3:39

DHL is the world’s leading logistics company with 380,000 employees worldwide serving more than 220 countries and territories. While most consumers associate DHL with package delivery – they deliver more than 1.5 billion parcels annually – the company is also a leader in large-scale contract packaging. For example, DHL recently teamed up with a multinational pharmaceutical company to produce 30,000 promotional displays within one business day and then managed delivery of 14 million units of the product to 20,000 locations.

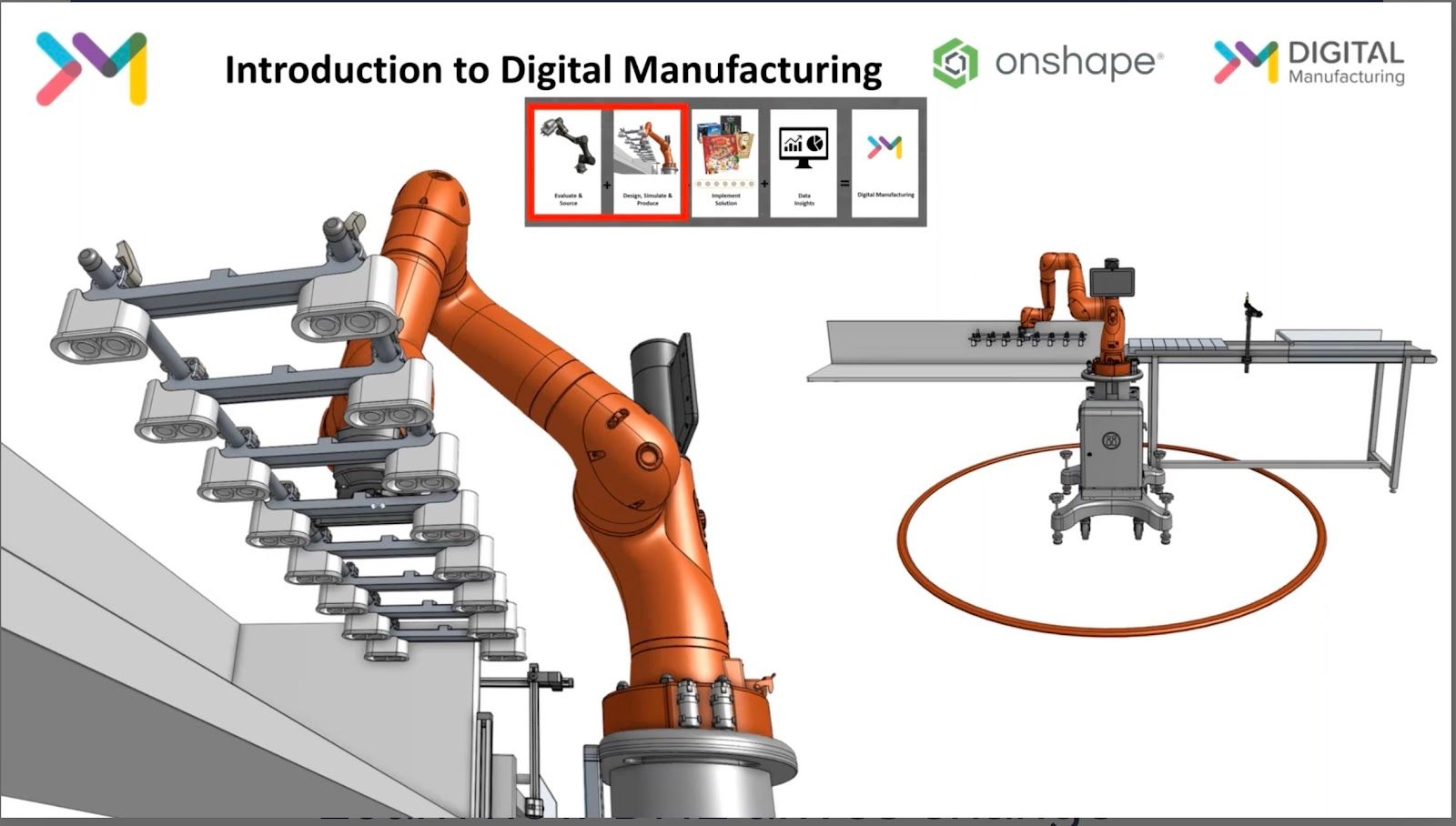

To continually improve upon these kinds of supply chain solutions, DHL runs an internal innovation and entrepreneurship program called “Start-Up Lab.” Based in England, DHL’s Digital Manufacturing Group is an outgrowth of this innovation lab. The R&D unit focuses on creating custom low-cost, highly flexible and agile robotic systems to serve the logistics market. The engineers are specifically developing automation systems that address increasing labor costs and decreasing labor availability.

“The decreasing availability of labor has actually been made more acute during COVID, because it affects the ability of people to work close together onsite,” notes DHL’s Redland Sanders, Technical Director of the Digital Manufacturing Group.

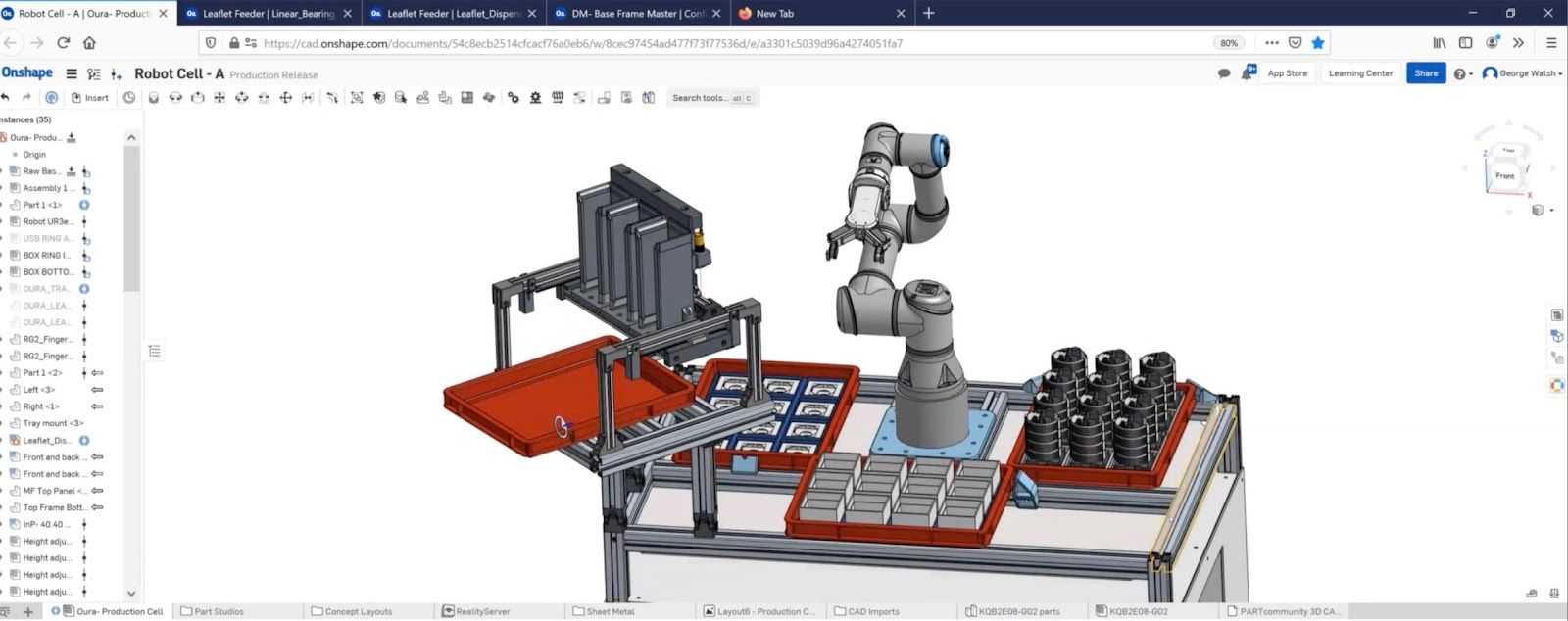

During a recent digital manufacturing webinar co-sponsored by Onshape, “How DHL Drives Change From the Digital to the Physical World in the Design Process,” Sanders and DHL product development engineer George Walsh shared a glimpse of their daily design challenges to support contract packaging.

The engineers shared how they recently helped a European candy company, which used to pack chocolates into 1.2 million Christmas Advent calendars by hand, dramatically improve the efficiency of their assembly line by adding two robots.

“These robots now have essentially taken two production lines of 22 staff and they've allowed us to do the same amount of work with about seven people currently, significantly relieving that pressure strain at a peak time of year when you've got lots of other companies all asking for the same kind of labor,” Sanders says.

Onshape is “Like Time Traveling” for Engineers

Cloud-based Onshape is the only CAD platform that enables multiple engineers to simultaneously work on the same product design.

To design and build their automated packaging equipment and 3D-printed modular conveyor belts, DHL’s Digital Manufacturing Group relies on PTC’s Onshape, the only cloud-based product development platform that combines a powerful CAD system with built-in data management and real-time collaboration tools.

During a demo of Onshape’s built-in data management features and CAD collaboration tools, Walsh praised the platform’s comprehensive Edit History that permanently captures all changes in the evolution of the design, allowing engineers to instantly revert back to any prior stage. The audit trail allows users to experiment with new ideas without fear of having to recreate the original design if they go down a nonviable path.

“With a click of a button, you can go weeks back or months back to an earlier version,” says Walsh, “It's like time traveling.”

“Onshape removes the need for you to manage your own versions. With traditional CAD, you've got a file and you have to make sure that you're really strict and disciplined with your naming convention,” adds Sanders. “That's now baked in and integrated into the design process. You've always got that full chronology, and that's massive.”

Watch the DHL Digital Manufacturing Webinar

During the recorded video webinar, Sanders and Walsh give an engineer’s view on numerous aspects of their Onshape experience. Discussion topics include:

- The Benefits of Using a Software-as-a-Service (SaaS) Platform – No need for upfront CAD licenses, expensive hardware or ongoing IT maintenance.

- Rapid User Up-Skilling – How DHL’s Digital Manufacturing Group onboards new engineers in Onshape using collaborative tools like Follow Mode and the online Learning Center’s self-paced courses.

- Real-Time Team Collaboration – Shared product development and concepting, and enablement of remote work and collaboration. How cloud-based CAD facilitates design reviews.

- Shared Library of Parts – Up-to-date design library accessible to the entire team.

- Migration of Legacy Data – Advice on how to move old legacy designs into Onshape.

- Flexible Configurations – Fast and powerful toolsets to make model variants.

- CAD Stability – How cloud-based Onshape protects you against CAD software crashes.

To learn more about how DHL uses PTC’s Onshape cloud product development platform to improve collaboration and accelerate the design of automation and robotics equipment, watch the video.

Or see for yourself how Onshape can accelerate business success by requesting an Onshape demo.

Latest Content

- Case Study

- Automotive & Transportation

Zero Crashes, Limitless Collaboration, One Connected Workflow With Cloud-Native Onshape

12.04.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more