05:25

Most startups want their flagship products to make a lot of noise in the market. The team at Liftero will be happy when their products make no noise at all.

That will mean they have succeeded.

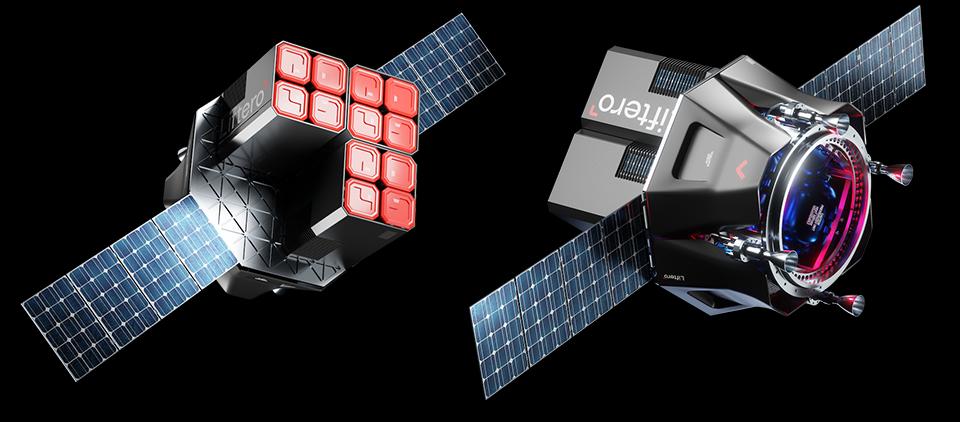

There is no sound in space, and that’s where they hope their reusable orbital transfer vehicles will be the go-to transportation for satellites reaching their final destination. After decades of slow progress, governments and companies are now rushing into space with satellites and other payloads. Space is the next open frontier, and Liftero wants to be there.

“The space market is growing rapidly because the cost of launching something into space has lowered in the last 20 years, and it’s still going down,” said Liftero co-founder Tomasz Palacz, who is also company CEO and CTO. “Our company wants to be right in the middle of that. We have the potential to transform space logistics and mobility.”

This video can best illustrate the Liftero vision. Courtesy Liftero.com

Aiming to Be a Big Player in the Space Race

Palacz and fellow co-founder and COO Przemyslaw Drozdz started Liftero in Krakow, Poland, in 2022 after working together at another space technology company. They each have master’s degrees in engineering, and Palacz earned a Ph.D. in space propulsion. Their work with the European Space Agency (ESA) and on EU-funded projects laid the foundation for what they want to achieve with Liftero.

They and their Liftero colleagues want to revolutionize orbital transportation. As of early 2024, there were about 9,500 satellites in space, with anywhere from 5,400 to 6,700 of them active. The last three years saw a particularly huge spike in satellite launches: nearly a 30-percent increase each year. Companies and governments have firm plans to continue placing satellites in space for communications, weather, military, and other purposes — and Liftero knows they will all need a ride once in space.

Liftero is developing reusable orbital transfer vehicles that would be able to take payloads from one point to another in space. Recycling rockets, satellites, and other equipment is a top focus of the aerospace industry. Using what is already in space increases value and reduces waste. Liftero’s orbital transfer vehicle, Motus, would be a reusable taxi, tugging satellites on the last miles of their journey.

The company is also making strides with its Whisper chemical propulsion system. Spacecraft have long relied on very toxic and difficult-to-handle fuel – hydrazine and nitrogen tetroxide. As the space industry becomes more commercial and sustainable, there is a push to move away from these toxic propellants, due to the high cost they add to satellite missions. Liftero’s propulsion system is “green,” using nitrous oxide and propane, a non-toxic, safe, and relatively cheaper fuel.

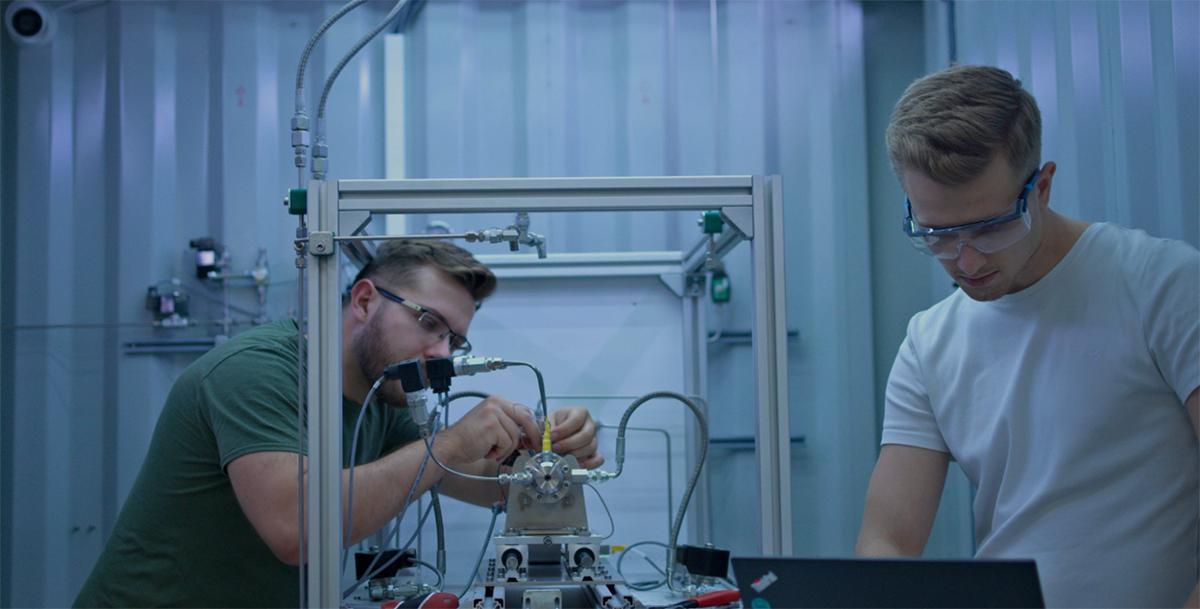

Whisper powers Motus, or it can be purchased as a standalone turnkey system that can be tailored to a customer’s mission specifications. The Liftero team is constantly testing products, like what's shown below, but the first big test is coming soon. Liftero recently signed a contract with a satellite provider that will use Whisper to propel and steer a satellite on its end-of-mile journey.

“That will be a huge milestone because then we’ll have our technology, our product, tested in space,” Palacz said. “It’s an opportunity to show other customers what we can do. This will be, I hope, a huge step for our company.”

Liftero Takes Advantage of CAD Software for Startups

You could say Liftero is flying high. Aside from that upcoming mission, the company secured funding from several investment firms and is part of an ESA business incubator program that puts them in touch with mentors and other resources.

“We’re proud of that,” Palacz said.

Yet, as much as the company has its eyes set on space, it has to keep its focus on Earth-bound endeavors, including designing its products using CAD software. Liftero first went with SOLIDWORKS because many employees had already used it. Still, the team soon felt constrained by the product because, Palacz said, of its version control system and how it limited collaboration.

“So we ran into making this very complex tracking system with our folders and spreadsheets,” he said. “This was very manual, and we really couldn’t track changes. We couldn’t view files at the same time.”

Liftero also got frustrated with SOLIDWORKS’ pricing system.

“Sometimes the price was this, and sometimes the price was that, and we couldn’t foresee what it would be next,” Palacz said. “Their strategy — I must say, it was not very nice — would be to offer a discount for a short amount of time, but at the same time, they said that they would raise prices soon.”

Palacz found a solution in a YouTube video about Onshape.

“From what I saw,” he said, “I immediately was interested because Onshape showed how it can help from a development perspective. There’s a focus on improving collaboration and version control when making changes.”

Liftero qualified for the Onshape Startup Program, an initiative that gives qualifying hardware startups access to Onshape Professional, a fully cloud-native CAD and PDM package with integrated simulation and rendering tools.

“It’s just what we needed,” Palacz said. “Collaboration and having access to CAD on the cloud is important, and we are getting more out of our Onshape CAD software because it’s so easy to work together.”

Palacz and his team also appreciate how Onshape is quick to make updates — and keep his team aware that updates are coming, something he said SOLIDWORKS didn’t do.

CAD Software that Lets Liftero Design and Develop Rapidly

Palacz and his team are over the moon about how they can rely on Onshape to be a key player in their rapid design and manufacturing process.

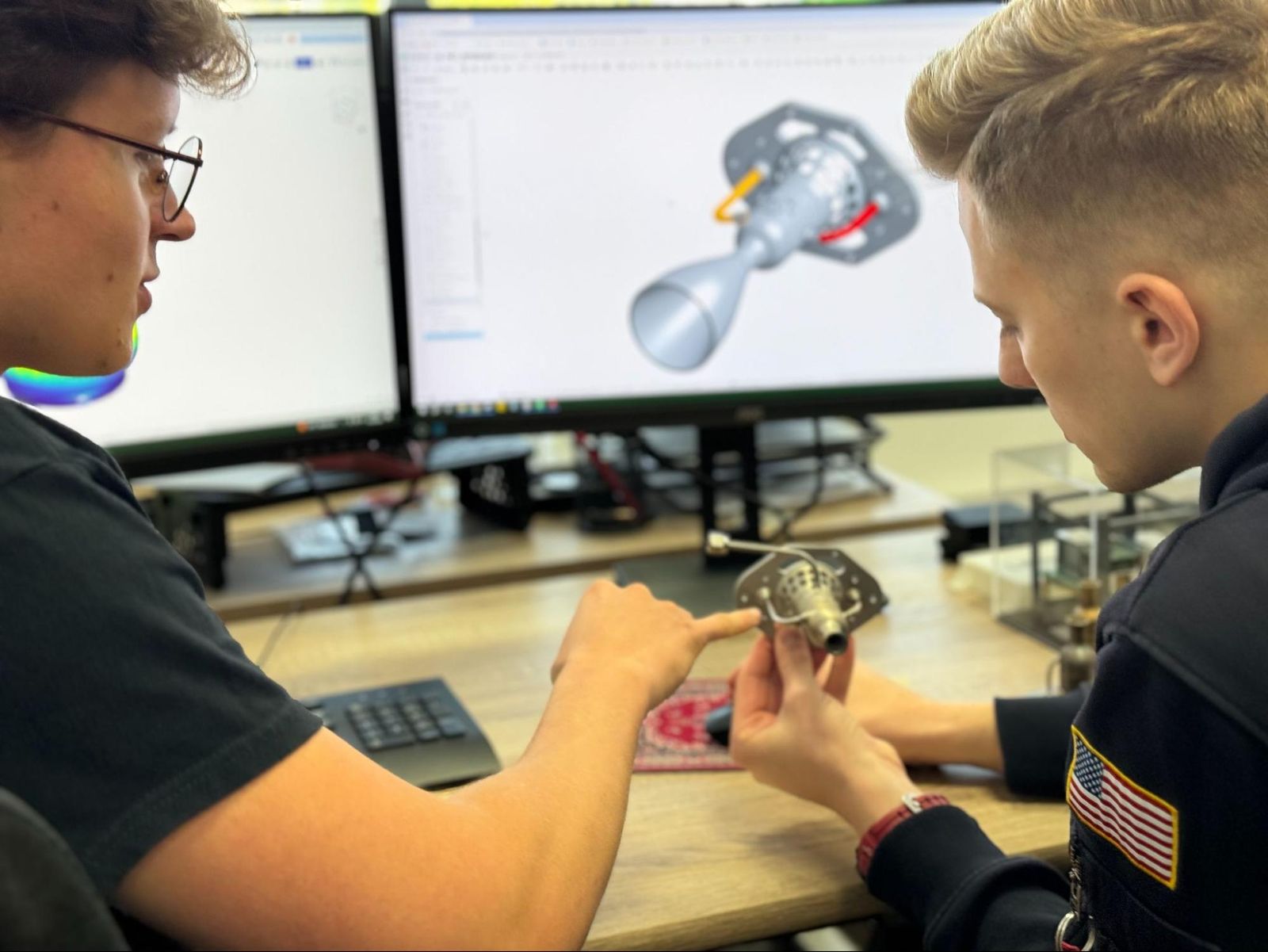

“Onshape helps a lot when we do rapid experimental design, manufacturing, and testing of the thruster for our small rocket engines,” Palacz said. “There are very different versions. With Onshape, we can easily categorize these versions, and we can easily track changes between different prototypes. For example, we do 3D printing from metal of nine different prototypes. Onshape helps track this. Designing this works better in Onshape than in SOLIDWORKS if we need to change a few parameters. And the model reveals itself with a different component and different location.

“We use it a lot because we can 3D-print it in metal and put it right to a test within two days. It is a very fast design and very fast manufacturing process and Onshape is a big part of that.”

The Onshape Startup Program

Equip your team with full-featured CAD, built-in PDM, and analytics in one system.

Latest Content

- Case Study

- Industrial Equipment & Machine Design

Reframe Systems: Transforming Homebuilding with Digital Automation and Cloud-Native Onshape

09.25.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more