06:22

Organizations reliant on legacy CAD drawing software often underestimate the profound inefficiencies that emerge during the critical handoff to manufacturing. Outdated methodologies not only generate bottlenecks but also amplify the risk of miscommunications and costly errors, which can ripple through production schedules and inflate operational costs. These challenges are exacerbated by disconnected systems that fail to provide real-time updates, leaving teams to grapple with outdated files and manual processes.

Modernizing these workflows offers a powerful opportunity to reimagine the transition from design to manufacturing. By embracing cloud-native platforms and advanced collaboration tools, such as PTC’s modern CAD software Onshape, organizations can eliminate redundancies, maintain design fidelity, and foster a seamless exchange of information. These innovations not only enhance accuracy and reduce delays but also empower teams to scale their operations and remain agile in the face of evolving industry demands.

This blog explores five transformative Onshape capabilities specifically designed to optimize the handoff of engineering designs to manufacturing teams or external partners. With detailed insights and implementation tips, it also serves as a framework for addressing the most pressing challenges in the handoff to manufacturing.

1. Convey Complex Designs with Enhanced Contextual Clarity

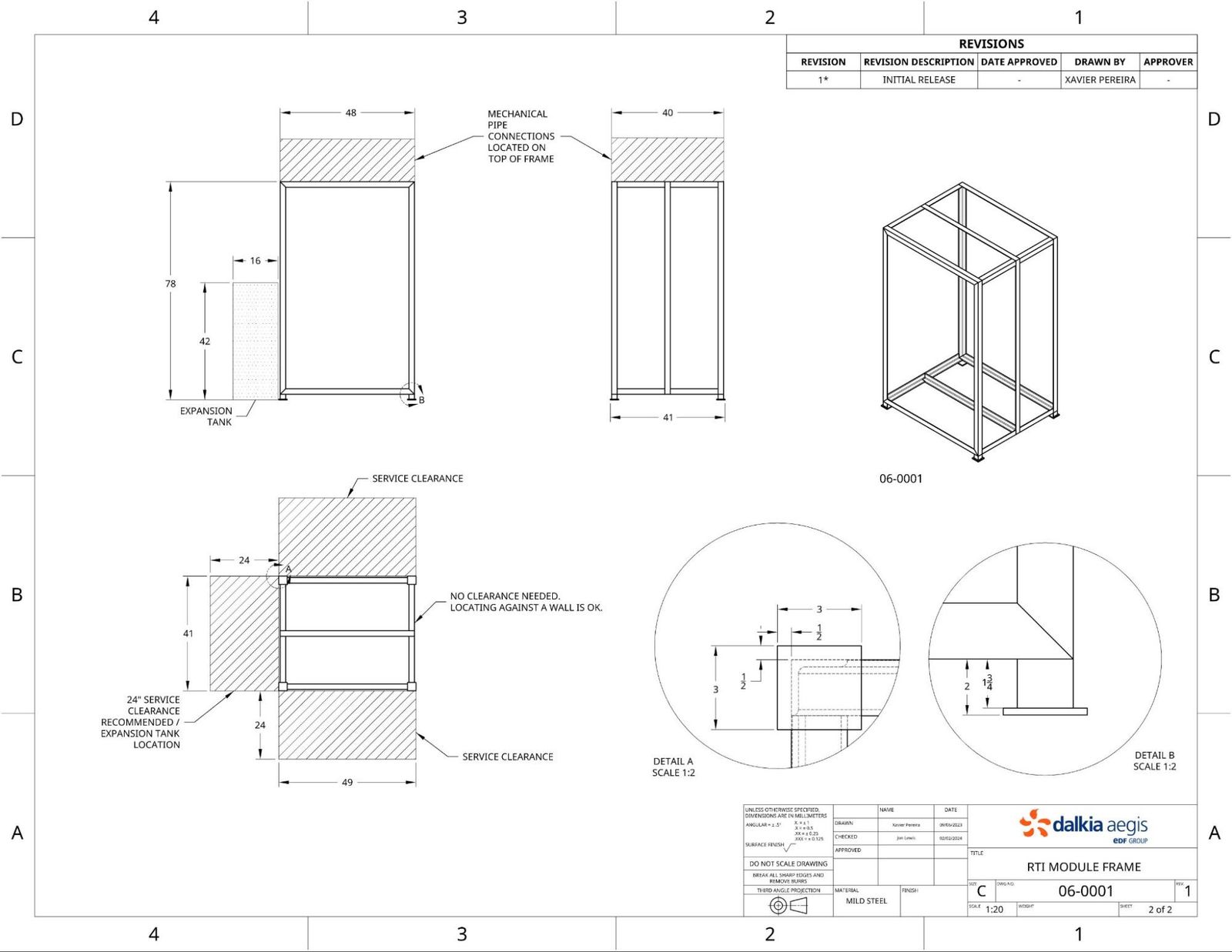

Onshape supports the creation of production-ready drawings featuring multiple views, precise annotations, and adherence to rigorous industry standards, including ANSI, ISO 16792/5459, and GD&T frameworks. These capabilities ensure manufacturing documentation is not only accurate but also tailored to specific production requirements, such as geometric tolerances and surface finishes. By delivering highly detailed and context-rich representations, engineers can bridge the communication gap between design and manufacturing, eliminating ambiguity, minimizing errors, and accelerating the production process.

What to Try: Explore Onshape’s Drawings Tech Tips and create a detailed Drawing with geometric dimensions, tolerances, surface finishes, and fastener locations. Try adding tables, callouts, balloons, and other standard elements.

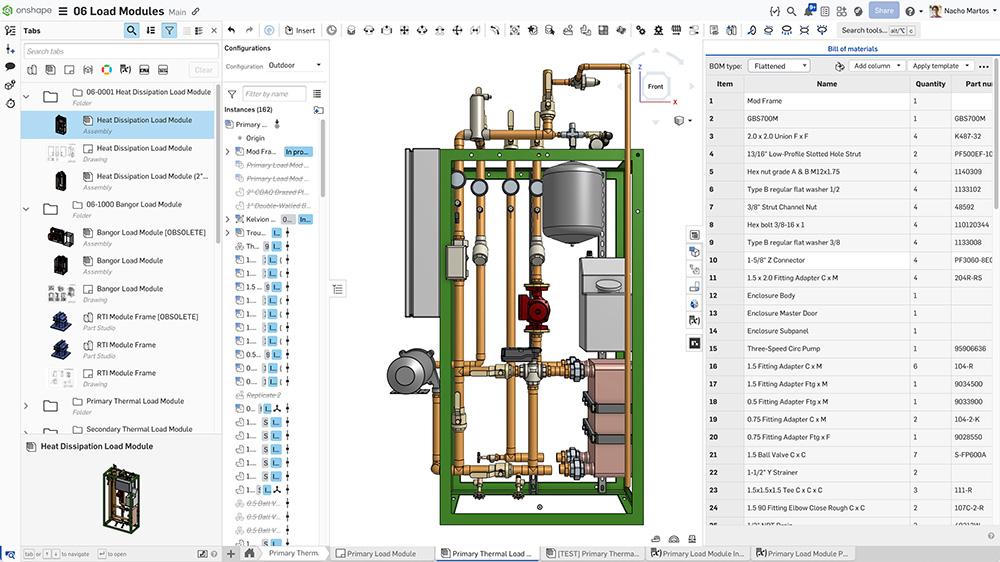

2. Benefit from Integrated Data Management

Onshape’s integrated data management system (PDM) redefines the design-to-manufacturing handoff by centralizing CAD models, assemblies, and Drawings within a single, cloud-native platform. This seamless integration ensures that all design data – from 2D sketch to 3D model edits – is automatically synchronized, maintaining consistent alignment across BOM tables, linked documentation, and associated elements. By integrating product data management directly into the design process, Onshape eliminates reliance on external PDM systems and file dependencies, significantly reducing errors and ensuring that manufacturing teams receive accurate, up-to-date information.

What to Try: Create changes in a part or assembly and track those changes through to a Drawing. Notice anything? With Onshape, there are no files and no broken assembly references! All information flows from the CAD model into the Drawing, from dimensions to decals.

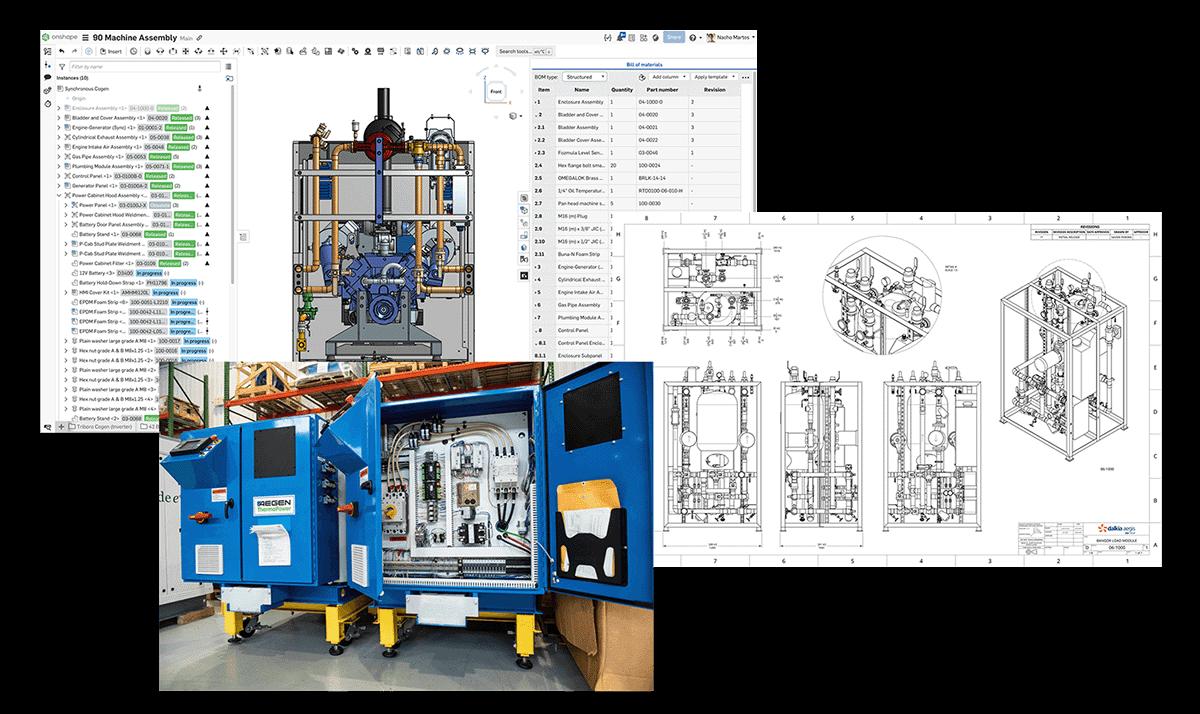

3. Streamline Design Releases

With built-in PDM functionality, Onshape transforms the versioning and release processes by consolidating all referenced components within a Drawing into a cohesive, automated workflow. This functionality eradicates the inefficiencies of managing disconnected files and ensures that design intent is meticulously preserved, maintaining alignment between engineering and manufacturing teams. Real-time revision tracking allows teams to effortlessly monitor updates, generate comprehensive audit trails, and synchronize changes instantly, significantly reducing errors and miscommunication.

Additionally, Onshape’s robust automation capabilities streamline repetitive administrative tasks, enabling teams to focus on high-value activities such as refining designs and solving complex engineering challenges. By simplifying release management, Onshape ensures that all stakeholders, from design engineers to manufacturing teams, are equipped with the most up-to-date information. This seamless integration fosters stronger collaboration, accelerates the handoff process, and ultimately shortens production timelines. Teams leveraging Onshape’s PDM features can expect greater operational efficiency, improved accuracy, and a transformative approach to bridging the gap between design and manufacturing.

What to Try: Enable Onshape’s out-of-the-box release management workflow, assign reviewers, and create a release candidate off of a Drawing. Bonus points if you set up mobile notifications and approve the Drawing using Onshape’s mobile app. You may want to consider inviting a colleague to the trial and assign them as a reviewer in your release process.

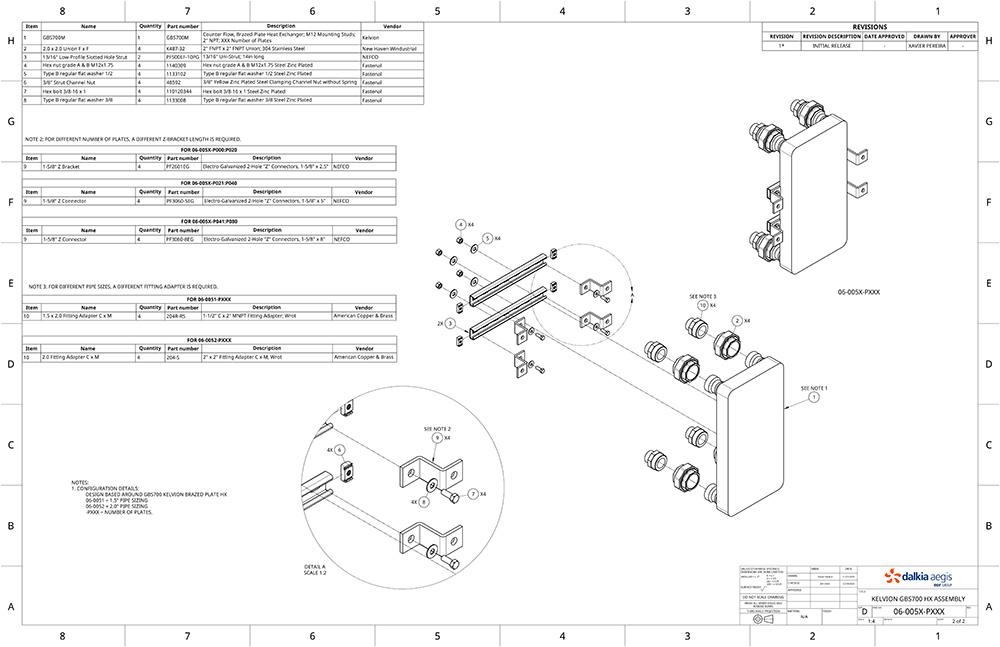

4. Enhance Communication with Manufacturing Teams

Onshape provides comprehensive support for a variety of tables crucial for manufacturing, including revision tables, inspection tables, hole tables, and cut-list tables, facilitating manufacturing and quality processes. Better yet, when you share a manufacturing partner into a design using the Publication feature, you can control exactly what version of the CAD data they see and access. This means you can clearly communicate your manufacturing and inspection instructions with the context of your full 3D model.

What to Try: Create a table within a Drawing, share a manufacturing partner into the Document, and tag them with a comment. With Onshape, you can treat your manufacturing partners as close collaborators and provide access to your design data to extended team members.

5. Create and Share CAD Drawings Seamlessly Across Platforms

Onshape empowers users to generate, disseminate, and manage Drawings from any web-enabled device, offering unparalleled flexibility to operate effectively from home, the office, or directly on the shop floor. This functionality ensures engineering teams remain agile and responsive, regardless of physical location or environmental constraints. By enabling immediate access to up-to-date Drawings, Onshape eliminates delays caused by version control issues or restricted file access, ensuring seamless project continuity.

With its cloud-native capabilities, Onshape removes traditional barriers to collaboration, such as fragmented workflows or reliance on local servers. Teams can work concurrently, share insights in real-time, and leverage an intuitive interface to accelerate iterations. This integration not only enhances productivity but also reduces the time required to address design challenges, ultimately paving the way for superior project outcomes and streamlined manufacturing handoffs.

What to Try: Work where you want to work by accessing your CAD drawings from any device, including Onshape’s mobile app for iOS and Android. You can download the apps for free from the Apple App Store or Google Play.

An Integrated CAD and PDM Experience

By integrating CAD and PDM capabilities into the design-to-manufacturing handoff, teams can streamline workflows, ensure precise alignment between design and production, and expedite product development timelines. These strategies address common inefficiencies of legacy CAD drawing software, foster seamless collaboration, and safeguard the integrity of design intent from concept through production.

Organizations leveraging these approaches are better equipped to overcome modern manufacturing challenges, achieving superior results with enhanced precision and operational efficiency.

Reduce Time to Market with Onshape

Dalkia digitized its product development and handoff to manufacturing with Onshape, reducing time to market by 25% to 50%.

Latest Content

- Case Study

- Automotive & Transportation

Zero Crashes, Limitless Collaboration, One Connected Workflow With Cloud-Native Onshape

12.04.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more