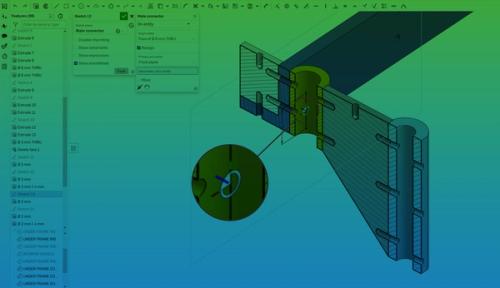

Onshape's mate system uses Mate Connectors to build assemblies with fewer constraints than traditional CAD tools, saving time while maintaining precise control.

Read Blog

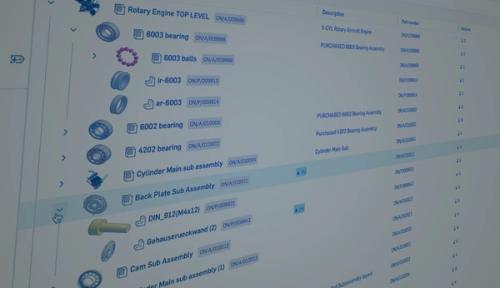

Gain Better Visibility with Product Structure View

09.23.2024

Onshape’s Product Structure View provides a clear and organized breakdown of released design components and their references directly from the documents page.

Read Blog

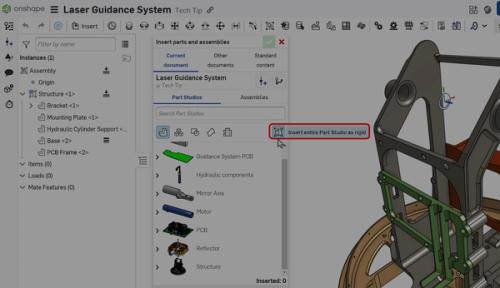

Tech Tip: How to Maintain Part Studio Integrity in Assemblies

04.16.2024

Learn how to effectively maintain Part Studio integrity in an Onshape Assembly, ensuring seamless synchronization throughout the design process.

Read Tech Tip

Tech Tip: How to Mate at the Origin Using Mate Connectors Instead of Planes

06.25.2024

Use Onshape Mate connectors to efficiently mate to the Part Studio or Assembly instance origins instead of using origin planes as reference geometry.

Read Tech Tip

Tech Tip: How to Position Parts Based on Mate Values

05.14.2024

In this Onshape Tech Tip, learn how to position parts based on mate values in your assemblies.

Read Tech Tip

Tech Tip: How to Use Mate Connectors On-the-Fly for Sketch Planes

06.11.2024

Mate Connectors are powerful for building assemblies and useful in Part Studios for defining reference geometry. They can create sketch planes without unnecessary construction geometry. Learn more in this Tech Tip.

Read Tech Tip

Tech Tip: How to Use the Pin Slot and Tangent Mate for Complex Sliding Motion

10.01.2024

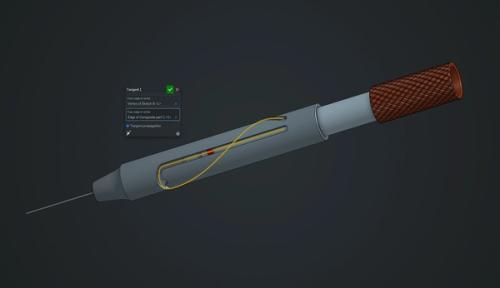

This Tech Tip demonstrates how to use the Pin Slot and Tangent Mate for creating complex sliding motions, featuring a workflow where a sliding mechanism follows a 3D curve.

Read Tech Tip

Tech Tip: Quickly Center Parts Using the Width Mate

06.17.2025

Learn how to use Onshape’s Width mate for precise CAD part centering and symmetric placement in assemblies.

Read Tech Tip

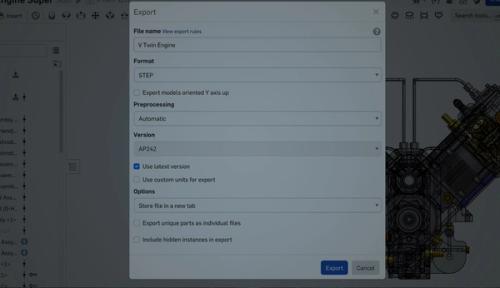

Tech Tip: Scoping Your Onshape Export Using Display States

11.26.2024

This Tech Tip will help you learn how to scope the export of an assembly by hiding components.

Read Tech Tip

Top-Down Design with Onshape: Master Complexity and Speed-Up Your Go-to-Market

04.30.2025

Unlock top-down design with Onshape's cloud-native CAD platform and 7 key tools that transform complex assembly management without the broken links of traditional systems.

Read Blog

Learn how easy making Assemblies in Onshape can be

Onshape’s built-in version control saves us considerable time, but more than anything, it just gives us peace of mind.’’