1:35

Converting legacy sheet metal into Sheet Metal parts that users can unfold in Onshape is a straightforward process.

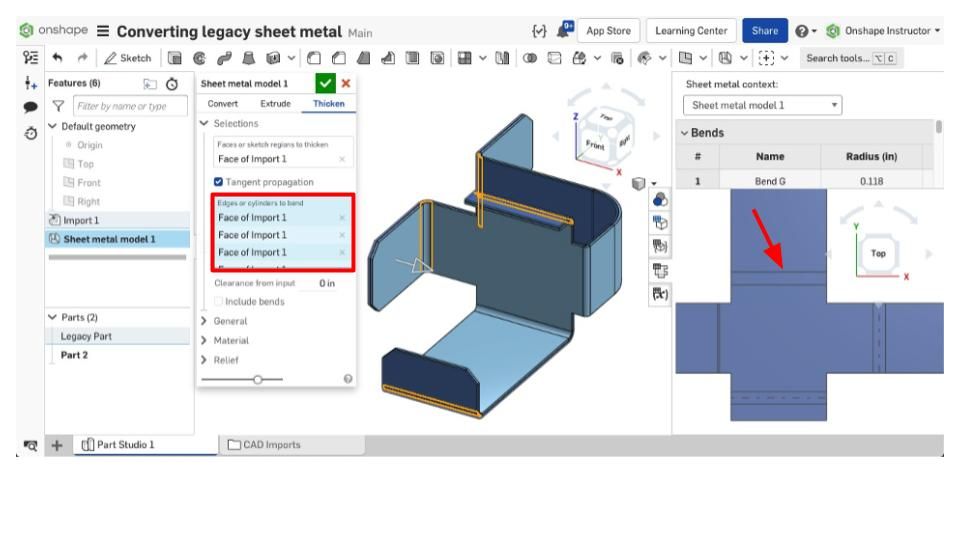

You can simply import the legacy part, then open the Sheet Metal Model feature.

There you can select the Thicken tab, check Tangent Propagation, and then select one face on the part. Tangent Propagation automatically selects the tangent faces, so manually selecting each face is not required.

Once selected, a flat pattern preview appears inside the Sheet Metal table and flat view flyout.

Tangent edges appear in each bend location within the flat pattern, but no bend centerlines are present. Click the inside edges or cylinders to bend and select each bend on the imported part.

After that, you can enter Sheet Metal parameters such as material thickness, bend radius, K-Factor, and reliefs. You can flip material thickness direction if required. If the thickness or inner bend radius is unknown, use the Measure feature.

After accepting the changes, two parts are present: The legacy part and a Sheet Metal part.

If the imported part is no longer required, right-click on the part and select Delete.

When converting imported parts to Sheet Metal, avoid importing parts with formed features. If you can’t, use direct editing tools and remove them before converting.

Before converting, every bend should have rounded corners.Make sure to remove any interference or coincident edges and diagnose any errors based on the flat pattern displayed.

Using the Thicken workflow, legacy sheet metal parts can be imported and converted to workable Sheet Metal models in Onshape. Once imported and converted, the part will act like a Sheet Metal part created from scratch in Onshape.

Learn more about this process by watching the video below:

Want more on Onshape’s Sheet Metal functionality? Attend the live instructor-led class, Simultaneous Sheet Metal Training.

Interested in learning more Onshape Tech Tips? You can review the most recent technical blogs here.

Latest Content

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more