6:52

At LiveWorx 2023, three members of the Red Hawk Robotics team – Addy Hickey, Gavin Chaires, and Kate Urchuk – presented a breakout session titled, “Ultra-Fast Design Process Rockets High School to a World Championship.”

Here’s a recap of their session!

Who is Red Hawk Robotics?

Team 2713, Red Hawk Robotics, is a FIRST Robotics team from Melrose High School in Melrose, Massachusetts. Founded in 2009, the team currently consists of 35 student members and 10 mentors.

With this many students all working together to build one competition robot, keeping the team organized is important. Red Hawk Robotics breaks their team down into four subteams that handle different responsibilities:

Mechanical Subteam:

- Prototype each subsystem;

- Design the robot using Onshape;

- Manufacture the robot using both subtractive and additive machines.

Electrical Subteam:

- Install control system components;

- Wire up control system components, motors, and sensors;

- Ensure wiring is tidy and easy to maintain.

Programming Subteam:

- Write robot control code using Java;

- Ensure teleoperated code is tuned to the driver and operator;

- Create and test complex autonomous routines.

PR & Fundraising Subteam:

- Participate in community events (like LiveWorx!);

- Update the community on team activities and achievements;

- Work with sponsors to ensure funding for current and future projects.

Now that we know how Red Hawk Robotics operates, let’s take a look at what challenge the team was given this year.

FIRST Robotics Competition 2023 Challenge: Charged Up

Every year, FIRST – an international nonprofit organization focused on inspiring students to learn about and pursue STEM careers – creates a new challenge for the annual FIRST Robotics Competition. Teams know that the playing field will be roughly 55 feet long and 30 feet wide and that there are standard components they can use to build their robot, but that’s about it.

In early January of each year, FIRST kicks off the competition season by revealing the game, the game manual, and sending each team sample game elements their robots will need to interact with.

At that point, teams have roughly 6 weeks to prototype, design, manufacture, assemble, program, and test their robots before they head to the competition!

For the 2023 FRC season, teams around the world played “Charged Up.” In this game, robots compete in a 3 vs. 3 match to acquire and carefully place rubber traffic cones and inflatable cubes on a scoring grid. Game elements placed on higher rows are worth more but are harder to reach. If three game elements are scored in a row, teams earn a small bonus. At the end of the 2-minute, 30-second match, each alliance of three teams needs to work together to balance on a teeter-totter system. If you’d like to see the game explained in more detail, check out the game animation below.

Like thousands of other teams around the world, Team 2713 created an incredible robot to play Charged Up, but this one made an appearance at LiveWorx. Let’s take a look at what they built!

Team 2713 Red Hawk Robotics 2023 Robot: Rainbow Dash

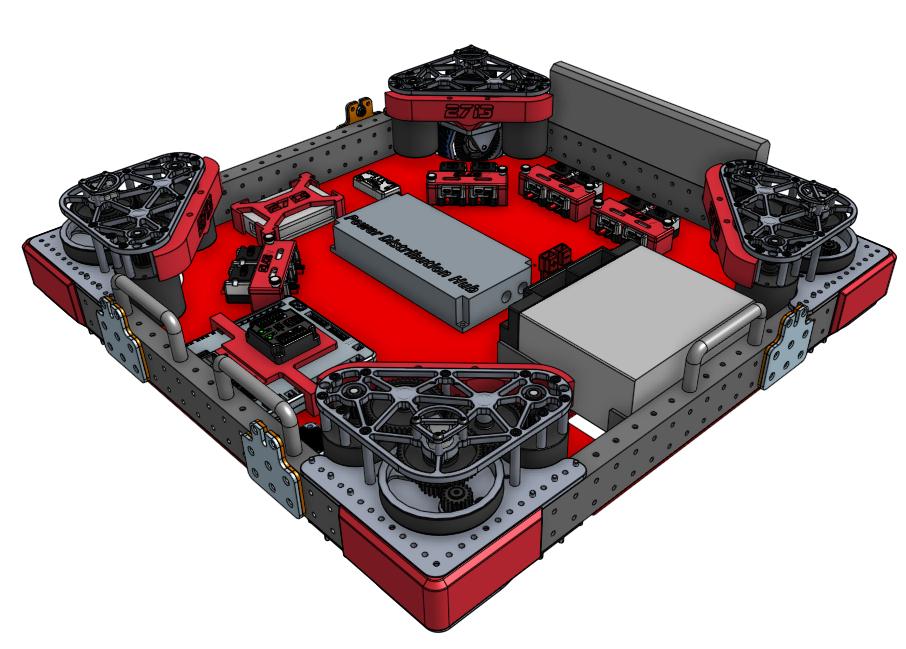

Pictured above is the model for Red Hawk Robotics’ 2023 robot, Rainbow Dash. Want to see the robot for yourself? Check out the model in Onshape!

The drivetrain of this robot is a 26.5” x 26.5” swerve drive. Team 2713 used Swerve Drive Specialties MK4i swerve modules in each corner of the frame to allow for omnidirectional movement with high-traction wheels. This was a popular choice for the 2023 challenge as the optimal driving paths were cramped and the additional maneuverability of a swerve drive allowed robots to score faster.

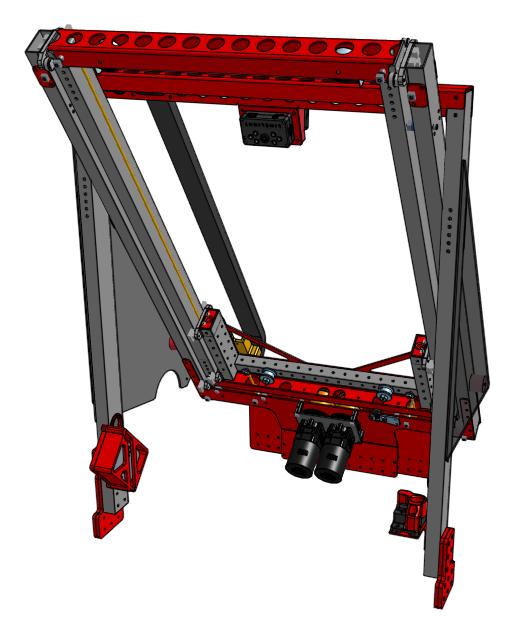

On top of the drivetrain is Rainbow Dash’s major mechanism – a continuous elevator. This “elevator” is a multi-stage extension system that is mechanically powered on the extension and retraction by two NEO brushless motors. This system extends the innermost stage by 55”, allowing the robot to reach up and out to place cones and cubes on the highest scoring areas. This was a complex system to design and manufacture, so check out the cool details and great sheet metal design!

The 4-bar and intake roller system, pictured above, completes the scoring system of Rainbow Dash by mounting to the innermost stage of the elevator. The 4-bar system allows the intake to fold inside the robot or extend to grab game pieces from the floor and also provides a bit of extra reach when scoring. The roller system can pinch cones and squeeze cubes to hold them until the robot reaches a scoring location and then quickly place them in the right spot!

The robot Rainbow Dash runs some practice cycles.

Why did Red Hawk Robotics choose Onshape?

Like many other FIRST Robotics teams, Team 2713 designs their robots in Onshape. I’ll recap some of the biggest reasons why they chose Onshape as their CAD software:

- Real-time Collaboration: One of the most important aspects of FIRST robotics is the short build season, so collaborating efficiently and effectively is key to staying on time. Onshape’s collaboration features make it easy for many members of Red Hawk Robotics to contribute to the design or review what others are working on.

- Cloud-Native Architecture: With Onshape being fully cloud-native, it was easy for students and mentors alike to use whatever device they had to work on the robot’s design or check to make sure parts were being assembled correctly.

- Versions & Branching: As the presenters put it, branching is “user-friendly” and “supports iteration and development.” Versions also “increase usability and bandwidth for our team.” Being able to split off and work on a new idea without overwriting any previous designs is powerful when designing as a team.

- Community-Curated Libraries: The FRC Onshape community has created an amazing library of common FRC components as well as a right-panel application that makes adding all of your favorite robotics parts to an assembly very simple. It’s hard to overstate how much this can speed up the design process.

- Custom Features: Using FeatureScript, Onshapers have created some Custom Features that streamline workflows and make part creation a lot faster.

- Ease of Access: Onshape’s education licensing made it quick and easy for everyone to create an account and get right to work – it only takes a few minutes to sign up and start working on the robot.

The 2023 Season Results

The official FRC 2023 season ended at the World Championship in Houston, Texas, in April. It’s safe to say that Team 2713 had an excellent season! Here are some quick highlights:

- Ranked 25th out of 185 teams in the New England District.

- Seeded 16th in the Wilson Division of the New England District Championship and joined the 6th Alliance.

- Seeded 11th in the Daly Division of the World Championship and joined the 2nd Alliance

- Engineering Inspiration Award Winners at the SE Mass Event!

Onshape & Program Testimonials

The Red Hawk Robotics team chose to include some great testimonials in their presentation that are worth highlighting. The first comes from Ty Tremblay, an experienced FIRST mentor of Team 2713 and Staff Software Engineer at Realtime Robotics:

“Realtime Robotics uses Onshape because that's what I was most familiar with when we decided we needed a CAD platform. I was most familiar with it through using it in FRC. The flexible pricing, lack of installation requirements, and the ability to use it in a remote work environment are why Realtime Robotics still uses Onshape today.”

Betsy Giovanardi, the CAD and architecture teacher at Melrose High School and Woodie Flowers Finalist Award-winning mentor of Team 2713, had this to say about Onshape:

“I feel so fortunate that I had to switch to Onshape when the pandemic required remote learning. The online access and collaborative nature of the software allowed me to keep teaching. Now that we have returned to in-person classes, I’m staying with Onshape due to all of its benefits. This was a silver lining to the pandemic!”

Whether using Onshape for your FIRST Robotics team, in the classroom, or in an industrial setting, the ease-of-use and built-in collaboration features make it an excellent choice!

Thank you to FRC Team 2713, Red Hawk Robotics, and all of the students and mentors who made this presentation possible. We’re excited to see what Red Hawk Robotics creates in the future!

CAM Studio for FRC Teams

Access CAM Studio Free with Your Onshape Educator Plan

Latest Content

- Case Study

- Consumer Products

BOA Technology: Redefining Outdoor Fit Equipment with Cloud-Native Onshape

11.03.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more