1:32

Today’s tech tip focuses on the newly released Composite Parts feature in Onshape. This new functionality allows you to define a part as a composition of parts, surfaces, curves, and points. A composite part is treated as a single part throughout Onshape, including both in the Bill of Materials and when using Release Management. Let’s take a look.

Let’s walk through a simple but common scenario – How to import a subassembly that contains multiple parts but recognize them as a single part. For this example, we’ll use a caster wheel consisting of five distinct parts. There are two ways to create a composite part of this wheel:

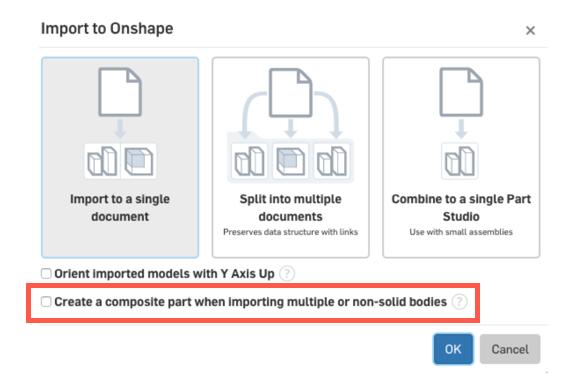

1. Upon import (either at the Documents page or from within a Document) as shown in the following image:

Or:

2. From within a Document by clicking the Composite Part icon in the toolbar.

The above video shows how to select the parts you want to create a composite part from. You will notice that what was originally a collection of parts is now one composite part in the parts list. Note that the option “Closed” was selected. This effectively removes all of the individual parts so that only the composite part remains.

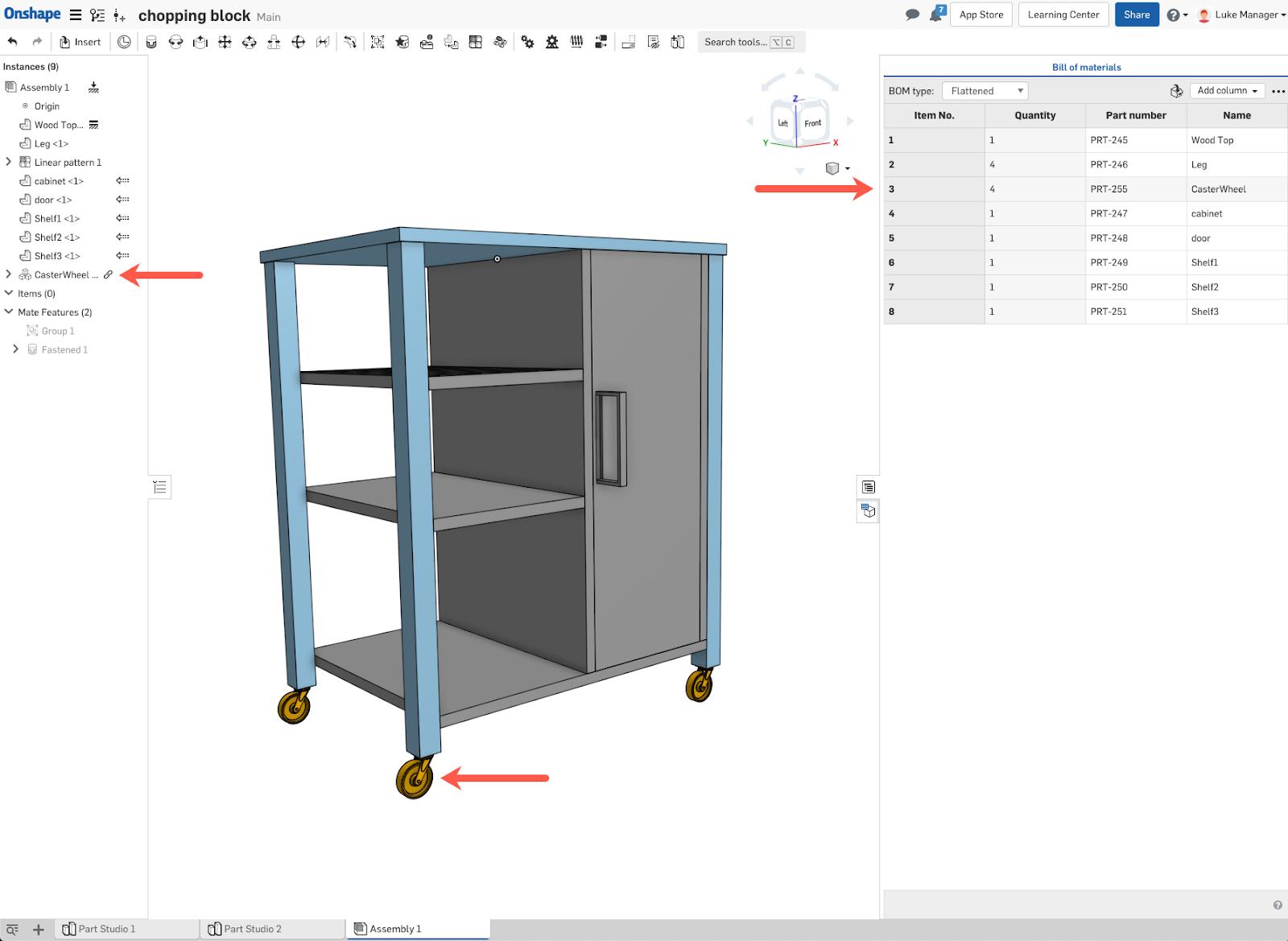

These composite parts are great for inserting into Onshape Assemblies and cleaning up the BOM. Now, let’s take this caster wheel and insert it into a chopping block assembly.

The above screenshot shows the caster wheel inserted into the assembly and instanced four times using the Linear Pattern tool. In the BOM, the caster wheel part appears as one entry with a quantity of four.

Finally, composite parts can also be released as one object. This makes it easier to control, produces fewer objects to track during revision processes, and requires fewer mouse miles.

Interested in learning more? Check out the video above.

Latest Content

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more