Onshape fundamentally improves sheet metal design workflows by letting you update the folded, flat, and table views simultaneously, preventing the creation of parts that cannot be flattened. Additionally, multi-part Part Studios allow sharing and referencing geometry between the sheet metal and mating parts to ensure proper fits.

However, avoid using multi-part Part Studios to place standard components such as PEM brand fasteners. Instead, this helpful Tech Tip explains how to assemble and manage PEM fasteners effectively.

What are PEM Fasteners?

PEM fasteners utilize self-clinching technology to provide threaded attachment points for sheet metal parts. They are an excellent solution for industrial applications where fasteners are preferable to alternate assembly techniques.

How to Use PEM Fasteners

The following steps explain the best workflow for installing PEM fasteners into your sheet metal designs.

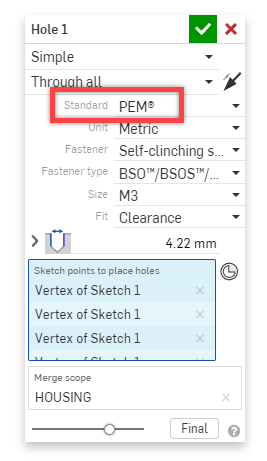

In the Part Studio

Use the Hole tool. Select the PEM standard to ensure correctly sized installation holes.

In an Assembly

Create a subassembly to populate the sheet metal part with PEM fasteners.

The Standard Content library includes Unified and Metric sizes of PEM self-clenching, nuts, pins, standoffs, and studs. Using the Standard Content library saves you the trouble of importing and maintaining a folder of fasteners.

The Replicate tool reduces the effort of mating several identical PEM fasteners. You can fully define several part assemblies with only a few mates.

Pro tip: Use Snap Mode to mate fasteners quickly.

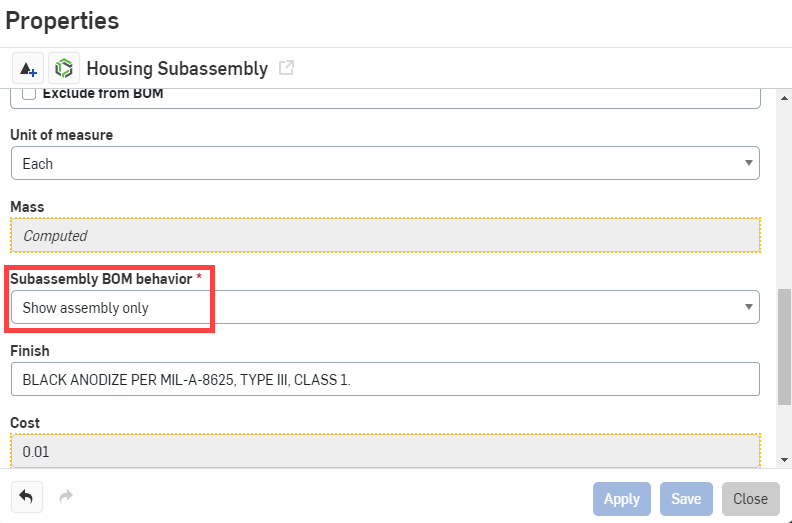

Managing BOMs

Uninstalling self-clenching PEM fasteners may damage sheet metal parts. Therefore, it's common to procure these as an inseparable assembly. It is preferable to display this subassembly as a single line item on next-level BOMs.

Edit the “Properties” of the sheet metal subassembly and change the “Subassembly BOM behavior” setting to “Show assembly only.” Now, referencing BOMs will display this assembly as a single item. See this Tech Tip to learn more about subassembly BOM behavior.

PEM fasteners with self-clinching technology are helpful for multiple industry applications. The techniques described in this article and shown in the video below will help you employ these items more effectively in your designs.

Interested in learning more Onshape Tech Tips? You can review the most recent technical blogs here.