Onshape’s part and assembly configuration features make it easy for product development teams to quickly design families of products that differ in size, color, materials and many other variables. Designers just select from dropdown menus of various configuration options and the CAD model automatically updates. Although the convenience and speed of Onshape’s configurations are usually associated with improving the design process, these same user-friendly benefits can also give customers more choice and control over their purchases.

Michigan-based Fairlane Products, a leading manufacturer of standard components used in machine tool workholding, specialty fastening and material handling, has used Onshape to build a customer-friendly web app that allows users to design and buy custom robot gripper fingers in minutes.

Gripper fingers, attached to a module at the end of a robotic arm, function to pick up, move or position objects at an automated workstation. Fairlane’s intuitive GripShape interface, powered by Onshape, requires no CAD experience to design one-of-a-kind robotic grippers using standard components and custom fingers determined by the shape of the workpiece. The design can either be made or assembled by Fairlane using additive manufacturing and CNC machining – or the user can choose to just purchase the CAD model to manufacture at their own facility or with another vendor.

“The biggest benefit of using GripShape is that it makes implementing automation easier,” says Justin Gordon, CEO of Fairlane Products. “We have simplified the design process so that both engineers and non-technical users can arrive at a fully customized solution for their application while reducing the design time significantly. We were able to do this by building in a lot of the logic needed for the gripping application, so the user doesn’t have to start from scratch.”

“Our configurator is unlike any others out there on the market,” he adds. “The power of the application exists in our logic layer that takes into account every parameter the user has control over and directly updates the CAD model instead of stretching or skewing the client-side render. This gives full control over the CAD model at the sketch level.”

GripShape’s ecommerce platform uses Onshape’s powerful API system, configurations and derived components to give the user the same intuitive feel as Onshape’s user interface.

Improving the Sales Process With Onshape’s Configurations

Powered by Onshape, the GripShape configurator is an intuitive application that is changing how custom robot gripper fingers are designed and purchased. The configurator is easy to use and requires no CAD experience.

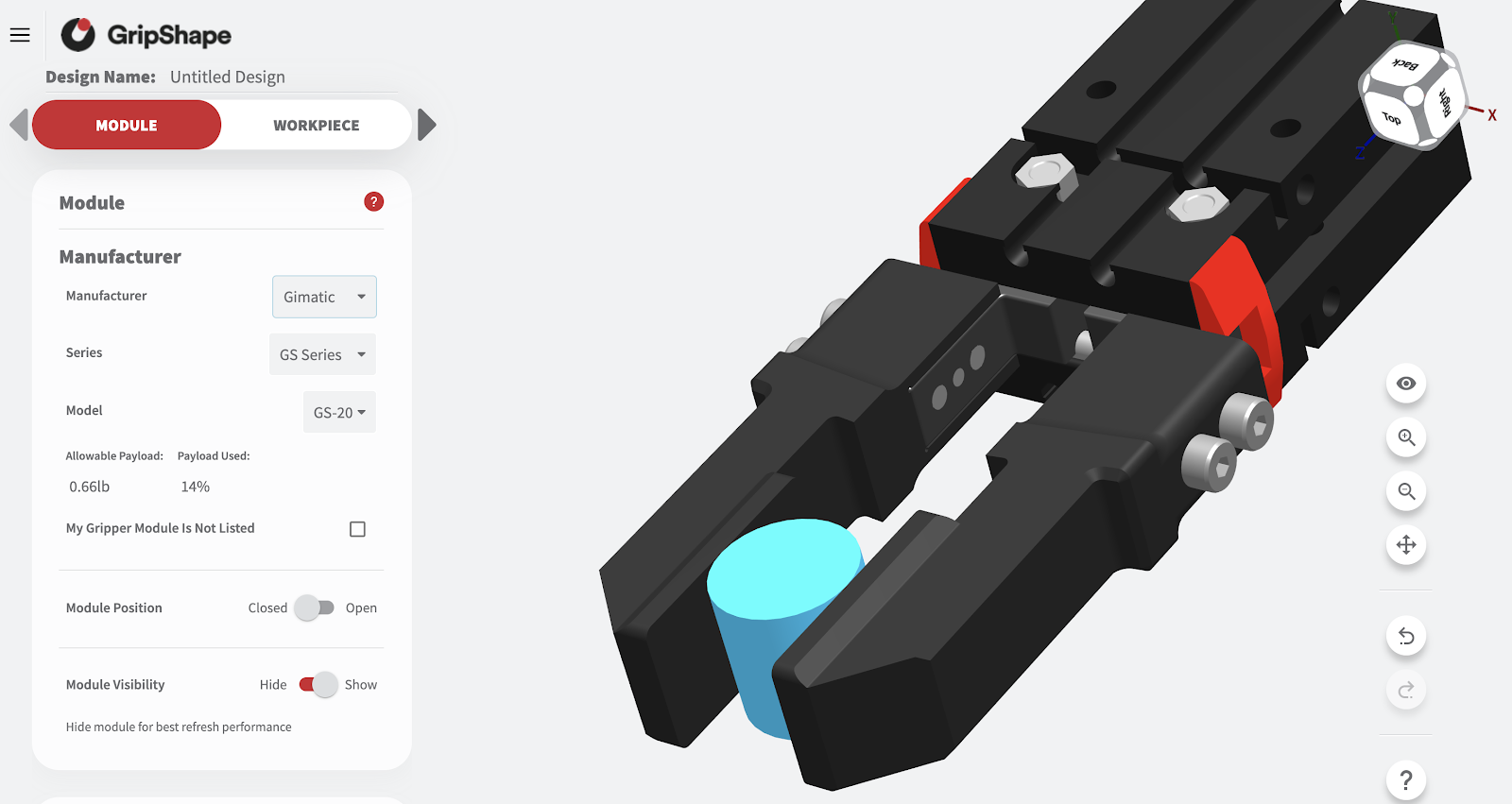

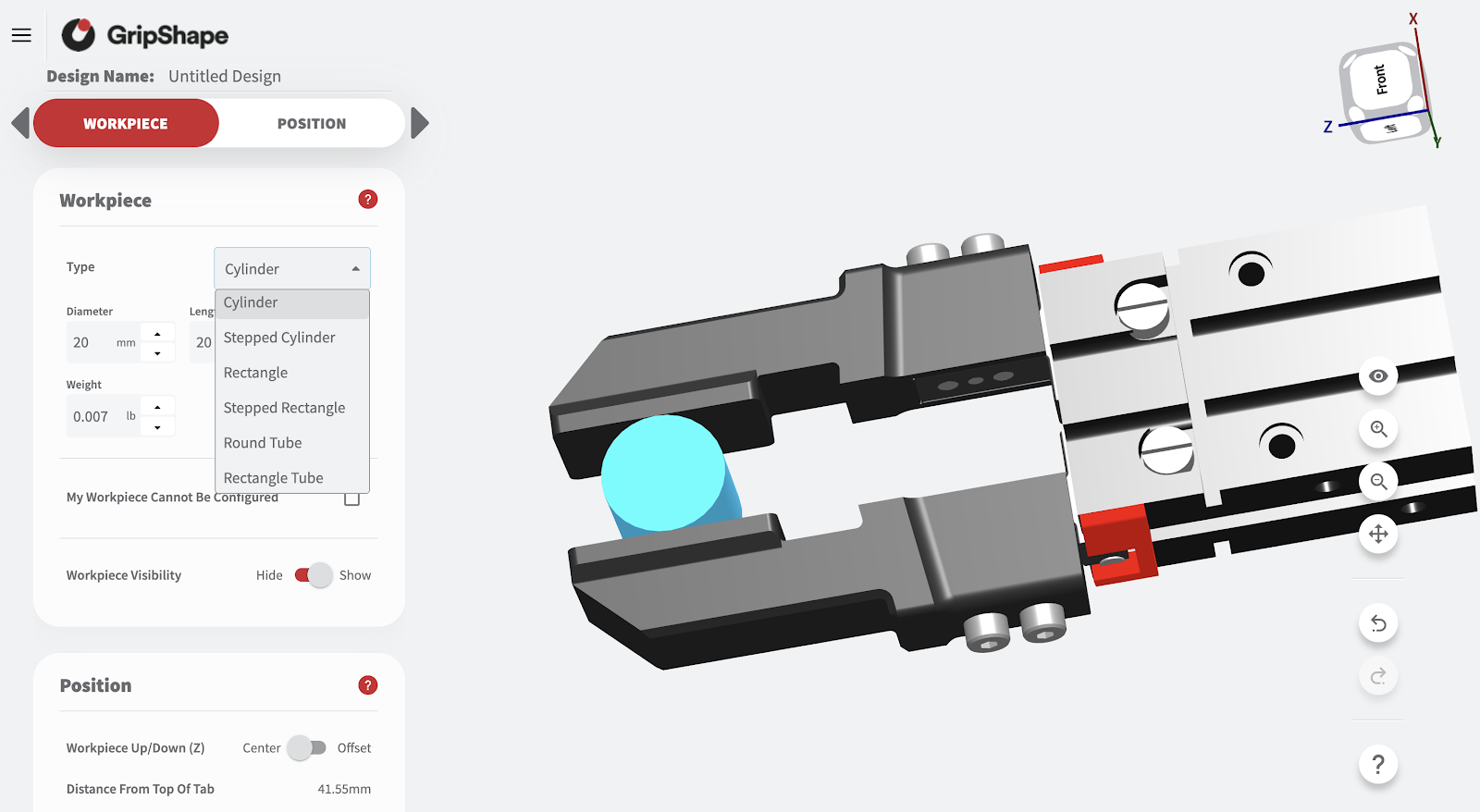

With GripShape, customers start by selecting a gripper module from a list of manufacturers. Then they choose a representative workpiece and adjust its size.

From start to finish, designing and ordering custom robotic gripper fingers with the GripShape configurator takes about 10 minutes – compared to hours of an engineer’s design time.

Next, they adjust the finger length, grip width, grasp type and more.

As the design is fine-tuned, users can refresh the 3D model to see their changes instantly. If the gripper fingers require revisions or other design optimization, users may request a quote in the purchasing section of the configurator and complete the form.

Once complete, users can download Parasolid CAD models to review the designs in their own CAD projects. If desired, the Fairlane team will review the design, provide basic feedback and provide a price quote for the requested revisions.

The Fundamental Advantage of Cloud-Based Configurators

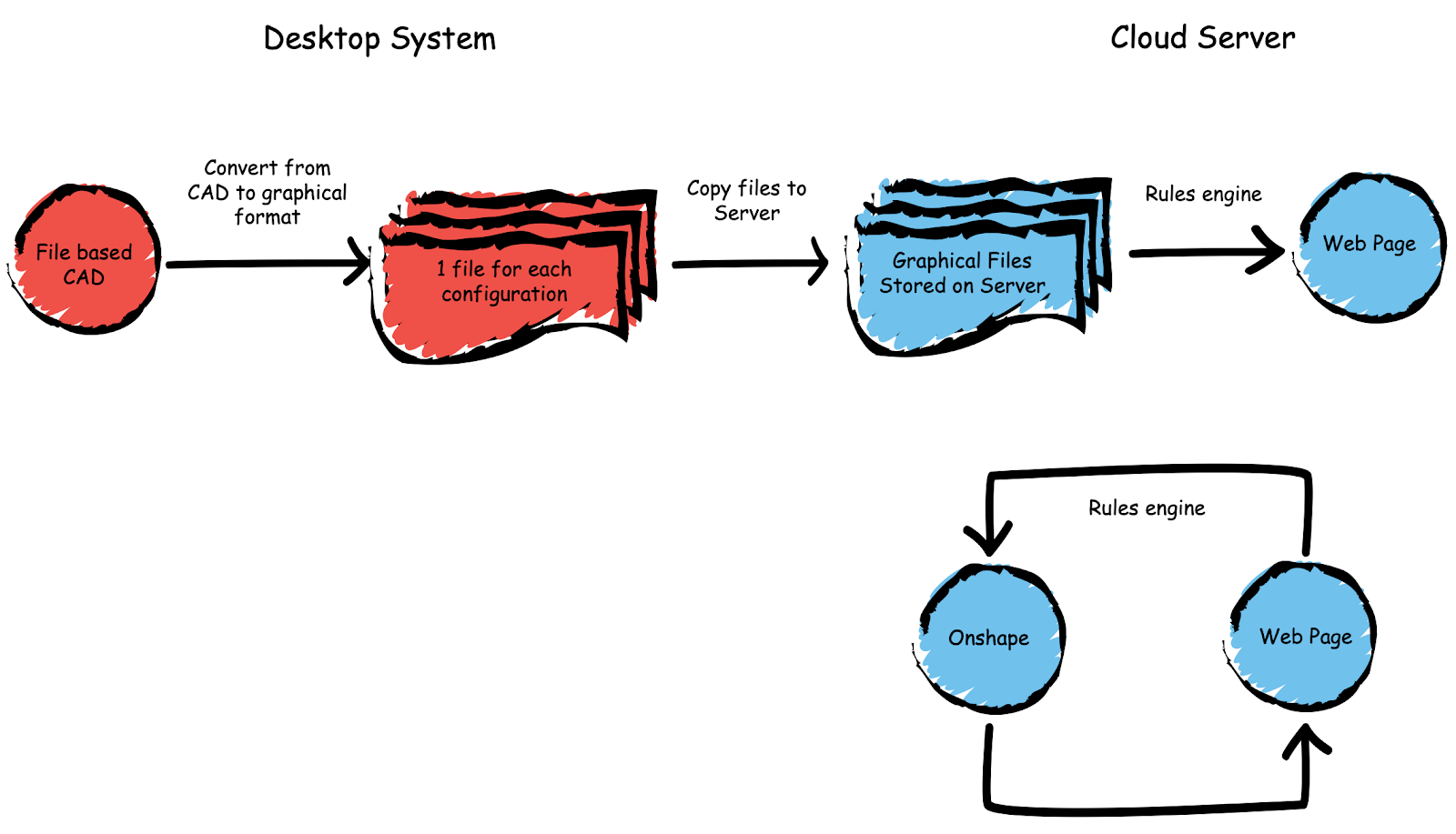

In the past, if a company wanted to build an online configurator, the data would need to be extracted into a file format. Typically, this would require a discrete number of variations to be generated and stored as individual files. The data would be disconnected from the source CAD data.

Once created, the data would then need to be copied from the desktop system to a server. This itself is a complicated process, sometimes involving multiple software products. Once the data has been copied to the server, additional software is required to display, control and build the presentation on the website.

Online configurators based on cloud-native Onshape reduce many potential points of failure compared to desktop file-based solutions. With ecommerce platforms like GripShape, the customer has a richer, more accurate experience – and the manufacturer is assured that their engineering data matches their online configurator.

GripShape Provides Parasolid CAD Models Ready to Manufacture

As GripShape users switch out or modify components, the price estimate at the bottom of the screen instantly updates when refreshing the CAD model.

Gordon stresses that when a custom robot gripper is designed on his company website, customers are not just seeing a visual representation of the final product.

“What we deliver in the end is a true Parasolid CAD model that can be used in any type of CAM system for CNC machining, or it's ready to be sliced and then 3D-printed,” Gordon adds. “There’s no other configurator out there that can do this.”