Formlabs has discovered that the key to better hardware is... better software.

That one change: Onshape and AWS

Because the solution tracks every design change, team members can instantly revert to earlier designs if they wish. Executives overseeing multiple design projects can get up-to-date status reports without waiting for periodic design review meetings.

This real-time collaboration-from-anywhere capability is possible thanks in part to the highly available, highly secure AWS services that address potential risks associated with broader data sharing. Those factors include AWS secure data centers, secure high-speed networking, and additional layered services, such as Virtual Private Clouds, Key Management Service and encryption. Formlabs gets the benefit of these security factors without having to deploy and manage them in its own environment.

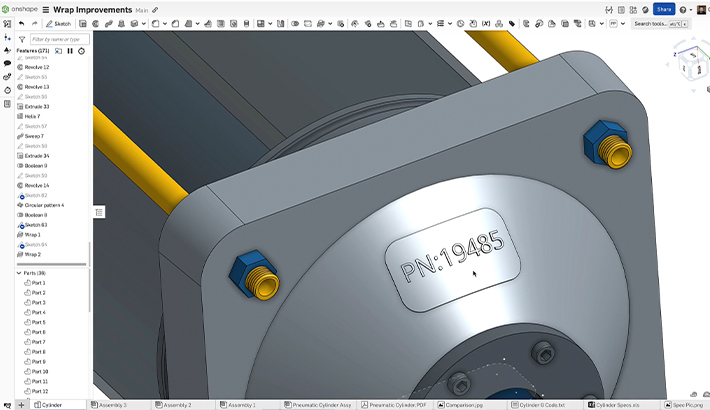

A Formlabs printer as modeled in Onshape.

Real-time collaboration from anywhere

For example, when Lebovitz traveled recently to one of Formlabs’ outside manufacturers in Europe, he edited CAD files on the fly and shared the data with the manufacturer without needing to be on his company’s network—and with designers back in Boston watching the changes in real time. When a colleague wants to see the most recent progress on a current project, Lebovitz simply sends them a link.

Lebovitz and his colleagues also now have more confidence in their work because of Onshape’s reliability. “We catch and fix CAD mistakes more quickly, reducing our stress and increasing our confidence,” he says. “We’ve greatly reduced the hassle and expense of receiving a manufactured part only to find that the part was manufactured based on out-of-date CAD files. I find myself doing much less re-ordering and reworking.”

Eliminating the challenges of traditional CAD

The IT overhead for the solution was high and—as Formlabs continued to grow—getting higher, as the company had to manage and update servers, ensure the integrity of production data and backups, and configure desktops as new employees were onboarded. System updates needed to be on everyone’s machine at the same time to facilitate collaboration, and some annual updates were delayed or skipped because implementing them would slow product development cycles. And when servers went down, designers and others couldn’t access their data.

“We were at the whim of the servers,” says Lebovitz. “That’s not the case with Onshape and AWS.”

Quite the reverse. “It’s comforting to know that Onshape runs on AWS,” says Lebovitz. “AWS has always been reliable for us. It gives me a high level of confidence in what is for us a truly mission-critical solution.”

About Formlabs