02:58

Onshape by PTC just announced the beta release of its CAD/CAM integration.

CAM Studio integrates seamlessly with Onshape’s cloud-based Computer-Aided Design (CAD) platform, which includes built-in Product Data Management (PDM), offering a holistic and collaborative approach to the design-to-manufacturing workflow.

With all the design and manufacturing data stored in the cloud, users can access it from anywhere, easily share updates, and eliminate the hassles of file version conflicts. This is especially advantageous for machinists who need the most up-to-date models on the shop floor and for engineers who need quick feedback on design for manufacturing (DFM).

Key Features:

- Cloud-Based Workflow: Access and collaborate from any browser with an internet connection.

- Integrated CAD/CAM: Make seamless design-to-manufacturing transitions without switching platforms.

- Version Control: Reduce errors and lost hours by using a single source of truth for your models.

- Collaboration: Empower cross-functional teams to work on the same project simultaneously.

Benefits for Machinists

- Increased Productivity: By keeping design and manufacturing in sync, machinists spend less time managing file versions and more time producing parts.

- Collaboration & Transparency: Whether multiple operators are working on the same machine or design engineers are making last-minute tweaks, Onshape CAM Studio keeps everyone aligned with a single, cloud-based source of truth.

- Enhanced Process Control: Simulations minimize the risk of errors on the shop floor. You can verify toolpaths, detect collisions, and optimize speeds before cutting material.

Benefits for Engineers

- Reduced Communication Barriers: With the entire team using the same platform, engineers can collaborate seamlessly with production staff, clarifying design intent, and minimizing rework.

- Streamlined Version Control: Version control makes it easy to manage and compare different iterations of a design, so engineers can refine parts without confusion.

- Faster Iteration Cycles: Engineers can quickly test design ideas with machinists able to give real-time feedback, make modifications, and see how those changes affect machining in a single environment.

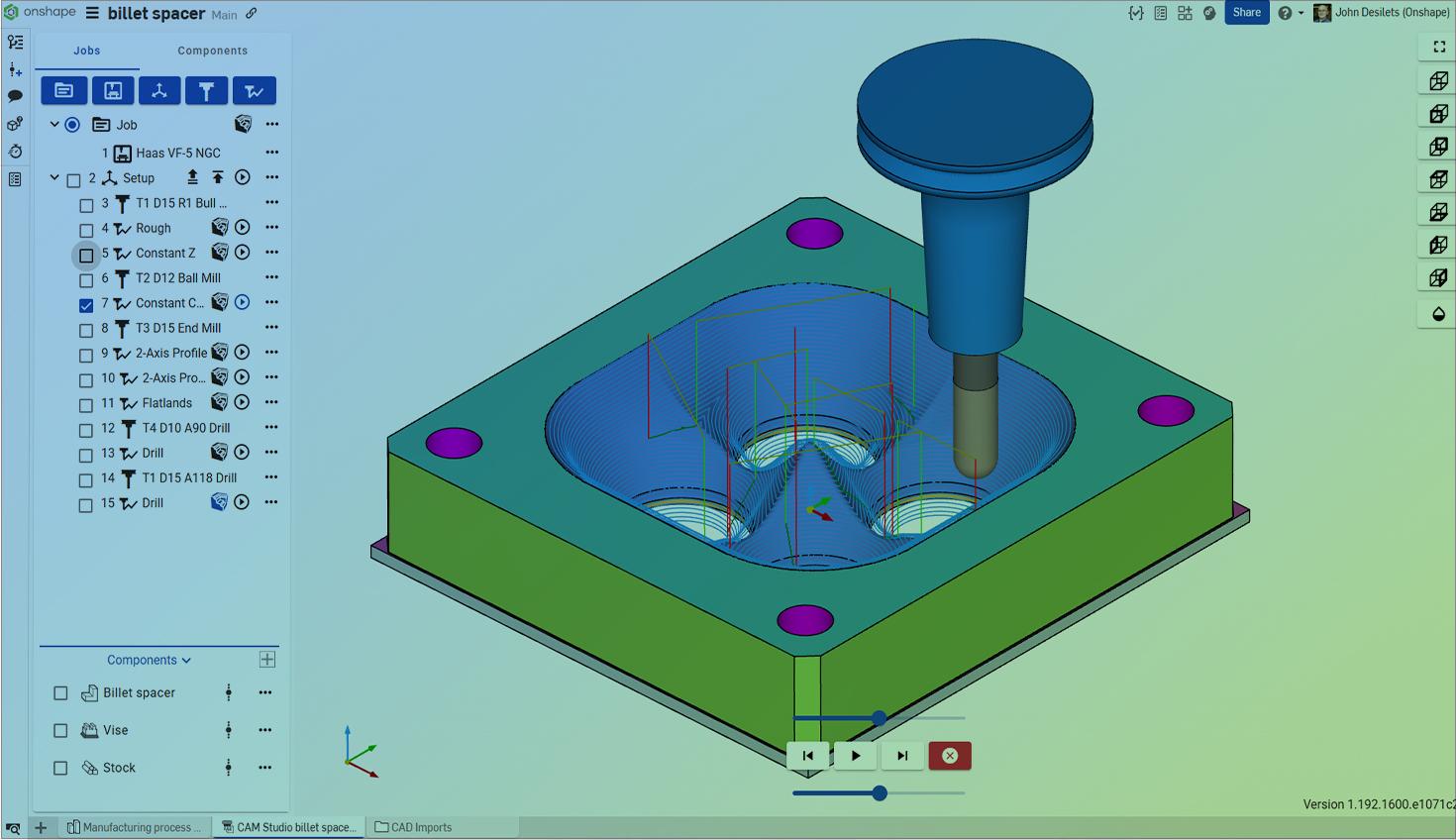

Onshape CAM Studio Workflow

A typical workflow for engineers and machinists using Onshape CAM Studio is streamlined. For example:

- Design in Onshape: Start by creating their part model in Onshape. Leverage parametric design tools to build 3D geometry.

- Define CAM Setup: Referencing the CAD model, choosing their machine type, coordinate system, and generating stock dimensions.

- Create Toolpaths: Generate milling operations, select cutters, set speeds/feeds, and define cutting strategies.

- Simulate: Validate processes by simulating toolpaths. Identify any potential collisions or tooling issues before production.

- Generate G-Code: Once satisfied, generate the G-Code and send it directly to the CNC equipment.

- Production: Execute G-Code on the CNC machine to produce the final part.

Comparing Onshape CAM Studio

Feature | Onshape CAM Studio | Fusion | SOLIDWORKS |

Cloud-Based | ✔ 100% Cloud-Native | ✖ CAD/CAM Applications Install Locally | ✖ Local Install |

Hardware Requirements | ✔ Runs in Any Browser | ✖ Requires a Workstation | ✖ Requires Workstation |

Cloud HPC for Simulation and Collision Detection | ✔ Included | ✖ CAM Simulations Run Locally (Limited Compute and Multi-Threading) | ✖ All Simulations Run Locally (Limited Compute and Multi-Threading) |

Software Maintenance & Updates | ✔ New Features Every Three Weeks | ✖ Automatic Updates to Locally Installed Applications (Can Lead to Unstable Applications) | ✖ Manual Upgrades |

Built-in PDM Integration | ✔ Included | ✖ (File-Based) Requires Manage Extension | ✖ (File-Based) Requires SOLIDWORKS PDM |

Collaboration | ✔ Included | ✔ Requires Manage Extension | ✖ No |

Storage & Access Control | ✔ Cloud Encryption Included | ✔ Requires Manage Extension | ✖ Local Storage Risks |

Multi-Axis Support | ✔ Up to 3-Axis Included ✔ Up to 5-Axis (Available on Request with CAM Studio Advanced) | ✔ Up to 3+2 Positional is Included ✔ Up to 5-Axis (Requires Manufacturing Extension) | ✔ Basic 2.5-axis milling ✔ Up to 5-axis (Requires CAMWorks Milling Professional/Premium) |

Feature

Onshape CAM Studio

Fusion

SOLIDWORKS

Cloud-Based

✔ 100% Cloud-Native

✖ CAD/CAM Applications Install Locally

✖ Local Install

Hardware Requirements

✔ Runs in Any Browser

✖ Requires a Workstation

✖ Requires Workstation

Cloud HPC for Simulation and Collision Detection

✔ Included

✖ CAM Simulations Run Locally (Limited Compute and Multi-Threading)

✖ All Simulations Run Locally (Limited Compute and Multi-Threading)

Software Maintenance & Updates

✔ New Features Every Three Weeks

✖ Automatic Updates to Locally Installed Applications (Can Lead to Unstable Applications)

✖ Manual Upgrades

Built-in PDM Integration

✔ Included

✖ (File-Based) Requires Manage Extension

✖ (File-Based) Requires SOLIDWORKS PDM

Collaboration

✔ Included

✔ Requires Manage Extension

✖ No

Storage & Access Control

✔ Cloud Encryption Included

✔ Requires Manage Extension

✖ Local Storage Risks

Multi-Axis Support

✔ Up to 3-Axis Included

✔ Up to 5-Axis (Available on Request with CAM Studio Advanced)

✔ Up to 3+2 Positional is Included

✔ Up to 5-Axis (Requires Manufacturing Extension)

✔ Basic 2.5-axis milling

✔ Up to 5-axis (Requires CAMWorks Milling Professional/Premium)

Bridging the Gap Between Design and Production

Onshape now offers a holistic solution for machined parts design and manufacture. It empowers teams to focus on innovation rather than struggle with the mundane details of file-based systems.

By bridging the gap between design and production, Onshape CAM Studio creates a truly collaborative ecosystem where engineers can experiment freely, and machinists can execute with confidence. The result is a streamlined, cost-effective process that delivers higher-quality products in less time.

Ready to give it a try?

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Industrial Equipment & Machine Design

Reframe Systems: Transforming Homebuilding with Digital Automation and Cloud-Native Onshape

09.25.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more