3:33

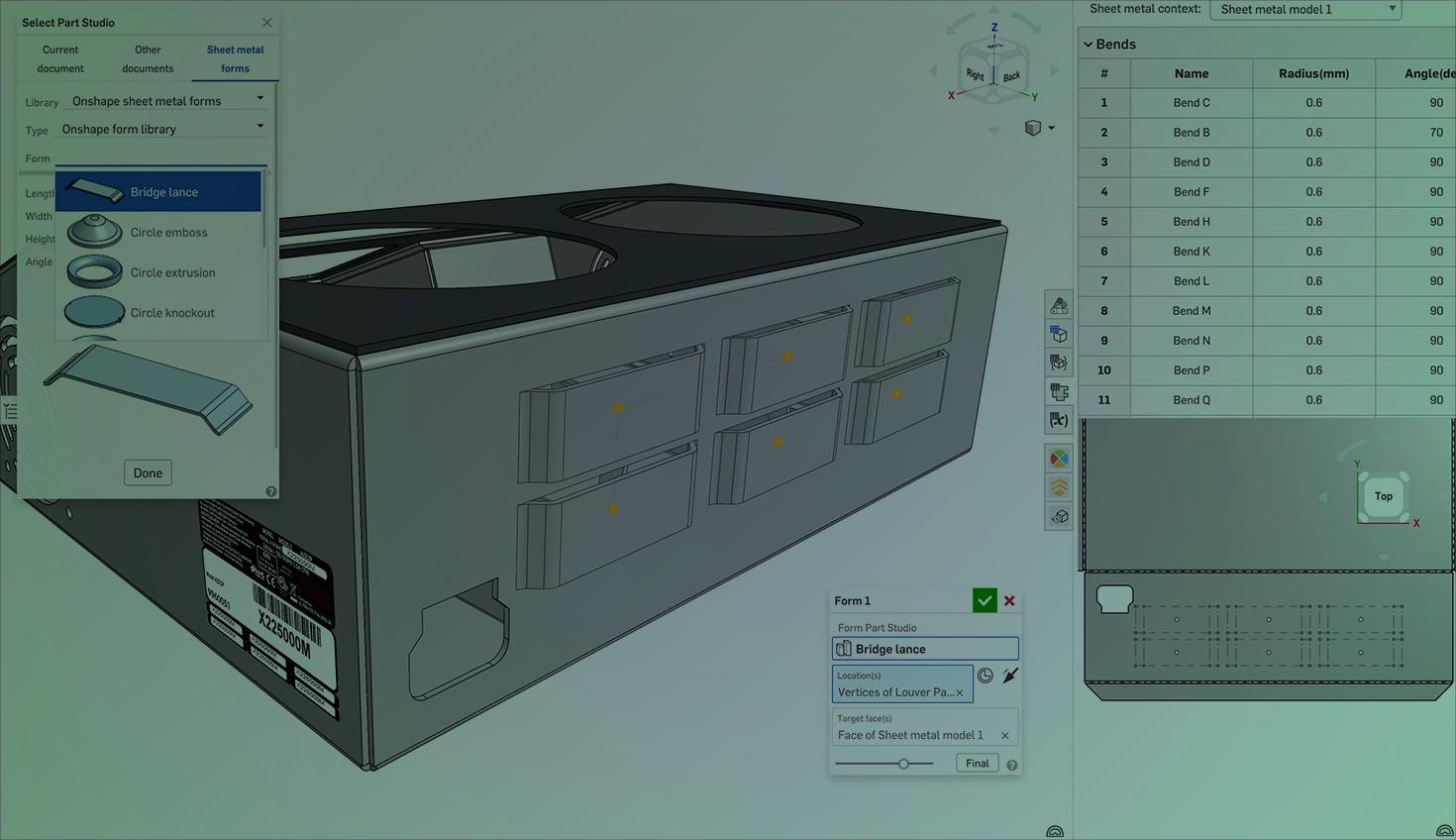

Onshape's sheet metal tools now includes a Form feature, also known as a forming tool, allowing you to quickly add stamped, embossed, or punched details to your sheet metal models.

Using Standard Sheet Metal Forms

A library of standard forms is included, each configured to let you specify the exact size needed to match your available tooling.

- Simply modify the parameters if necessary, then specify a location using either a sketch vertex or mate connector.

- Patterning is supported by way of a single sketch with multiple vertices, which is often the easiest way to apply multiple forms, similar to how the Hole feature works.

- The orientation of the form is based on the sketch plane or the Z-axis of the mate connector, and can be flipped, rotated, or offset as needed.

- Common form features such as louvers for ventilation and mounting bosses are readily available.

With just a few clicks, complex form geometry can be added to your sheet metal models with ease.

Watch the video below showing the use of an existing form tool from the Onshape sheet metal forms library.

Sheet Metal Forming Feature Behavior in Onshape

- The form feature geometry can be simple or complex, and it can pierce the sheet thickness or leave the material intact.

- For example, in a knockout or half-shear, the material is not completely punched through.

- A section view clearly shows the results of the deformation.

- In the flat pattern, Form features are displayed as sketches, ensuring visibility in both drawings and DXF exports.

A key benefit of Form features in Onshape is that you do not need to “finish” the sheet metal model before adding forms. Additionally, DXF outputs include the form tool profile and punch center, ensuring that manufacturing details are properly documented.

Creating Your Own Custom Sheet Metal Forms

You can also create custom form tools, such as vent patterns specific to your company, that may or may not deform the material. A form tool can also be used as a punch to fully remove material.

To create a custom form library, follow these steps:

- Create a folder for your form library and add at least one document.

- Each Part Studio tab in a document represents a single form tool, containing:

- A part that adds material

- A part that removes material

- Note: Your form tool does not have to have both parts. For example, if you only want to remove material from the sheet metal, create one part to subtract material from it.

- Include a Length configuration variable named thickness, and use it to drive sketches and geometry. The thickness FeatureScript ID is used to drive the form thickness from the Sheet metal model feature's Thickness value.

- This enables the same form to be used across different sheet metal thicknesses.

Managing Custom Form Libraries

The updated Tag feature used for frame profiles now extends to forms.

- Select the part to add, the part to remove, and the sketch to appear on the flat pattern.

- By default, the origin of the Part Studio is used, but a mate connector can define the origin and orientation if needed.

Once your form is finalized:

- Version the document so it can be linked.

- Go to the library folder, right-click, and choose Set Library > My Sheet Metal Forms.

- Company Admins can share the library with the entire company, making the tools accessible to all users.

Now, when editing a sheet metal part, your custom forms are available without needing to navigate to the document manually.

Watch the video below to learn more about the custom form tool and Library Management.

Exporting Form Features in DXF

When exporting a DXF file, two new options ensure form features are clearly represented for manufacturing:

- Include Form Feature Outlines

- Include Form Feature Center Marks

The video below tackles this topic.

Why Use Form Features in Onshape?

- Quickly apply standard manufacturing features without manual modeling.

- Ensure design consistency across projects with shared libraries.

- Generate accurate manufacturing documentation with Form feature outlines and center marks in DXF exports.

Onshape’s Form feature provides a flexible and accurate approach to sheet metal design, making it easier to create realistic, manufacturable features that match production processes.

Interested in learning more Onshape Tech Tips? You can review the most recent technical blogs here.

Onshape on YouTube

Subscribe to our channel to stay up-to-date on new product releases, Onshape Tech Tips, and more!

Latest Content

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more