2:43

At World Bicycle Relief (WBR), innovation is at the heart of our mission to provide mobility solutions that withstand the toughest conditions. The Buffalo Bicycle is more than just a mode of transport – it’s a lifeline for students, healthcare workers, and entrepreneurs in rural regions.

The Buffalo Bicycle enables mobility for entrepreneurs and workers in rural communities.

To ensure that every Buffalo Bicycle meets the highest standards of durability and reliability, our product development (PD) team is constantly refining and enhancing our designs based on direct feedback from the riders in the communities where we operate.

Guided by our motto that “all answers are found in the field,” we listen to those who rely on our bicycles daily, ensuring that every improvement addresses real-world challenges. Since 2019, Onshape by PTC has been one of the key tools supporting this ongoing innovation.

Advancing Buffalo Bicycle Development

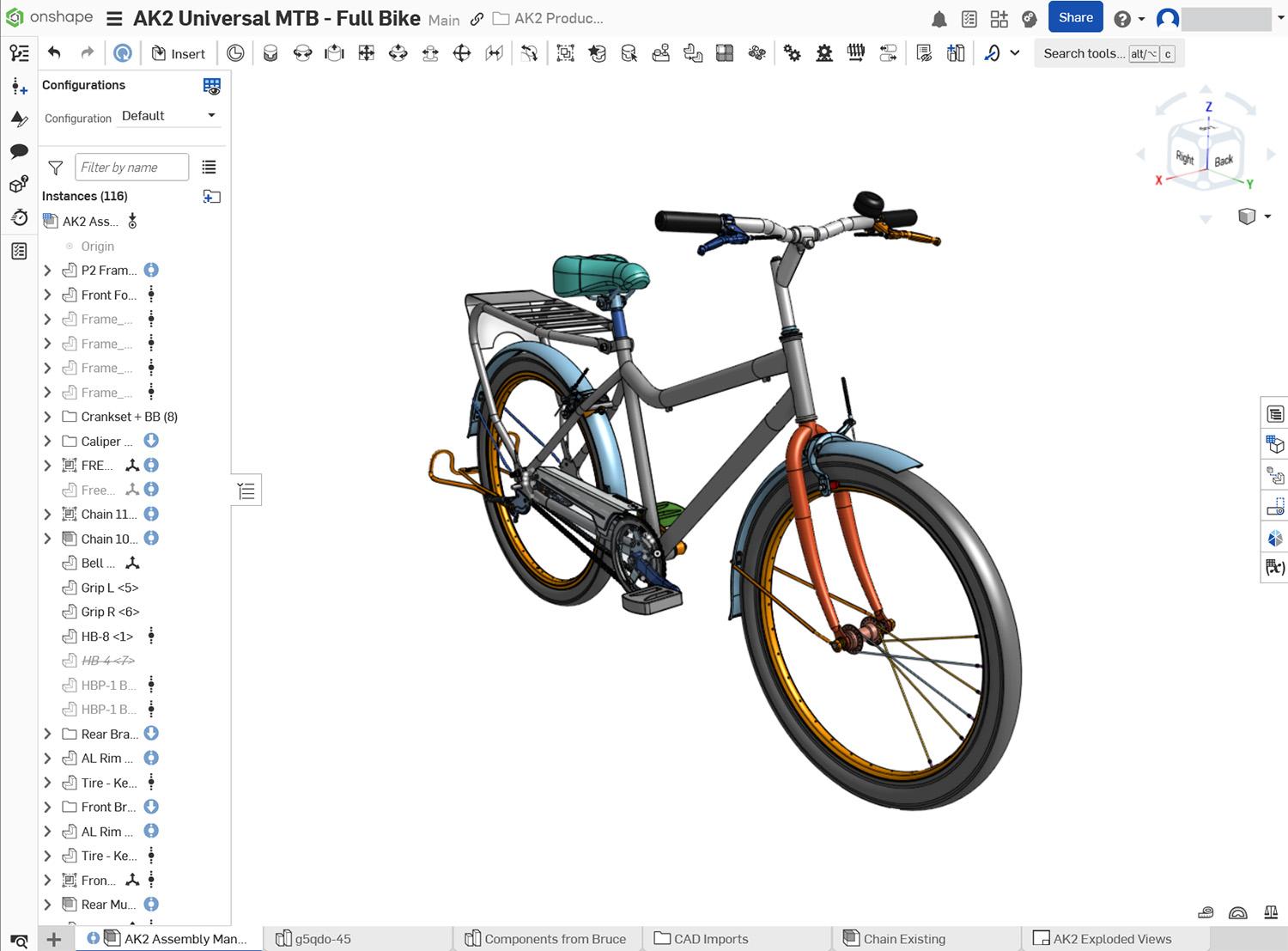

WBR develops their products in Onshape, using CAD to communicate with their global team.

As we deepened our commitment to optimizing the Buffalo for the real-world challenges our riders face, we saw the need for a more structured product development process. That’s when we turned to Onshape – a cloud-based CAD system that allowed our globally distributed engineering team to collaborate seamlessly.

With Onshape, we’ve been able to:

- Quickly iterate on new designs, ensuring they meet the rigorous demands of our riders.

- Access and modify technical drawings directly on the manufacturing floor, reducing errors and streamlining production.

- Simulate the full Buffalo Bicycle configuration to test the compatibility of new concepts with existing components.

- Keep product data organized and controlled, allowing for continuous improvements over time.

Innovations That Are Moving Us Forward

One of the most significant advancements powered by our refined design process is our proprietary drivetrain system, the AK2, introduced with the launch of the Buffalo Utility S2. This award-winning system was developed to improve durability and efficiency in the toughest riding conditions, and Onshape played a role in helping us fine-tune the design. More than just a new component, the AK2 is part of our broader effort to enhance the performance and lifespan of every Buffalo Bicycle.

Currently, over 45 new components and assemblies have been fully designed and controlled within our system, and we continue to integrate legacy parts into this structured process. This approach is helping us future-proof our bicycles, ensuring that each new design is not only built to last but also easy to service and upgrade.

The Buffalo Bicycle will continue to get stronger and more efficient, to tackle the real world needs of its users.

The Future of Buffalo Bicycle Innovation

The improvements we make today will have a lasting impact on the people who rely on our bicycles. From longer-lasting drivetrain components to optimized frame geometry, every decision we make is focused on making the Buffalo stronger, more efficient, and better suited for real-world needs.

As we continue to refine our processes and explore new solutions, we remain committed to using the best tools available to support our mission. The Buffalo Bicycle has come a long way, but there’s always more work to be done. By driving continuous innovation, we ensure that our bicycles remain a powerful force for mobility, resilience, and opportunity for generations to come.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Automotive & Transportation

Zero Crashes, Limitless Collaboration, One Connected Workflow With Cloud-Native Onshape

12.04.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more