Just because a future product looks fabulous as a CAD model is no guarantee it will work exactly the way you expect it to.

Informal, an international freelance network that connects engineering and manufacturing professionals with companies needing to augment their current teams, experiences this product design truth with every project.

When designing the Neurosity Crown, “the world’s first wearable brain computer,” the Informal engineering team used additive manufacturing to print multiple plastic prototypes to adjust the ergonomic fit and positioning on the head. The 3D-printed parts were also used to determine the best placement for electrodes. The Crown, which gives off a stylish science-fiction vibe, is a headset that promises to “boost your brain’s concentration by measuring your brain waves and playing music that increases your focus.”

Naturally, people have different-sized heads and it took several iterations to get everything lined up correctly.

After redesigning the Neurosity Crown’s parts for more scalable, additive manufacturing processes, the Informal engineers could then create prototypes with more expensive Urethane casting and later injection molding. Using inexpensive plastic printing in the earlier stages speeds up the prototyping process considerably compared to traditional manufacturing methods.

“If I have an error in an injection-molded plastic part, it can take between three weeks and a month and a half to fix the issue in the molds,” notes mechanical engineer and Informal co-founder Sam Holland. “But if I have 3D-printed parts prior to that and assemble them, I can catch the problem within a day or two. So every issue you find with the 3D prints could theoretically save you a month of time later on.”

Holland adds that making quick plastic 3D prints of his projects also helps him rethink his CAD models in the earliest stages.

“Sometimes it's hard to remember the scale of what I'm working on. I might be deep in a 3D model, and when I get it back from the printer, I’m surprised to see the part is too tiny or too big. It's really difficult to get that sense of scale without 3D printing something and touching it,” he says.

“When you’re looking at your CAD model, even an infinite number of section views won't show you that a part is interfering in a certain way or sliding a certain way. Sometimes there is no substitute for just building your parts and testing them.”

Cloud-Native CAD Streamlines Collaboration

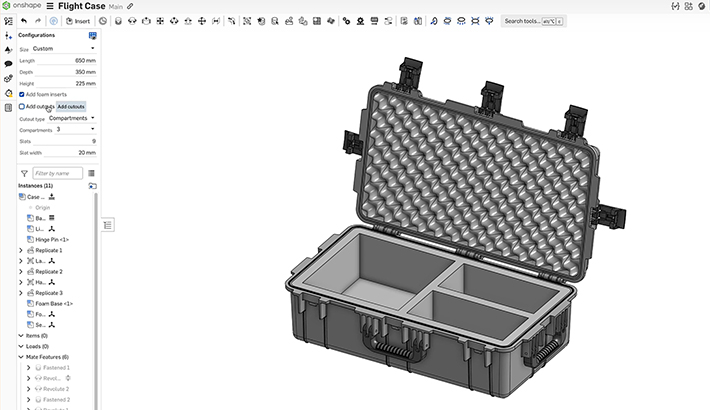

To build the Neurosity Crown, “the world’s first wearable brain computer,” Informal engineers relied on cloud-native Onshape, which enables product development partners to see real-time design changes and create prototypes more quickly.

To streamline communication with its clients, Informal uses Onshape, the only cloud-native product development platform to combine a robust CAD system with real-time data management and collaboration tools. Whenever one engineer makes a design change, everyone else on the team instantly sees it.

Also supporting asynchronous collaboration, a comprehensive edit history tracks who made what changes and when, and also allows teams to immediately revert back to any prior state of the design.

“The most valuable aspect of using Onshape for collaboration is the ability to share view-only CAD models with clients to allow them to move and interrogate models on their own time,” says Holland. “We used to send screenshots or videos of the parts in CAD, but it is difficult sometimes to convey the design without allowing the customer to spin the model around for themselves.”

Introduce “Additive-First” and “Cloud-First” Strategies at Your Company

The rapid cycle of 3D printing prototypes, testing them, and incorporating feedback into the next iterations of CAD models is critical for speeding up product development. Want to learn more about how forward-thinking companies leverage additive manufacturing and cloud-native design tools?

Onshape’s new eBook, “Accelerating Product Development with 3D Printing and Cloud-Native CAD,” offers a fresh perspective on how your engineering and manufacturing teams can use these disruptive technologies more effectively together.

Download your free copy today to explore “Additive-First” and “Cloud-First” strategies for transforming your organization!

Accelerating Product Development eBook

Learn how to better implement additive manufacturing & cloud-native product development.