There are many reasons why a company may be looking to acquire a new CAD system, such as costs and capabilities. However, finding the right CAD system for your product development team can be a minefield. Where do you even start? If you are buying a CAD system for the first time and have no previous experience, it’s even harder.

The number of systems on the market today makes it impractical to test every single one, so narrowing down your choices based on specific criteria is a good place to start. Once you’ve made a shortlist, you’ll then need to conduct a more in-depth review before making your final choice. Design software is complex, so it can be a long drawn-out process. However, it doesn’t have to be if you focus on what’s truly important to your business.

Evaluating Cost vs. Capabilities

More CAD features usually equate to higher costs, but it’s not a linear relationship. Once you reach a certain level, there’s a sharp increase in price for only a moderate increase in capability. You could easily pay 50% more for only 10% extra functionality.

So let’s talk money. Compared to many other business systems, design software is an order of magnitude more complex. It’s also an order of magnitude more expensive.

One reason why companies are switching from their current vendor is the cost itself – but there is also the lack of perceived development in the product they are paying for. Some vendors are viewed as relying on their “cash cow” product lines to fund the development of new products or services that they intend to sell in the future or that address different industries and markets entirely. Why should you pay for something you will get no benefit from?

There are two types of software licensing available: Upfront license costs followed by annual maintenance fees, and the subscription-based Software-as-a-Service (SaaS) delivery option in the cloud.

The traditional upfront license cost and annual maintenance fee are flawed in many ways. First, the business model requires a sizable initial investment – the maintenance fee is payable in advance, so it’ll cost you the license fee plus the maintenance fee from day one. Second, the ongoing maintenance fees are hard to swallow if you don’t think you are getting what you pay for. For customers who “drop off” maintenance and continue to use their already paid-for perpetual license, they will no longer get software updates or support. The danger here is if their supply chain or customers are using a later version of the software, there will be file compatibility issues. The only way around this is to start paying the maintenance fees again, but the vendor is likely to charge back payments for every year that the customer missed. Sometimes it’s cheaper just to buy a new license.

Subscriptions are a popular choice for customers and vendors alike. For customers, it means a lower barrier of entry with less cash required upfront. The budgeting and approval process is simpler (your CFO is likely to agree) and the return on investment is easier to calculate.

For legacy on-premiseCAD and server-installed Product Data Management (PDM) software, the total cost of ownership is considerably higher than cloud-based design and data management solutions. Workstation-class computers, racks of servers and other kinds of IT overhead costs increase the necessary level of investment required to get up and running.

Money aside, if your current CAD system doesn’t do what you need it to, you’ll likely be on the lookout for a better solution. There are very few geometries that can’t be modeled by every CAD system, but there are certain industry-specific geometries that can only be modeled by the self-proclaimed “high-end” systems. These are typically features like Class A surfacing, used predominantly in the automotive and aerospace industries. For those niche applications, you’re going to have to shell out big bucks for the privilege, but for everything else, “mainstream CAD” is the way to go.

Don’t assume that a CAD system with hundreds of features is the best platform for your company. More features usually means more money, but it’s not a linear relationship. Once you get to a certain level of capability (addressed by the mainstream market), there’s a sharp increase in price for only a moderate increase in functionality. You could easily pay 50% more for only 10% extra functionality.

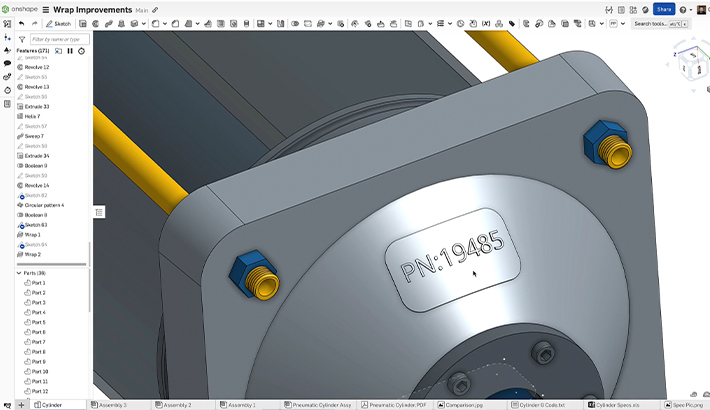

If you can’t afford these high prices, what are your options? Submitting feature requests to your CAD vendor is one option, but they may not be implemented for years, if at all. Third-party add-ons are another available option. If you need a feature that is not part of any CAD system, you could write your own. This may not be as difficult as it sounds, depending upon the architecture of the CAD system you choose.

Things to Consider Beyond CAD

Many of the CAD systems on the market today have been around for decades and, to a certain degree, they all work in a similar way and are similar in their capabilities. This makes selection even harder, so you should avoid focusing purely on CAD features. Data created by CAD is used throughout your company and beyond, so investigate the suitability of any system for your design teams, your company and your extended enterprise – especially if they are spread across multiple locations.

File-based CAD systems make it difficult for teams to share data and work on the same projects even with a dedicated data management system. PDM software is often not included and must be purchased separately.

Other key questions to ask when conducting your research:

1. Does the platform include release management and approval workflows?

2. Do you need data reports and business >analytics?

3. From a logistics standpoint, what kind of hardware is required and how easy is it to deploy a fully-configured system to a new user?

4. If you don’t have a dedicated IT team, how much work is involved in ongoing maintenance for workstations, servers, software downloads, installs, service packs, and upgrades?

These are questions you can ask at your first product demo.

Product Trials and Pilot Projects

Once you’ve seen the demo and asked all the questions, it’s time to try out the CAD platform for yourself. A product trial or pilot project is your opportunity to put the system through its paces to see how it performs in your environment. Testing how the software handles your unique modeling and detailing challenges is reasonably straightforward – shoehorning the software into your existing design processes, not so much. While the methods used to create parametric models and detailed drawings are fairly standard across the board, every CAD software has its own unique way of managing data which is particularly relevant to your design process.

Understanding how a new system will impact your business is far more important than simply checking off a laundry list of CAD features. One of the biggest and most costly mistakes often comes from trying to map your existing business processes to an off-the-shelf design and data management system. While evaluating new tools and new technologies, it’s worthwhile to explore how they can be used to not only re-engineer and improve your design processes, but your business as a whole.

Implementing a new CAD and PDM system takes time and resources, so it’s important to get it right. If you don’t spend enough time upfront on due diligence, you may not achieve the desired outcome of selecting the right system for your company. Everybody is time-constrained and busy with ongoing projects and deadlines, so the most important thing is to create a plan of action before you start and to stick to it as best you can.

Here is a list of “Do’s and Don’ts” that you should consider before any evaluation:

-

DO plan ahead and dedicate the time to review the product in-depth. It may not be possible to test everything, but don’t be tempted to just focus on the problem that prompted you to look for alternative solutions in the first place. You may find a system that addresses your immediate needs, but you should spend more time investigating how the system can be used to improve your entire design process.

-

DO choose a small, but typical, design project to test how the system performs in your environment. A live or upcoming project is best – replicating an existing project often compels you to replicate the same steps as before which may not reveal any gains in efficiency.

-

DO assign more than one person to the evaluation. Not only does this help reduce the time burden and provide a valuable second opinion, but it also helps you test how the system fares when working in teams. If you are a manager asking someone else to conduct the review, make sure you choose somebody who is willing and is able to be objective.

-

DO involve colleagues outside of engineering. Your end-to-end design process includes many people outside of the design department. Getting their input on potential process improvements is vital.

-

DO review training materials. No matter how experienced you are, the only way to get the most out of a new system is to take training, whether that be classroom training or self-paced video training. This takes extra time, of course, but it’s essential if you are to do your evaluation justice.

-

DO record and review your progress with the vendor at predefined intervals and ask for help if you need it. Keeping a list of questions and issues and reviewing them with the vendor gives them the opportunity to demonstrate how a particular task is performed.

-

DON’T focus purely on CAD features. Conducting an apples-to-apples comparison is not always the best way – more features does not necessarily make a system better. Focus on every aspect of your design process to see how it may impact your entire business.

-

DON’T assume the system can or can’t do something. If you’ve used another system before, it’s very easy to assume that all systems work the same way. They don’t. Use the review with the vendor to address any concerns you may have.

-

DON’T focus too heavily on legacy data. Importing and reusing data from your old system and from external suppliers is important, but it shouldn’t be your sole consideration. You won’t find any system that can import parts and keep the feature tree intact, so if you need to modify legacy data, investigate the new system’s direct editing tools. Speak to your vendor about the best strategies for data migration.

Get Your Free Guide to Modernizing Your CAD System

Every CAD company says their system is the best. Why wouldn’t they?

The truth is that only you can decide which design tools are the best fit for your company. “Modernizing Your CAD: 7 Criteria to Consider” offers a pragmatic and comprehensive checklist to jumpstart your evaluation process.

Think of it as a cheat sheet for what to ask professional 3D CAD vendors when they’re demonstrating their products. The guide explores the most important criteria to consider when comparing CAD systems, including:

-

Parametric Modeling Tools

-

User Interface

-

Total Cost of Ownership

-

Technical Support and Training

-

Process for Updating Software

-

Full CAD Ecosystem

-

Security and Reliability

CAD is the backbone of your business. Download your free copy of the “Modernizing Your CAD” guide today to help you determine which system is the best fit for your product development team.

(This post was originally published on 09/19/2019, and updated on 07/01/2021.)