The Challenge

HoverAid is an international charity using hovercraft to deliver aid to remote communities in underdeveloped parts of the world. Since 2006, HoverAid has set up a permanent base in Madagascar where its two hovercraft navigate the country’s shallow river systems to bring much needed medical care and resources to isolated communities. Realizing that it needed new crafts, as the current ones were over 30 years old, the challenge was that there was no digital models or much information about these crafts other than a folder of printed 2D drawings and some old jigs and fixtures. With the current single seat of file-based AutoCAD not being up to the task, the team wanted a CAD system that would enable them to more easily collaborate and together assemble a single version of the truth. Being a charity, HoverAid was drawn to the fact that Onshape was cloud-native and device agnostic.

Results

- HoverAid’s design team, some of whom had no previous CAD experience, were able to effectively learn how to use Onshape from the online training materials and support.

- HoverAid estimates it has saved 6 to 12 months of development time through the use of Onshape’s real-time collaboration tools that has enabled its distributed team to work simultaneously over the cloud without the use of any special hardware.

- Following the success of this first design, HoverAid plans to use Onshape to model the complex shape of the skirt, which is currently approximated, to add even further efficiencies to future models.

Being a charity that relies only on fundraising and grants, and is run predominantly by volunteers, we have also been able to save money through the overall effectiveness that we’ve gained from using Onshape.’’

Some underdeveloped areas of the world communities are so remote that they are practically unreachable.

International charity HoverAid has made it its mission to bring aid to these isolated communities by means of hovercraft.

While HoverAid officially became a charity in 1991, its origins date back to 1969 when humanitarian air operator Mission Aviation Fellowship (MAF) designed a hovercraft to negotiate the shallow waters of Lake Chad in central Africa. Since then this River Rover design has been used to deliver aid to isolated communities in various locations across the world, including Nepal, Papua New Guinea, Nicaragua, Mozambique, Zambia, and Malawi.

In 2006, MAF invited HoverAid to Madagascar, an island country off the east coast of southern Africa. Regularly hit by cyclones and flooding, many of the 25 million people living alongside the country’s vast river systems are often completely cut off with dirt roads washed away and the rivers too shallow for boats to navigate.

Setting up a permanent base in Madagascar’s capital city Antananarivo, HoverAid’s team consists of about 20 who are located either in Antananarivo itself or in one of the charity’s international offices based in the UK, the Netherlands and France. These offices consist predominantly of full and part-time volunteers and fundraisers.

“The main thrust of what we do at HoverAid is bring teams of medics from the capital Antananarivo to rural communities. They set up camp for a couple of weeks and run community health clinics providing major and minor surgery. Previously it would have taken them three days to walk or two days in a canoe but with the hovercraft we can get them there in under three hours,” says Chris Evans, HoverAid’s Hovercraft Project Manager who is based in the UK.

A hovercraft fit for purpose

Hovercraft are unique in their ability to easily navigate terrain such as mudflats, swamps, ice, rapids, and shallow waterways. A lift fan creates a cushion of air that is trapped underneath the hovercraft’s flexible ‘skirt’. The slightly higher air pressure within the skirt enables the craft to lift off and glide above the surface with the use of a propeller or thrust fan.

“Hovercraft are not the most maneuverable. It’s a bit like pushing a shopping trolley really fast around the supermarket. However, the HoverAid craft are designed to bank into corners making them that much more maneuverable, which is crucial when navigating the river systems in Madagascar,” explains Evans.

Evans, who works as an engineering director for a clean tech energy startup, volunteers for HoverAid, helping to design and build the next generation River Rover. “I often joke that this is my mid-life crisis project in someone else’s shed,” he says.

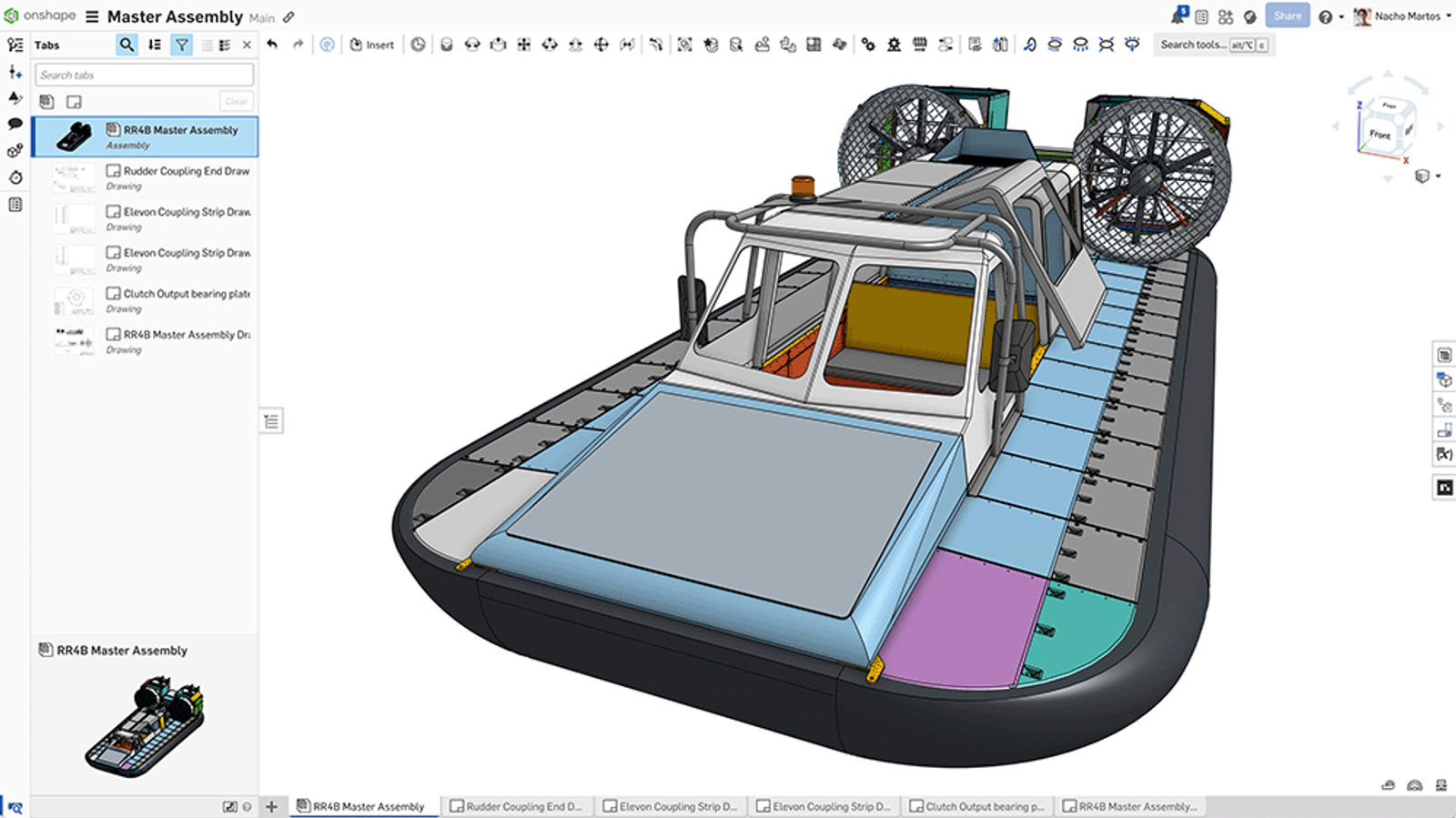

The shed in question is actually a large barn on a farm in Sussex, UK. Evans relies on Onshape - a cloud-native CAD and PDM platform with built-in collaboration and simulation tools - to design the craft and then with a team of volunteers they build it using hand tools and basic machining.

Onshape delivers a single source of truth

HoverAid’s two hovercraft currently in use in Madagascar were built over 30 years ago. To build a new one based on this tried and tested design proved challenging as there were no digital models of this design and the information available was quite scant.

“I have folders of printed 2D drawings that have been annotated with pencil. There are also some old jigs and fixtures that were used to make the craft but often things were tweaked and repaired in the field. I call it engineering archaeology - using the information we have to assemble a single version of the truth,” says Evans.

It is quite an undertaking so why not simply buy a hovercraft? As Evans describes, the HoverAid crafts have very specific requirements. These include high maneuverability as well as being able to operate in a hot climate and at high altitudes. But most crucially it has to be a simple construction that can easily be maintained in the field.

“It is like a massive Meccano set made from fiberglass and aluminum that’s all bolted together. There's nothing on it that you can't either repair or replace using fairly simple hand tools,” he says.

To capture all the various parts and assemblies in a 3D model required the use of a CAD tool. Previously, HoverAid’s Chief Development and Technical Officer, Andy Mayo, based in the UK’s head office in Cambridge, was attempting to do this using an old version of file-based AutoCAD.

“This was not the right tool to use as he was struggling to reassemble everything. He also couldn’t collaborate with other members of HoverAid’s distributed design team including myself, a designer in Northern Ireland, and the head mechanic in Madagascar,” says Evans.

Having heard about Onshape through his ‘day’ job, Evans was immediately attracted to it being cloud-based and device agnostic. Additionally, he was also drawn to the free version meaning he could experiment before making any commitment.

Even with no previous experience of using mechanical engineering tools like CAD as he has a controls engineering background, following a few weeks of experimentation and making use of Onshape’s online training materials and support, Evans managed to effectively teach himself how to use it.

“The fact that by the end of the trial period I was able to do sensible things proves that it is an intuitive tool for even users like myself who are unfamiliar with CAD,” says Evans

Onshape effectively brings distributed teams together

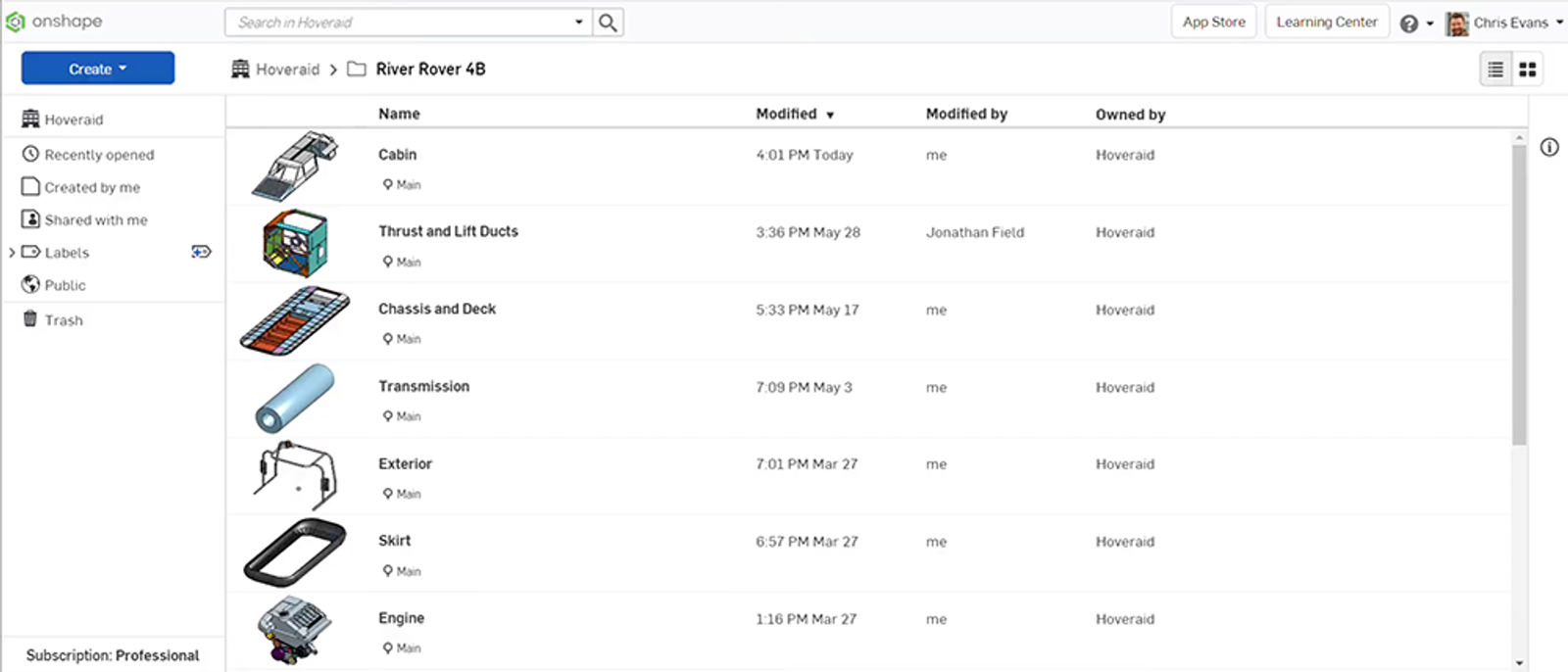

The first task for Evans and the team was to capture the design before making any improvements. One such improvement was integrating a more powerful BMW diesel engine into the craft. Following a 3D scan of the engine, for which HoverAid partnered with UK engineering consultancy Ricardo, the engine was imported into Onshape.

During this process Evans valued having a single source of truth with Onshape’s built-in PDM with automatic version control as well the branching and merging functionality. As he says, “It means that our distributed team can work simultaneously on different parts in the same assemblies. So while Andy went off on his own branch looking at how to mount the engine, the rest of us could still work on all the bits around the engine. Once he’d completed it, we then merged that branch back into the live version.”

Whereas collaboration amongst the team was impossible before, now the team were able to work very effectively together. “At times we were having design reviews with members in five different locations, some of whom were using a 4G mobile phone connection. I can't overstate how effective that's been without the need for any specialty hardware, just any web-enabled device.

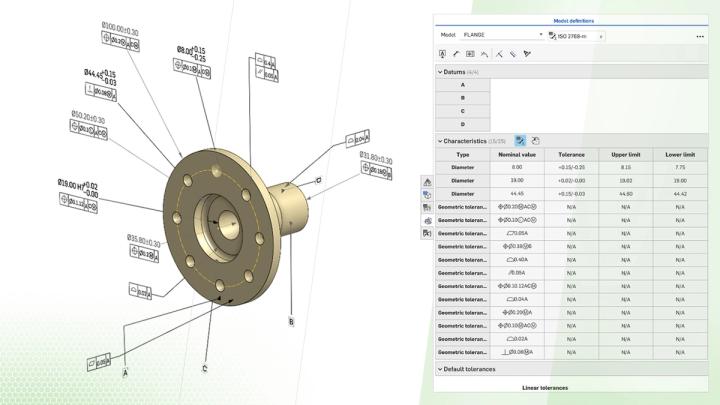

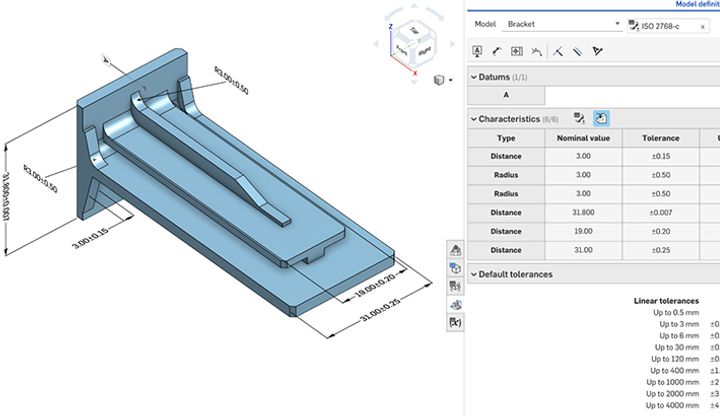

Using connected apps to improve the design

HoverAid also made use of connected apps available in the Onshape App Store, including the SimScale simulation cloud app to improve the efficiency of the hovercraft’s air flow and lift system. “We extracted simplified models of the air volumes from Onshape into SimScale and based on the resulting CFD analysis we made various tweaks. The result was that we were able to take about 80% of the losses out of the lift air system in terms of how the air is moved from the thrust fan down to the skirt. That's massive in terms of the impact it has on range and payload,” says Evans.

Once all the improvements were made to the design and it was fully captured in Onshape, the build process could begin. This stage was reached far quicker than if the team had continued using a single license of AutoCAD that only one user had access to. According to Evans, 6 to 12 months have been saved through the use of Onshape.

“Being a charity that relies only on fundraising and grants, and is run predominantly by volunteers, we have also been able to save money through the overall effectiveness that we’ve gained from using Onshape,” says Evans.

Future gains with limited resource

HoverAid plans to ship this new craft to Madagascar once the build is complete in the next few months. According to Evans, it will hopefully be the first of a few to be built because now that the design is in parametric form, any future improvements will be much easier to make.

He is already looking forward to using Onshape to model the complex shape of the skirt, which is currently approximated, to add even further efficiencies to future models. “It’s inspiring to be involved in a charity like HoverAid that does a lot with very limited resources,” says Evans. “We value Onshape’s support in this project and what the tool has enabled us to do.”