Design What’s Next With Onshape

With our new offer, the Onshape Discovery Program, qualified CAD pros will receive access to Onshape Professional for up to 6 months, completely free. Fill out the form to get started.

Onshape reserves the right to change or terminate the Discovery program. I acknowledge that my personal details will be processed in accordance with Onshape’s privacy policy. Existing Onshape customers are not eligible for the Discovery Program.

Sign up for Free

Harness the power of cloud-native CAD & PDM technology

Onshape is the most widely used cloud-native product development platform that combines professional-grade CAD with built-in PDM, CAM, simulation, rendering, and more. Built for the cloud, Onshape eliminates the challenges of file-based CAD systems, delivering advanced communication and collaboration while providing greater visibility throughout the design process. Through the power of cloud technology, design teams have the right tool to design better products, faster, while reducing the overall cost of development. Design what’s next with Onshape.

Innovation Starts with Onshape

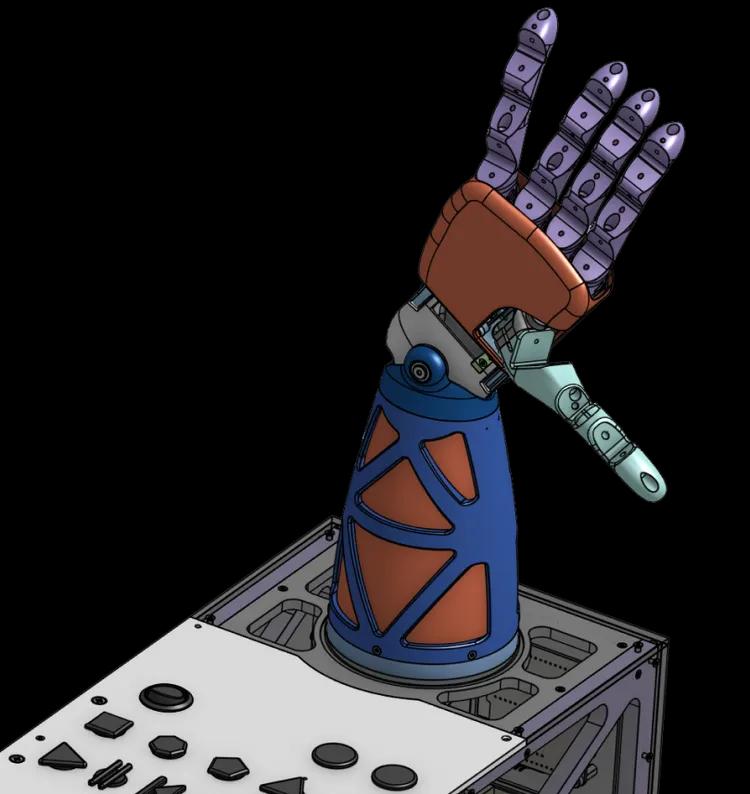

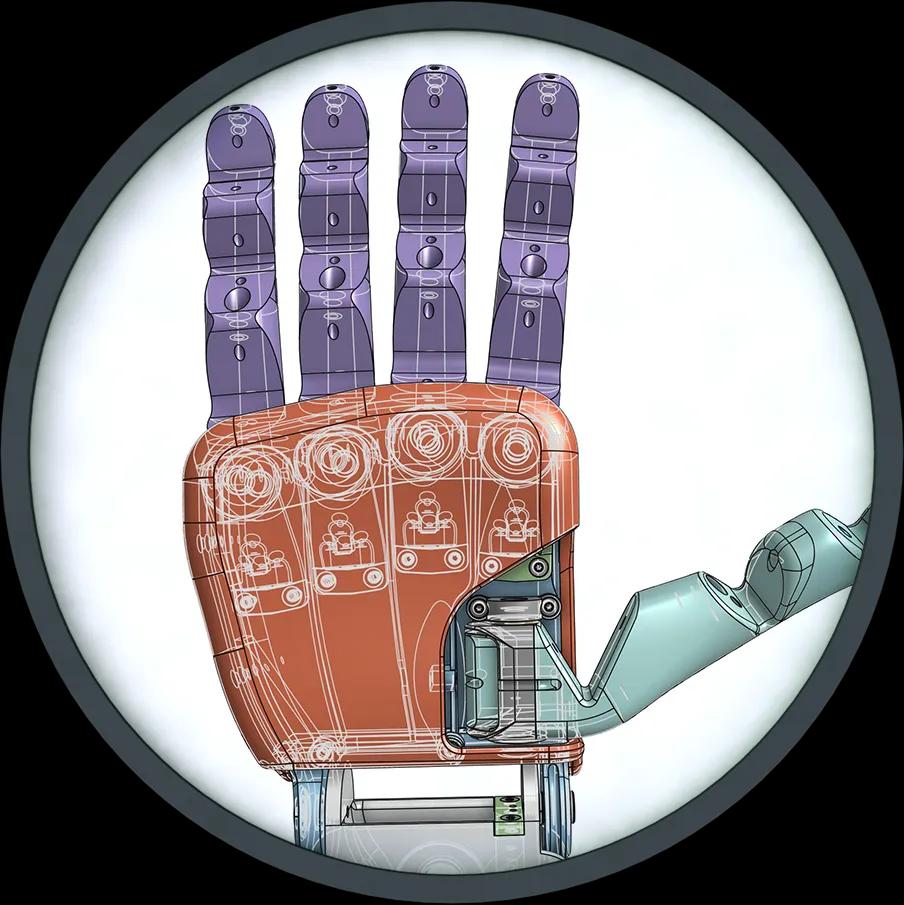

TATUM ROBOTICS

Tatum Robotics is revolutionizing communication for the deafblind community by creating the first tactile sign language interpreter. The design team was hesitant about their previous CAD tool for security reasons. When they sent a file to a partner, it would be gone and out of their reach. However, with Onshape, Tatum is now able to easily share a design with someone and withdraw access just as quickly, enabling quicker and safer design feedback from the community.

SCEWO

Based in Switzerland, Scewo revolutionized the wheelchair industry with the first and only electric stair climbing wheelchair, ‘BRO.’ Onshape provided relief for their IT teams, as they no longer required software downloads, installations and license codes. They could also access the platform on any web browser and device, including on Mac, PC, Chromebooks, or even Linux computers. In addition, Onshape’s modern user interface, ease of use, and integrated PDM enabled Scewo to iterate on their design collaboratively and bring their product to market faster.

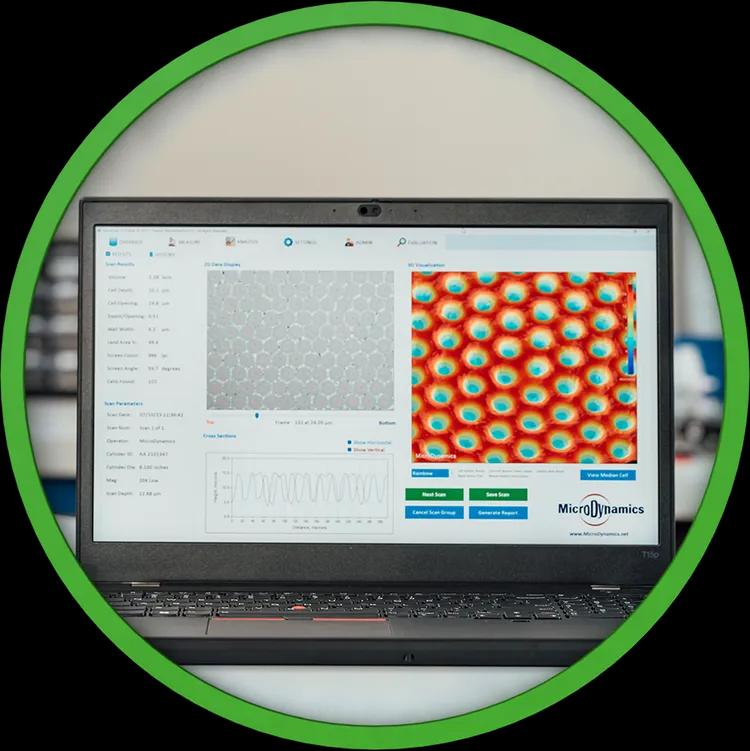

MICRODYNAMICS

MicroDynamics is the leading provider of high-precision quality control instruments for the Flexo Printing Industry. The team switched to Onshape because of the cloud-native architecture which allows for remote work on any device and the built-in PDM which saves them about 20 hours. Onshape’s advanced collaboration tools also foster effective communication during the design process. According to MicroDynamics, “the productivity increase is like adding another engineering resource to the team.”

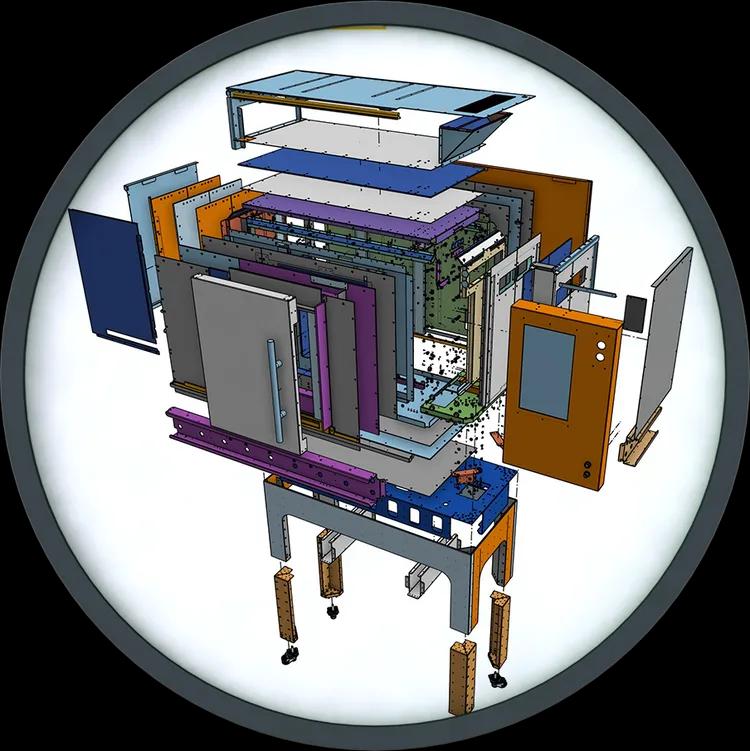

LUMAFIELD

Lumafield specializes in industrial CT scanners for visualizing and analyzing features on the inside and outside of parts and assemblies, closing the loop between design and manufacturing. The team faced hurdles with legacy desktop CAD software’s collaboration, version control, and license management. Onshape made onboarding new engineers quicker with the ability to easily send new account invitations when a teammate joins. In addition, the cloud-native platform helped the team with hybrid work.

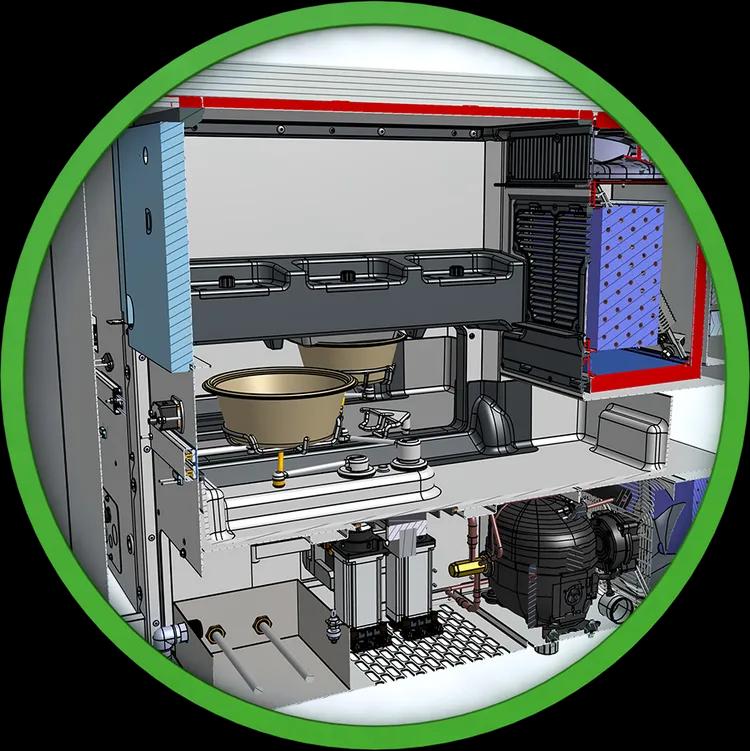

HYPHEN TECHNOLOGIES

Hyphen Technologies created an automated makeline that optimizes food production. After switching to Onshape from SOLIDWORKS, the team has eliminated file disorganization, enabled easy experimentation through branch and merge, and fostered seamless collaboration among their teams. This enables a more agile development process, with quicker iterations to problem-solve the unique challenges of dispenser designs and ingredient permutations.

Onshape Product Features

Cloud-native

Unlike other “cloud” CAD solutions that were adapted to fit in a cloud environment, Onshape was built for the cloud. It is stable and reliable, eliminating the time loss associated with CAD crashes - which studies show can be over 7 hours per week. Onshape is accessible through any web-enabled device or through the mobile app for iOS and Android devices.

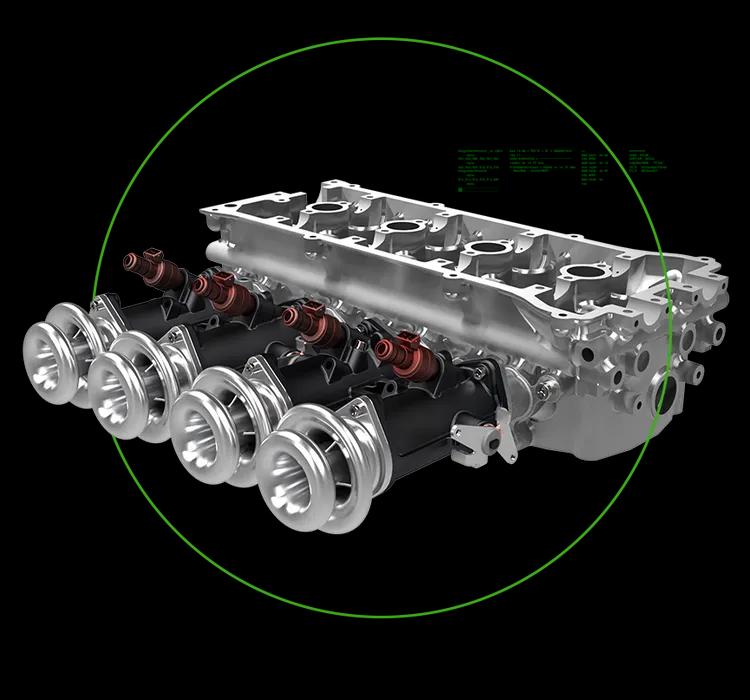

Professional-Grade CAD

Onshape delivers 3D CAD online, supporting solid modeling, surfacing, sheet metal design, and more in your browser. Designing in Onshape is easy and intuitive. For example, assembly mate connectors can be built in far fewer steps than competitive solutions like SOLIDWORKS. During revision edits, there is also no risk of breaking. You can also create custom CAD features (or tools) using Onshape's FeatureScript.

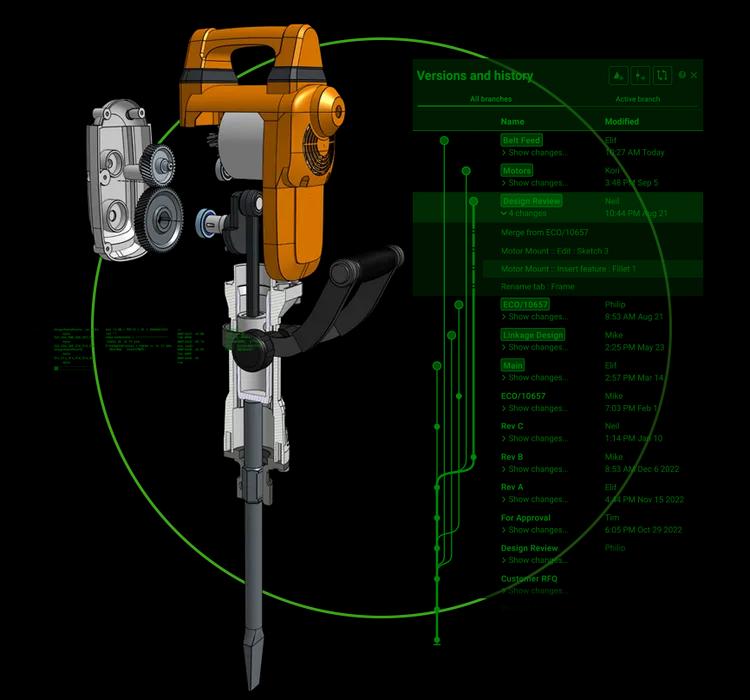

PDM

Onshape's built-in Product Data Management (PDM) is a hassle-free way to centralize, store, search, and manage your data without the need for an expensive PDM system. Designed using a database architecture (instead of files), Onshape’s unique approach to PDM increases visibility while ensuring traceability of every action taken during the design process. This eliminates version control headaches while ensuring there's only one single-source of design truth without having to implement file check-in/check-out protocols.

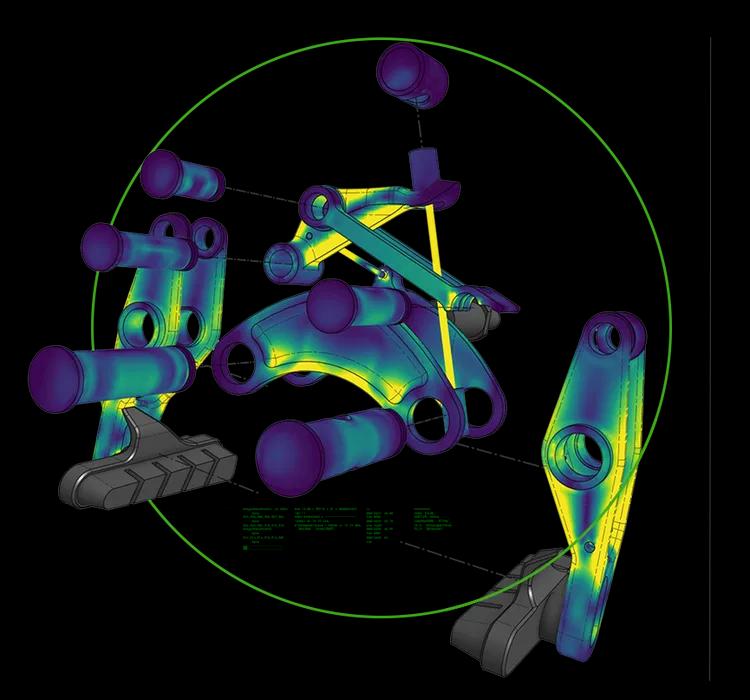

Simulation

Onshape Simulation is the easiest and fastest way to examine meaningful structural analysis results such as stress, displacement and natural frequencies, as you create and iterate in the Onshape design environment. With simulation built into Onshape’s cloud-native architecture, you can build better quality products faster with mechanical feedback that stays in sync with your assembly throughout the product development process.

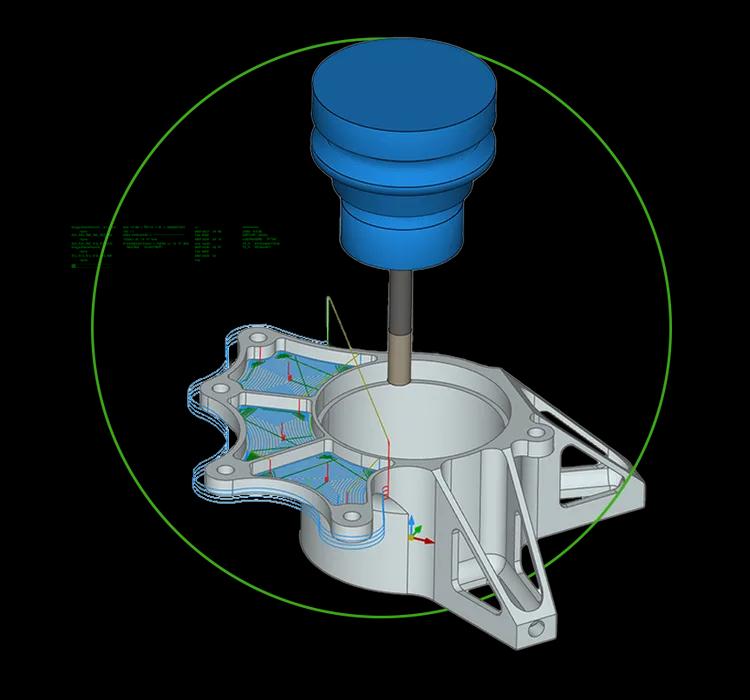

CAM

Computer-aided Manufacturing (CAM) Studio is used to generate, visualize, and simulate your manufacturing processes for 2.5 to 5-Axis simultaneous CNC machining operations. It is the industry's first cloud-native CAD, CAM, and PDM combination that helps users version CAM strategies alongside their models. CAM is currently available for early visibility customers.

Render

Create professional dynamic images of your Onshape models with Render Studio. This capability delivers photorealistic rendering of CAD models on any supported web browser, without a high-end graphics processing unit (GPU) or dedicated workstation.

Join Onshape's Community & Design What's Next Today

See how Onshape can elevate your design process with the Onshape Discovery Program. Through this program, qualified CAD users can access the Professional plan free for up to six months. If you're transitioning from SOLIDWORKS, explore the Migration Station for tools, options, and strategies related to importing your files into Onshape. The future of product design awaits.