According to an HMI/Forrester Consulting survey,

-

97% of manufacturers are facing challenges in collaboration and productivity, which can impact their ability to innovate and delay responding to customers’ needs.

-

The majority of business leaders realize that better collaboration can improve product quality (88%), time to market (86%), and also improve sustainability – with 82% of respondents believing better communication between design and manufacturing teams can significantly reduce material waste and emissions.

-

Despite this, almost three-quarters (71%) of business leaders are concerned about the lack of synergy between their design and manufacturing teams.

A majority of manufacturers today are locked into file-based CAD/CAM solutions that obstruct collaboration between design and manufacturing. Is it a surprise then that business leaders are concerned about the gap between design and manufacturing teams?

How File-Based CAD/CAM Fails

File-based CAD/CAM systems present significant challenges that hinder seamless integration and operational efficiency:

Data Fragmentation

Storing CAD and CAM data in separate files often leads to versioning issues. Changes in the CAD model may not propagate to the CAM file, causing inconsistencies and errors during production.

Manual Updates

File-based workflows require engineers to manually transfer and update files between systems, increasing the likelihood of human error and slowing down the design-to-manufacturing process.

Limited Collaboration

File-based systems often lack real-time collaboration features. Teams working on distributed networks or across different locations struggle with delays and miscommunication caused by file-sharing limitations.

File Corruption and Loss

Reliance on local storage increases the risk of file corruption or accidental deletion, which can result in lost data and production delays.

Data Compatibility Issues

Using proprietary file formats creates interoperability problems, especially when sharing data between different software platforms or vendors.

Security Risks

File-based systems often lack robust security measures, making sensitive design and production data more vulnerable to unauthorized access or cyber threats.

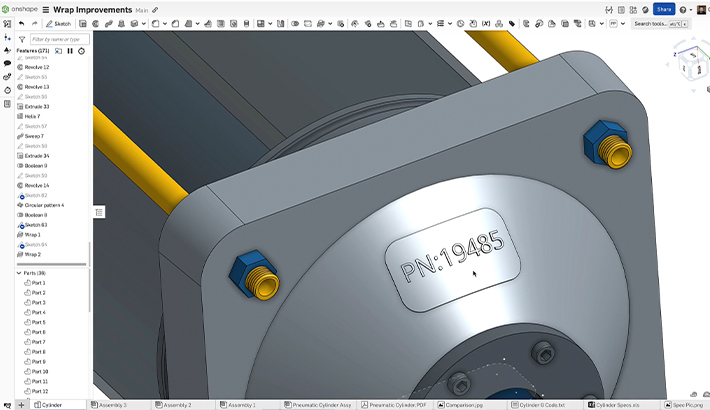

Onshape CAM Studio: A Modern CAD/CAM Integration

Onshape by PTC brings its industry-first, cloud-native, multi-tenant architecture to CAD/CAM Integration with CAM Studio.

- Onshape continues delivering value to customers with a feature-rich toolset available anytime, anywhere, on any web browser

- Leverages parallel cloud computing, reducing calculation time for both toolpath generation and machine simulations.

- Offers built-in PDM support allowing CAM programmers to version and release CAM strategies while storing the full history of CAM operations.

Available to Professional and Enterprise customers in its first release, key features include:

CAM Studio Features |

| ✔ 2.5-axis, 3-axis machining |

| ✔ Mill Turning (Planned in future release) |

| ✔ Support for a broad range of machines, cutting tools, and post-processors, instantly available to all users as new machines are added |

| ✔ Cloud HPC-enabled simulation support including collision detection |

| ✔ Support for adaptive roughing |

| ✔ Support for assembly machining |

| ✔ XYZ Coordinates for a variety of toolbits, drills, and endmills supported |

| ✔ G-Code export supported |

| ✔ Support for custom tools |

Ready to unlock yourself from file-based CAD/CAM?