5:46

From K-12 teams and competitions such as FIRST, F1 in Schools, and VEX to University teams and competitions like Formula SAE, Baja SAE, Spaceport America Cup, and more, we are excited to support the engineering and problem-solving that students do in these extracurricular activities and clubs.

Over the past year, the education team at PTC has put together new enablement material, worked with teams and STEM competition organizations directly, and added to our education offerings to help teams get right into CAD instead of dealing with the headaches of traditional installed CAD tools.

Insights from teams, new enablement materials, and the benefits of Onshape for teams were highlighted in the Onshape Live ‘23 session, “Onshape for Student Teams and Competitions.”

Read a recap of the session below or check out the full video on demand. Register for free to access all the recorded sessions from Onshape Live ‘23.

Onshape for Student Teams and Competitions

In this session, Drew Bennett and I, PTC Education engineers that have been part of and mentored teams, talk about the benefits we see for teams switching to Onshape, tips for modeling success, and some of the resources for teams getting started or wanting to improve their CAD processes.

In high school and college, we were both part of STEM competitions like FIRST, Science Olympiad, Formula SAE, and Baja SAE. I know I can speak for both of us when I say these extracurricular activities were crucial to our development and learning as engineers. Team projects are some of the best ways to apply the knowledge you are learning in class, develop teamwork skills, and have fun.

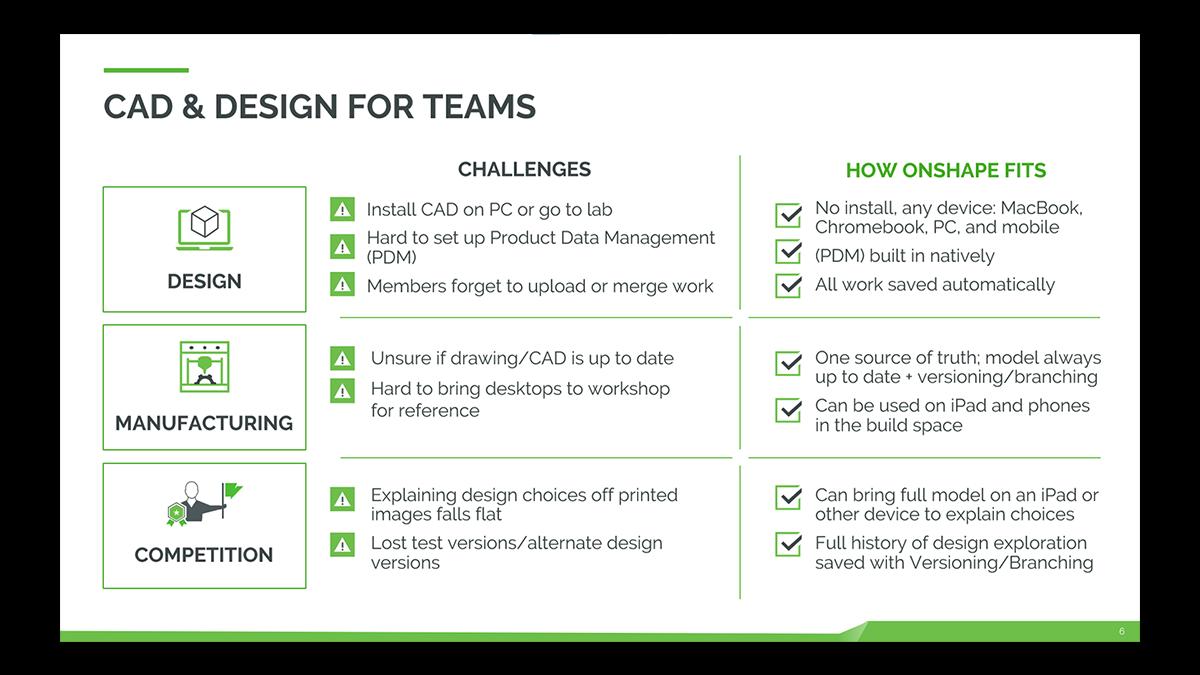

CAD is a crucial part of the design and engineering process for these projects, but the logistics of getting everyone a license, installing the programs, and dealing with files can create headaches that waste time and get in the way of progress on the actual project.

On our own teams, we’ve experienced the struggle to know who is working on what with file-based systems. Maybe a team member forgets to upload or bring their work and time is wasted in meetings, or the complicated product data management tool you set up on a server isn’t syncing properly.

Professional companies like Formlabs and Trek faced these same challenges and switched to Onshape for many of the same reasons teams are: Getting new members up and running without installing anything; working from anywhere; using any device like Macs, Chromebooks, and iPads; and built-in product data management (PDM).

STEM Competition Highlights

We work with a lot of STEM competitors doing exciting things with Onshape all over the world and at different school levels. In our session, we highlight a number of these teams and how they are using Onshape in unique and advanced ways. Definitely check out the session if you want to hear more about them.

Tips on Using Onshape as a Team

We spend a lot of time talking with teams to help them implement Onshape, so we get to learn from them what’s working best and what strategies they are using to be successful. The Onshape community of users is great and often offers up help and shares what they are doing with other teams. So, let’s talk about two teams and their tips.

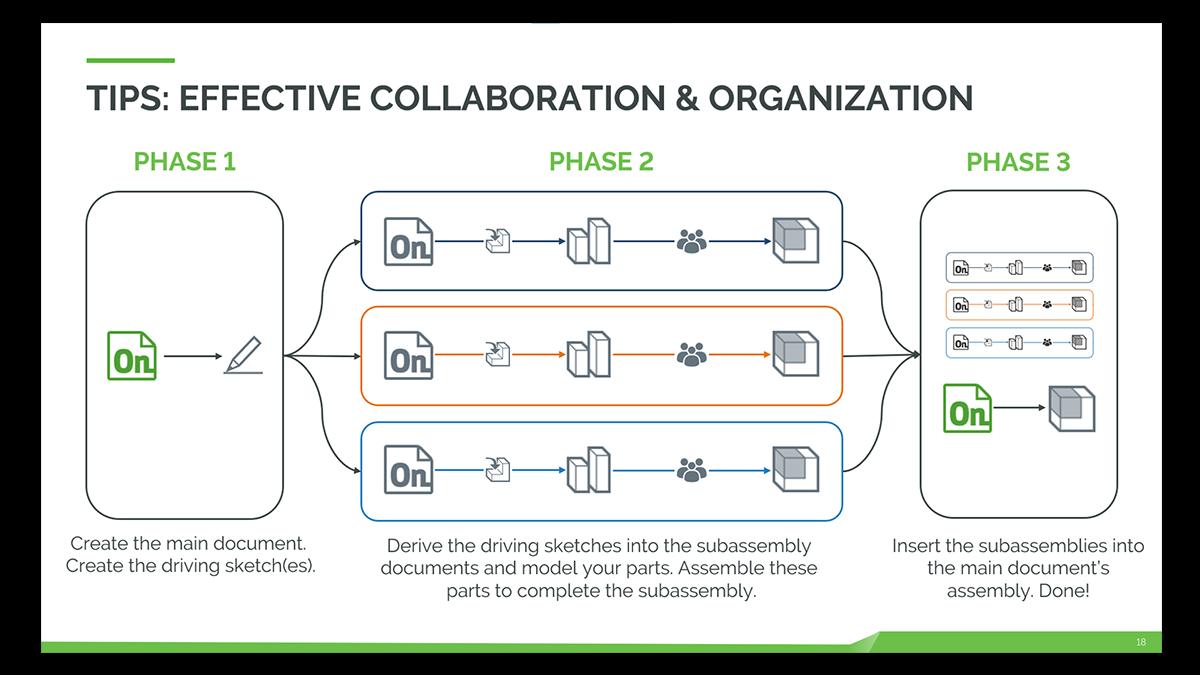

First up is FRC Team 1678, Citrus Circuits. One of the top FIRST teams in the last few years, they have a design team with about 18 students creating the CAD model for their robot. Once you have more than a couple of people working on the design, teams need to consider best practices for managing and organizing their work. Spending the time to make sure everyone understands how documents work, how to share, and when to use versioning in Onshape is key. Then you can decide how to split your project into multiple documents, when to branch or version designs, and more.

One strategy for managing your project that FRC Team 1678 uses for top-down design is to start with a main document and create initial driving sketches of important geometry. Then when that initial design is reviewed, they derive those driving sketches into new subassembly documents. In those documents, they then model parts and make the subassembly. Changes to the main document driving sketches can propagate to these parts because they reference the derived master sketches. Lastly, they assemble the subassemblies back in that main document. This is definitely a little hard to conceptualize, so watch the session recording to learn more.

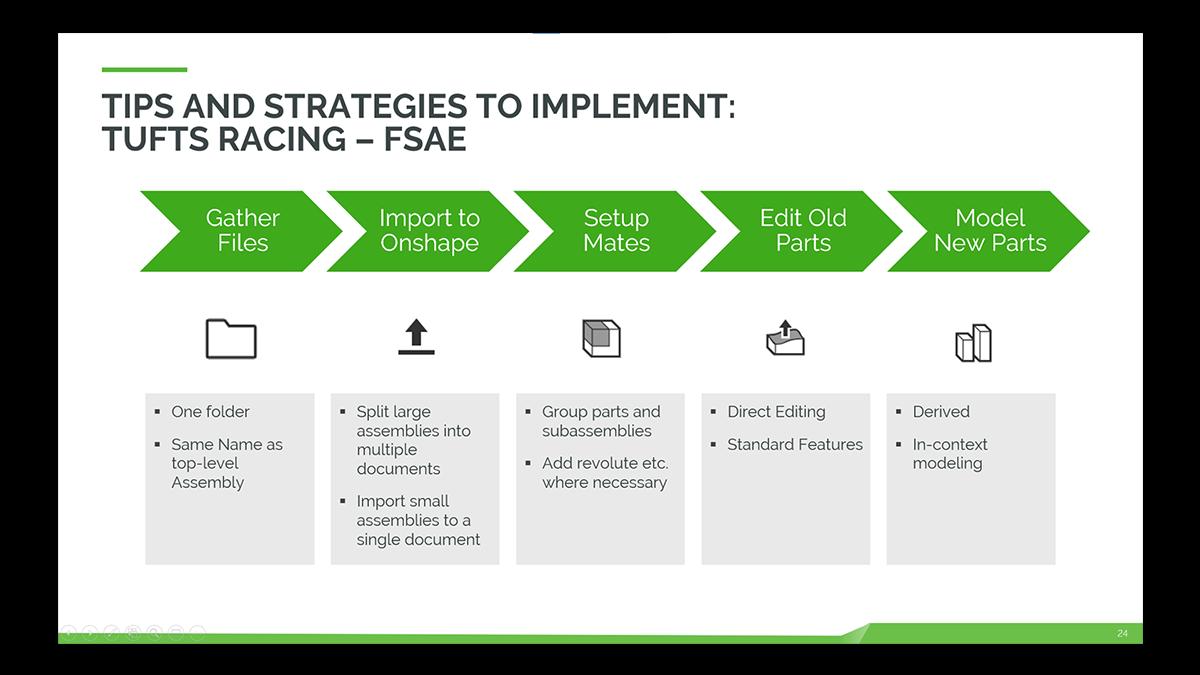

A team that I work with closely is Tufts University’s Formula Electric Racing Team. They recently switched to Onshape after using another tool for years. Over the previous year, they had been working on a new design for their car based on their old chassis, so they wanted to be sure that they could keep building off their work.

To do this, they wanted to use their CAD design from last year and continue adding to it. Fortunately, doing this is easy with Onshape. First, you need to gather all the files you want to upload. Generally, it's recommended to import your top-level assembly and the associated files in a folder. Then, upload it from your documents page. You’ll have to set up mates in the assemblies once your data is uploaded and translated.

Onshape also makes it easy to edit your old parts with direct editing tools. You’ll be able to design new parts too and use your old parts and assemblies just like you would if they were original Onshape parts.

Resources for STEM Teams Using Onshape

During the session, Drew also shared a number of resources teams have found helpful and that we recommend.

For learning new Onshape skills, there’s no better place than the Onshape Learning Center. With many learning pathways, self-paced courses, recorded webinars, and technical articles, there is a lot to go through. Here are a few that we recommend and have heard are the most useful for teams.

CAD Basics: For students that haven’t used CAD before, this course is great for getting new members up to speed on the basics.

Onshape Fundamentals: Data Management: Learn how to effectively manage your models in Onshape. Ideal for team leaders managing the design process.

Importing Data: If you are thinking about importing your design from previous years, this course will help you.

We also recommend that teams take a look at the Onshape App Store. There are a number of apps that teams have been using to advance their design with integrations like CAM, simulation, and more. Here are a couple we recommend you check out.

MKCAD Library: A library of common FIRST FRC components that you can pull right into your assemblies.

SimScale: When you need solid mechanics (FEA), fluid dynamics (CFD), and thermal simulation all done in the cloud with a free education offering.

OnScale Solve: Another option for mechanical, fluid, and thermal simulation.

Get Started with Onshape Education

Onshape for Education brings CAD out of the computer lab and into the modern era.

Latest Content

- Case Study

- Automotive & Transportation

Zero Crashes, Limitless Collaboration, One Connected Workflow With Cloud-Native Onshape

12.04.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more