06:60

Modern factory automation has revolutionized manufacturing, packaging, and distribution processes. For consumers, this means higher quality and consistency in products. For manufacturers, it enables mass production at unprecedented speeds while maintaining quality. However, machine builders face intense competition and must continually innovate to meet demanding requirements.

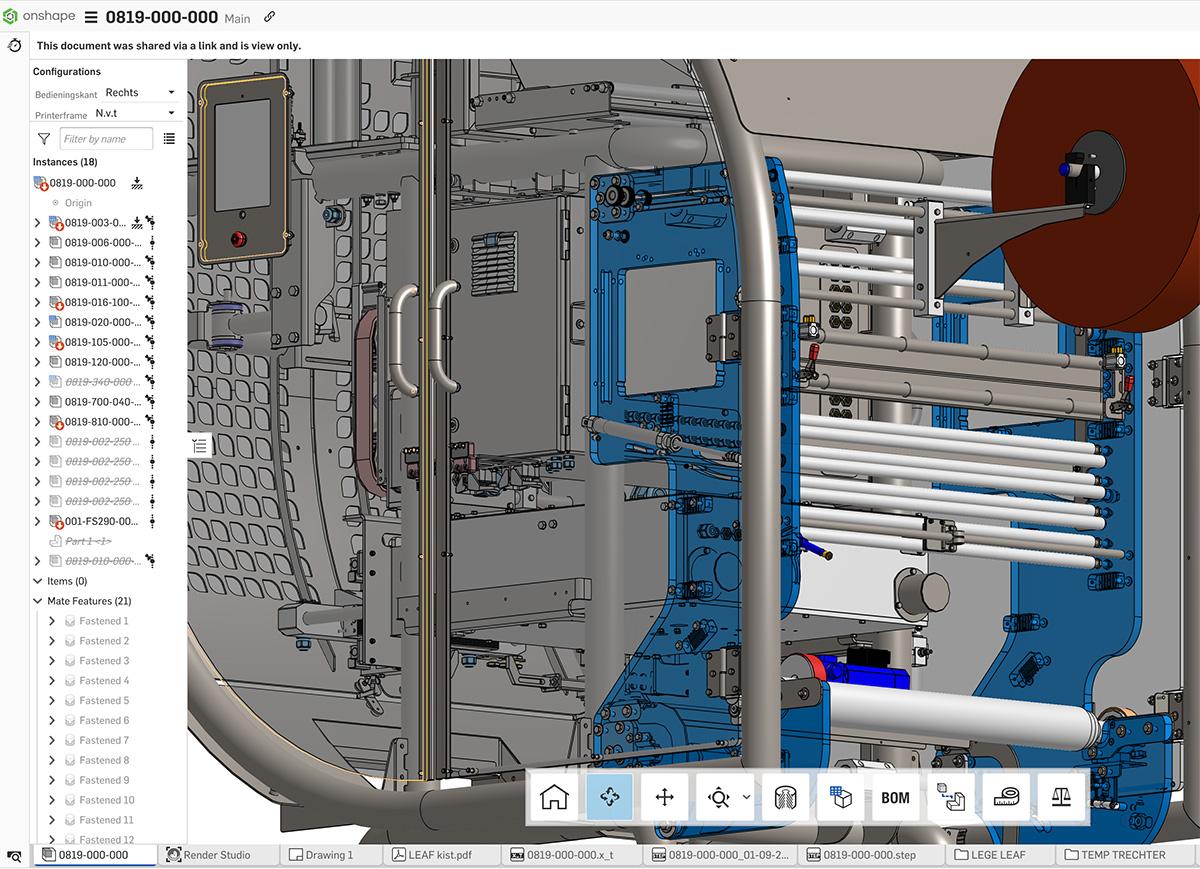

Let’s explore key machine design challenges and how modern CAD systems for machine design, such as PTC’s Onshape, can help overcome them.

Key Challenges in Machine Design

Speed and Accuracy in Machine Design

Machine designers constantly grapple with the balance between speed and accuracy. While faster machines are often seen as more desirable, they come with increased risks of breakdowns and quality issues.

The challenge lies in creating designs that optimize both speed and precision without compromising reliability. Additionally, managing design changes across teams can be complex. As multiple engineers work on different aspects of a machine, ensuring that all modifications are properly communicated and integrated becomes crucial to avoid errors and mismatched components.

Reliability in Machine Design

Reliability is paramount in machine design, yet it often conflicts with demands for rapid delivery and cutting-edge features. Customers expect machines to perform consistently over long periods, with minimal downtime and maintenance requirements.

This expectation pressures designers to create robust, durable systems while still meeting tight deadlines. Moreover, the ability to measure and improve Overall Equipment Effectiveness (OEE) has become increasingly important. Designers must not only create reliable machines but also incorporate features that allow for easy monitoring and optimization of performance over time.

DOWNLOAD eBOOK: Modern CAD for Machine Design

Flexibility in Machine Design

The modern manufacturing environment demands flexible machines capable of handling multiple products or adapting to changing production needs. Designing such versatile equipment presents significant challenges.

Engineers must consider how to incorporate adaptability without overly complicating the machine's structure or control systems. This often involves a delicate balance between mechanical flexibility and software-driven adaptability. Managing the increased complexity that comes with flexible designs, while still ensuring ease of use and maintenance, requires innovative thinking and careful planning.

Modular Machine Design

Modular design approaches offer numerous benefits, including faster development times, easier maintenance, and greater flexibility. However, implementing modularity in machine design comes with its own set of challenges. Designers must carefully consider how to create standardized interfaces between modules while still allowing for customization.

There's also the challenge of balancing the benefits of modularity with potential increases in machine footprint or complexity. Ensuring that modular components can be easily assembled, disassembled, and interchanged without compromising overall machine performance requires meticulous planning and innovative design solutions.

Communication in Machine Design

Effective communication is critical throughout the machine design process. Clearly defining and understanding customer requirements and expectations from the outset is essential but often challenging.

As designs progress, sharing detailed information across different teams, and potentially different CAD systems, can lead to misunderstandings or data loss. Managing feedback and design updates efficiently becomes increasingly complex as more stakeholders become involved. Designers need effective tools and processes to ensure that all parties have access to the latest, most accurate information and that design intent is clearly communicated at every stage.

Collaboration in Machine Design

Machine design often involves multiple team members, sometimes spread across different locations or even different organizations. Enabling effective collaboration in this environment is a significant challenge.

Traditional file-based systems can lead to version control issues, with team members potentially working on outdated designs. Coordinating input from various stakeholders, including customers and suppliers, adds another layer of complexity. Designers need solutions that allow for real-time collaboration, seamless data sharing, and efficient integration of feedback from all parties involved in the design process.

How GKS Machinery Overcame Machine Design Challenges

GKS Packaging, based in the Netherlands, specializes in flexible packaging solutions for businesses of all sizes. Their product line includes vertical form, fill, and seal machines, along with custom-designed weighing systems, dosing systems, and conveyor belts. The company faced significant challenges with its previous CAD software, particularly when multiple team members needed to work on the same design.

Ivo Geukes, owner of GKS Packaging, described the frustrations they experienced. When using their old system, managing multiple users working on a single design often resulted in confusion and inefficiency. The team frequently encountered issues with broken assemblies, leading to time-consuming rework. Making a simple change, such as enlarging a hole in one part, could cause unexpected changes throughout the entire assembly, turning the left side of the screen red with errors.

Data management was another major pain point for GKS. Their previous PDM system was cumbersome and often hindered rather than helped their workflow. If one team member had a part open, others could only access it in read-only mode, creating bottlenecks in the design process. Keeping track of which parts were already in the assembly and which ones still needed to be produced was a constant challenge.

The switch to Onshape – a modern, cloud-native CAD system – transformed GKS's design process. Geukes particularly appreciates the ability to branch designs and create versions, noting that it’s now much harder to accidentally disrupt an assembly. The simultaneous editing feature has proven invaluable when designing new packaging systems. Now, when one team member makes a change, everyone else sees it instantly, greatly improving collaboration and reducing errors.

This transition to a more advanced CAD solution has allowed GKS to focus more on innovation and less on managing software limitations. The improved workflow has enabled them to design more efficiently, respond more quickly to customer needs, and ultimately deliver better packaging solutions to their clients.

FULL CASE STUDY: GKS Packaging Creates Eco-Friendly Bagging Machines for Supermarket Produce

Onshape: A Modern CAD System for Machine Design

As machine design challenges continue to evolve, embracing cloud-native CAD systems with built-in PDM becomes crucial for staying competitive. Onshape for machine design offers a comprehensive solution that addresses key pain points in the design process:

- Cloud-Native Architecture: Eliminates file management issues and ensures all team members work with the latest data.

- Version Control and Branching: Allows easy exploration of design alternatives without affecting the main design.

- Real-Time Collaboration: Enables simultaneous editing and instant updates for all team members.

- Built-in Data Management: Simplifies the tracking of design changes and iterations.

- Advanced Modular Design Tools: Supports the creation of configurable parts and assemblies for modular machine design.

- Seamless Communication: Facilitates easy sharing and commenting on designs with all stakeholders.

By leveraging these advanced features, machine designers can focus on innovation and problem-solving rather than grappling with software limitations. As demonstrated by companies like GKS Packaging, the switch to a modern, cloud-native CAD system can be a game-changer in overcoming machine design challenges and delivering superior products to market faster.

In an industry where efficiency and innovation are paramount, adopting the right tools can make all the difference. Consider how a modern CAD system like Onshape could transform your machine design process and help you stay ahead in today's competitive manufacturing landscape.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Consumer Products

BOA Technology: Redefining Outdoor Fit Equipment with Cloud-Native Onshape

11.03.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more