8:06

Product Data Management (PDM) is a system designed to store, organize, and control access to product design data. It ensures teams collaborate effectively while maintaining version control, protecting intellectual property, and managing workflows.

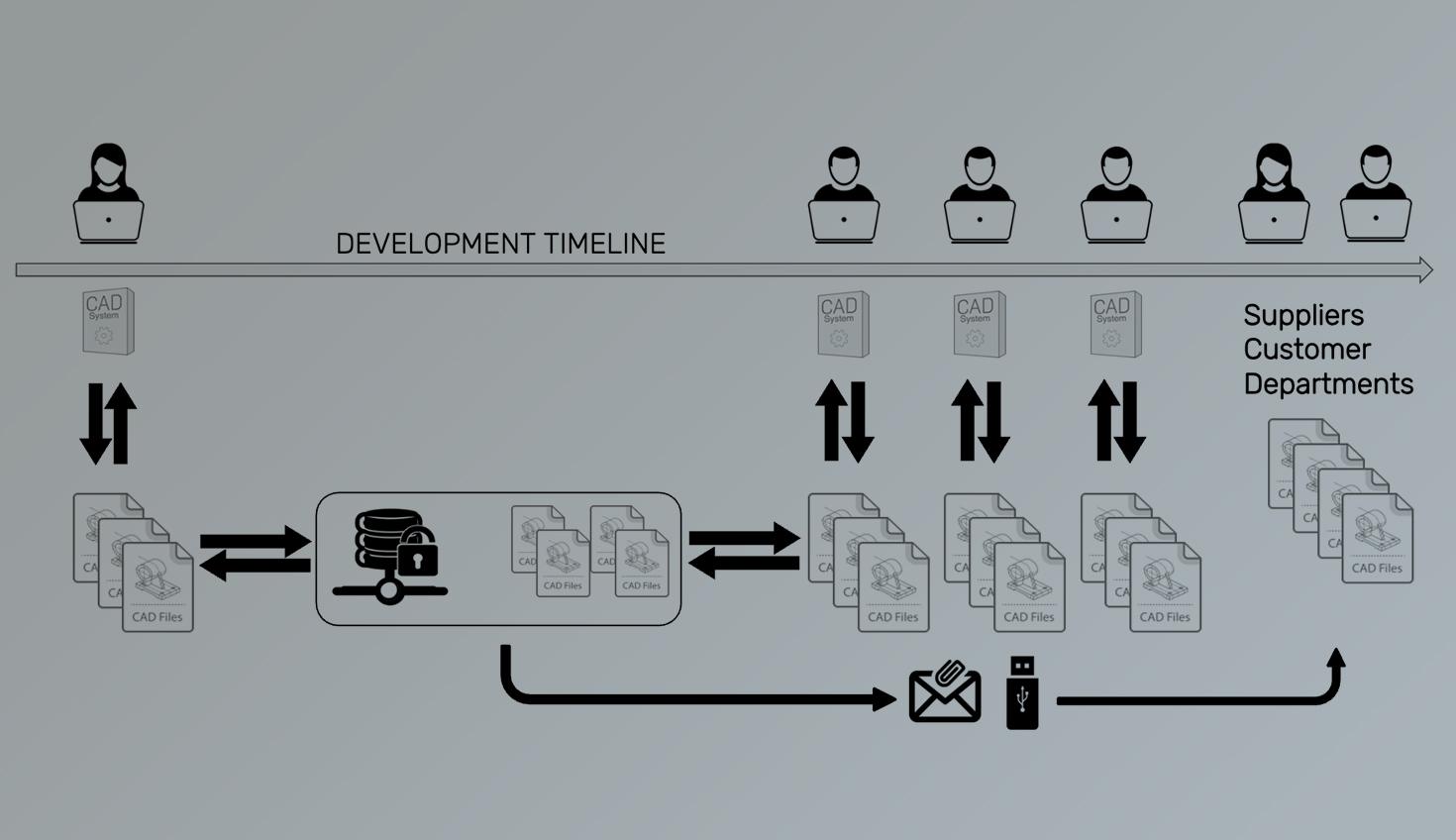

For traditional file-based CAD systems, like SOLIDWORKS and Autodesk Inventor, PDM is essential because CAD projects generate vast numbers of interconnected files — parts, assemblies, and drawings — that must be carefully managed to avoid version conflicts, lost work, or duplication.

For example, a single product usually involves hundreds or even thousands of individual part, assembly, and drawing files plus many other associated files. Without a structured system, teams struggle with inefficiencies, data corruption, and workflow bottlenecks.

Traditional PDM solutions enforce structured workflows by centralizing design files, tracking changes, and controlling who can access and modify files. This is particularly critical in medium to large teams where multiple engineers work on the same project and need a reliable way to manage revisions and approvals.

How PDM is Implemented in Traditional CAD Systems

In most traditional CAD systems, PDM is implemented as a separate system designed to organize and control CAD files. Since file-based CAD stores each part, assembly, and drawing as an individual file, PDM provides the structure needed to manage these files effectively.

A typical PDM system includes:

- A Centralized Vault: CAD files are stored in a secure database or network location instead of scattered across individual users’ machines, ensuring data consistency and accessibility.

- Check-in/Check-out Processes: Engineers check out files to make edits, ensuring controlled access and preventing unintended changes.

- Version and Revision Control: Every modification is tracked, allowing teams to maintain a clear history of changes and restore to previously saved versions when needed.

- Access Control and Permissions: Role-based access ensures that only authorized team members can view, edit, or approve specific files.

- Workflow Automation: PDM systems enforce structured workflows, helping teams manage design approvals, releases, and compliance requirements.

- Centralized Storage and Backups: Since most CAD files are created and edited locally, PDM provides a centralized repository that ensures data is stored in a secure, managed environment. This makes it easier to back up files and reduce the risk of data loss from hardware failures or accidental deletions.

By implementing these features, traditional PDM helps teams maintain order in complex design projects, ensuring version control, data security, and structured collaboration.

Advanced PDM Setups

For larger organizations or distributed teams, more advanced PDM setups are required to improve performance and ensure global accessibility. These setups extend beyond a single central server and often include:

- Data Replication Across Multiple Servers: To improve access speeds and reduce latency, companies replicate CAD data across multiple servers in different geographic locations. This ensures engineers working in different regions can access and save files without experiencing long delays. These vaults are typically synchronized intermittently — sometimes nightly — meaning the data in each vault is often out of sync with the master vault. As a result, engineers in different locations may be working with outdated versions of files, leading to inconsistencies and potential rework.

- External Access via VPNs: Since PDM systems are typically hosted on internal company servers, remote users — such as suppliers, contractors, or distributed teams — must connect through Virtual Private Networks (VPNs) or other secure tunneling methods. This setup allows external collaborators to access CAD files while ensuring security policies remain intact.

- Network Licensing Pools for Cost Efficiency: Because traditional vault-based PDM is often a separate piece of software with per-user licensing, companies frequently deploy shared network license pools to reduce costs. This model allows users across global teams to access licenses as needed, especially in “follow the sun” environments where usage shifts by time zone. While this approach can help optimize licensing expenses, it also introduces new layers of complexity in monitoring usage, administering access, and maintaining compliance.

These advanced setups help larger companies maintain performance, security, and accessibility when working with extensive design teams spread across multiple locations. However, they also introduce additional complexity in IT management, network performance, and security administration.

Challenges of Traditional PDM

While PDM provides essential control over CAD files, it also introduces significant challenges that can slow the design process. What is intended to bring order and structure often results in workflow bottlenecks, administrative burdens, and increased costs. Many engineers find themselves working around the system rather than benefiting from it.

Some of the key challenges include:

- High Costs: Traditional PDM systems require expensive software licenses, dedicated servers, IT support, and ongoing maintenance. These costs scale as teams grow and as more storage and computing resources are needed.

- Administrative Overhead: Managing a PDM system requires dedicated administrators to enforce access controls, troubleshoot issues, and ensure that data is properly backed up and secured.

- Slow, Serial Workflows: The check-in/check-out process, designed to prevent file conflicts, often slows teams down. When an engineer needs to edit a file, they must wait for others to finish their work and check in not only that file but also any dependent files. These serial delays — often referred to as "the siloed data problem" — become a frequent, daily bottleneck, significantly slowing the design cycle and hindering collaboration.

- Users Bypassing the System: Because PDM processes can feel restrictive, some users work around them by creating local copies of files. This leads to version confusion, lost work, and duplicate data that can’t be merged, negating many of the benefits PDM is meant to provide.

- Performance Issues: Large and numerous CAD files require significant data transfer between local machines and PDM servers. For remote teams or users on slower networks, this can lead to intensely frustrating delays in opening, saving, or checking in files.

These challenges mean that while PDM helps control data, it often does so at the cost of efficiency. Rather than accelerating design, it can introduce friction that slows innovation and collaboration.

Understanding File-Based Version Control: What’s Really Being Tracked?

In traditional CAD systems, the file itself is the core unit being tracked. When PDM provides version control, it isn’t capturing every change — it’s simply saving the last recorded state of the file at the moment it was checked in.

This means:

- You’re only tracking snapshots, not continuous history. If an error or corruption occurs between saves, that lost work is unrecoverable.

- Saving isn’t instantaneous. Large CAD files take time to save, and if something goes wrong during that process — like a crash or network issue — data can be lost or corrupted.

- Users must manually remember to save. If a user forgets to save before a crash or mistakenly overwrites a critical change, that data is gone unless they have created a separate backup.

This limitation of file-based PDM highlights why traditional version control can’t always be relied upon to protect design data fully. The gaps between saves leave room for irrecoverable mistakes. In fact, recent surveys indicate that CAD users spend over 10% of their time recreating lost work from crashes and accidental file overwrites.

The Future of PDM: Cloud-Native, Built-In

PDM is critical to any CAD endeavor — it ensures data integrity, version control, and collaboration. However, traditional PDM, layered onto file-based CAD, often creates more friction than it solves. Cloud-native CAD and PDM change this dynamic completely, making data management seamless, automatic, and built into the design process itself.

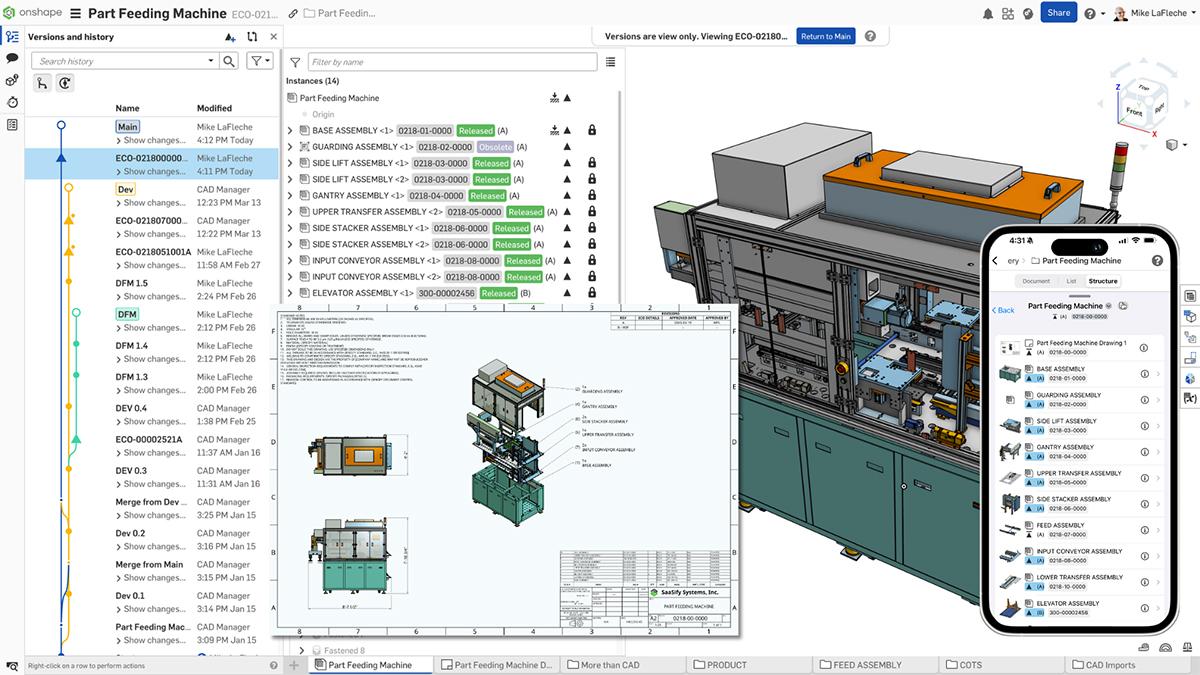

With cloud-native PDM, engineers can collaborate in entirely new, agile ways. Features like branching and merging allow teams to explore multiple design ideas in parallel, test variations without risk, and easily combine the best elements of each approach. Instead of being forced into a slow, linear workflow, teams can iterate dynamically and innovate faster than ever before.

Key differences in cloud-native PDM:

- No More Files — Everything is Recorded: Instead of tracking only the last saved state of a file, cloud-native PDM captures all design actions in real time. Every edit, every change — automatically recorded, providing infinite restore without relying on manual saves.

- Data is Centralized by Default: Because designs are stored in a cloud-based database, there's no need for separate PDM vaults, replication servers, or VPN access. Engineers collaborate in real time from anywhere. The data is stored once and never duplicated, ensuring a single source of truth. Backups are automatic and handled by the cloud CAD system, removing that responsibility from IT teams.

- True Agile Design with Branching and Merging: Engineers can explore multiple design directions at once, experiment freely, and seamlessly merge the best ideas together without worrying about losing work.

- Eliminates IT Overhead: There are no servers to maintain, no manual backups to manage, and no software installations to troubleshoot. Cloud-native PDM removes IT complexity and added costs, allowing engineering teams to focus on design, not infrastructure.

- Prevents Data Loss and Overwrites: Since every action is automatically recorded, there’s no risk of accidental file overwrites, lost local copies, or corrupted saves. Every change is preserved, and users can instantly restore any design state that ever existed.

- Enhanced Visibility for the Extended Team: Cloud-native PDM allows the entire extended team — manufacturing, suppliers, leadership, and other stakeholders — to view evolving designs in real time. Instead of waiting for updates or static file exports, teams always have access to the latest data, improving collaboration and decision-making.

- Fearless Innovation: With a fully versioned, always-restorable design history, engineers can take risks, iterate faster, and push boundaries — without the fear of irreversible mistakes.

With cloud-native CAD and PDM, data management is no longer a hurdle — it’s an invisible advantage that accelerates collaboration, design iteration, and innovation.

See the difference for yourself. Sign up for the Onshape Discovery Program today and experience a better way to design, collaborate, and manage product data.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Industrial Equipment & Machine Design

Reframe Systems: Transforming Homebuilding with Digital Automation and Cloud-Native Onshape

09.25.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more