Who would have thought a veterinarian would create an environmentally friendly way to ship goods around the world?

Well, it’s not that far-fetched of an idea for Alan Holford, a former vet who believes his new venture has a doggone good chance of helping remake logistics into an efficient process that will reduce carbon emissions.

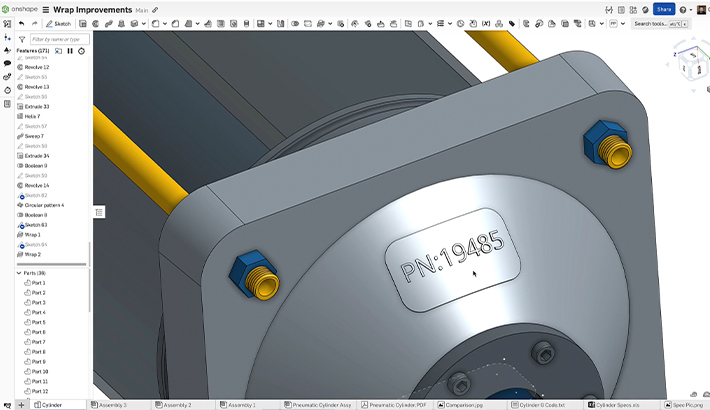

It all comes down to a box, that is BoxTube. It’s the name of his company, and it’s a way of explaining his ambitions. The “Box” is a reusable box that will use various logistical methods — including one designed by his company — as part of an open-loop, green structure of moving products. The “Tube” would be realized in the future, when shipping possibly goes underground and moves by tunnels (or “tubes” as they say in Holford’s home country, England). But sticking with the present, the company is creating machinery that loads as many as 600 boxes onto a truck (or “lorry” in England) and 16,000 boxes onto a 10-car train in one minute.

“With our system, you could potentially have a network of smaller warehouses that are able to take lorry-loads of deliveries, and then just the vans go that shorter distance to do that local area and do it on a regional basis,” Holford said. “That could save thousands of tons of CO2 a year.”

Alan Holford

Alan Holford

Creating an Efficient Delivery System that Won’t Go to the Dogs

Holford started thinking about a new line of work when treating animals. Shipments carrying veterinary medicine came in plastic boxes that, once emptied, were taken back by the delivery company the next day.

“Many deliveries are in a closed-loop system,” he said. “A lot of stuff is being delivered using loads of disposable cardboard and plastic. I liked that idea of this open-loop system, and it was there in the back of my mind.”

The lure of improving delivery got stronger as he saw companies explore shipping packages by drone. If they could attempt to localize delivery by air, he thought, why not consider going in the other direction, underground? But just as he realized an underground network would be costly, among other obstacles, he came up with the idea for his BoxTube loading system.

The system would be set up on the stages of a supply chain, from warehouses to delivery areas. It would, Holford said, be compatible with vans, train cars, cycle couriers, delivery robots, and automated smart city networks, maybe even those underground.

“It can be adapted to work with several sizes of container, as long as the size is fixed for each user set up. The solution can then load or unload the boxes rapidly, simultaneously, or individually to enable multiple drop-off locations of just the right boxes for each location.”

The goal is to be fast and green.

“Switching loads from vehicle to vehicle and transport mode to transport mode is a hassle-free activity,” Holford said. “Not only can the most economic and sustainable mode be used for each leg of the journey, but loads can be consolidated for legs of journeys to minimize inefficient use of load space.”

Arriving in the Nick of Time: A Cloud-Native CAD and PDM Package

Holford initially used off-the-shelf parts to create his product but realized he needed to design new ones for a loading system that could work with containers of varying weights and many transport vehicles. The CAD software he had just started using stopped working almost as suddenly — and just as he had created many designs. It was time to find a proper CAD for startups.

“I read some articles about the best cloud-based CAD software and found Onshape,” he recalled. “I had a look through your videos and realized it was a great solution for me.”

BoxTube qualified for the Onshape Startup Program. The program provides BoxTube and other qualifying hardware startups access to Onshape Professional, a fully cloud-native CAD and PDM package with integrated simulation and rendering tools. Onshape got Holford back to the drawing board and enabled him to continue a critical collaboration on his product — finishing his first prototype — with an engineer at Cranfield University in England.

“I was able to show him all the stuff I am doing on Onshape,” Holford said. “Because his printer was set up to use with AutoCAD, what was really good with Onshape was that I was able to save it in the file types that he can then work with. He opened them in AutoCAD and was able to use them straight away to do the 3D printing.”

BoxTube and Onshape: Revolutionizing Logistics with CAD for Startup

Holford had little experience with CAD before he started BoxTube, so he’s happy Onshape isn’t complicated and a stumbling block to realizing his design ambitions.

“Some of the other stuff I’ve done with Onshape is create things that interact with this sort of metal tubing that I’ve used to design the frame that supports the whole structure,” he said. “I was able to measure all the different angles and design a model of this to extrude in the system, and then I can design things to attach to it. It’s been easy to use, and I’ve got absolutely no artistic skill or design skill, or any of that background really.”

Holford expects to move beyond 3D printing and use other forms of manufacturing to create materials that will be able to withstand the weight of shipping. He wants Onshape to be part of that process. Currently a one-person operation, he envisions BoxTube someday having a team of engineers; Onshape’s real-time responsiveness will let his team always share the latest version of files.

It's the kind of speed and universality that he wants BoxTube to have as its central trait. He said that a fast and compatible shipping system would fully use trucks, trains, and other delivery systems, reducing their numbers on roads and optimizing the time in which, say, a reusable box for a veterinarian gets from point A to point B.

The Onshape

Startup Program

Equip your team with full-featured CAD,

built-in PDM, and analytics in one system.