Although reducing their carbon footprint and being a good global citizen is a primary motivation for corporations to change over to all-electric vehicles, there’s actually a more compelling business reason. Electric commercial and industrial vehicles surprisingly have a lower total cost of ownership (TCO).

“For our electric drivetrains, we often see energy efficiency above 80 percent. Typically, gasoline engines or diesel engines may be in the 20-percent range, but that’s only half the story,” says Azizi Tucker, co-founder and CTO of XING Mobility. “The real difference comes when we look at idle times. Many commercial vehicles can be idling up to 70 percent of the engine’s running time, just burning fuel while they wait. When electric vehicles are idle, power consumption goes down to virtually zero.”

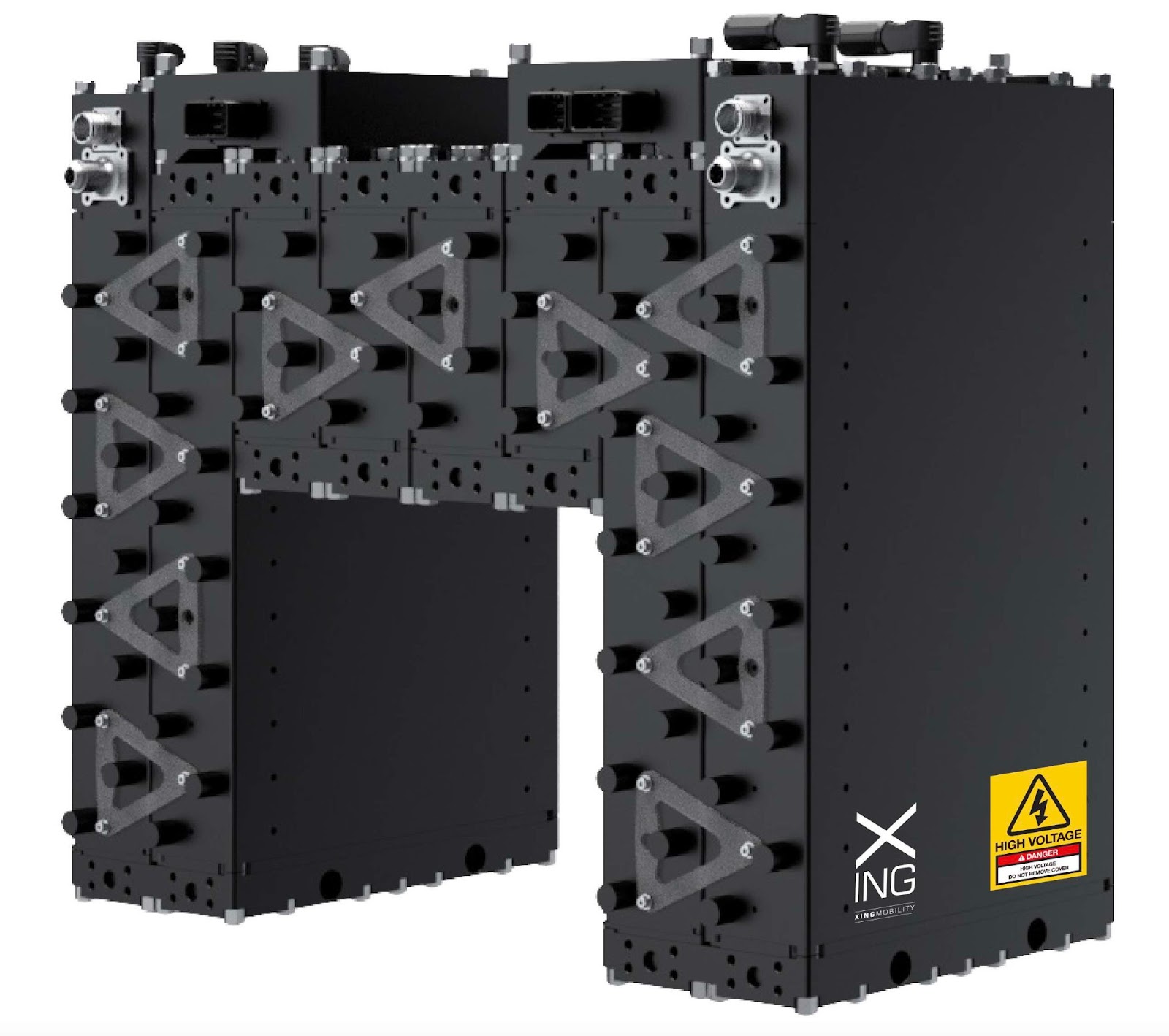

Based in Taipei, Taiwan, XING Mobility designs and manufactures modular electric battery systems and powertrains for commercial and industrial vehicles. Focusing on the mining, construction and agriculture industries, the company’s mission is “empowering every and any industrial vehicle to go electric.”

Collaborating closely with truck and construction equipment manufacturers, XING integrates customized electric battery systems to fit the existing vehicle chassis. In many cases, such as in the construction industry, it isn’t practical to design new vehicles from scratch because there may be 20 or 30 different pieces of equipment with relatively low volume on each vehicle.

Based in Taiwan, XING Mobility is a global leader in electric batteries and powertrains for the mining, agriculture and construction industries.

“XING’s modular battery system is unique in that we brought automotive quality and technology to the commercial industry – and then we packaged it with two very unique features. We use a battery module that's about half the size of a shoebox, and they stack up like Legos. We can interconnect the modules to build a battery in a variety of different sizes and shapes, and also voltages and capacities,” Tucker says.

“In addition, we're one of the only companies in this market offering immersion cooling where we're pumping liquid through the battery to eliminate hotspots. It means we control the temperature of the battery and can guarantee a very long cycle life and provide an increased level of safety,” he adds.

XING Mobility recently announced a partnership with Castrol for advancing its immersion-cooling battery technology.

Onshape’s FeatureScript Helps Reduce Hour-Long Design Tasks to Minutes

To design its unique modular electric battery and drivetrain systems, XING Mobility chose PTC’s Onshape, a cloud SaaS product development platform that enables the creation of custom industry-specific CAD features.

The modular block-building nature of XING battery systems means that vehicle manufacturers are no longer confined to a battery design shaped like a rectangle. XING can build T-shaped battery packs or any shape (even asymmetrical ones) that fits the available space inside or even outside the vehicle. In the case of an underground mining vehicle, for example, the battery pack may need to be mounted externally. With that unprecedented flexibility, however, comes an enormous product design challenge.

“We are literally designing thousands of sizes and shapes of batteries per year. So that's obviously a huge challenge, not just from an engineering perspective, but also because of the archiving, record-keeping and documentation for all these different battery systems,” Azizi notes.

To ensure its multiple mechanical and electrical engineering teams are always working on the latest version of a battery design, XING Mobility relies on Onshape’s built-in data management that eliminates the need to use an external PDM system. Whenever one engineer makes a design change, everyone else on the team can instantly see it. A comprehensive Edit History tracks who made which design change and when, enabling the team to return to any prior stage of development if needed.

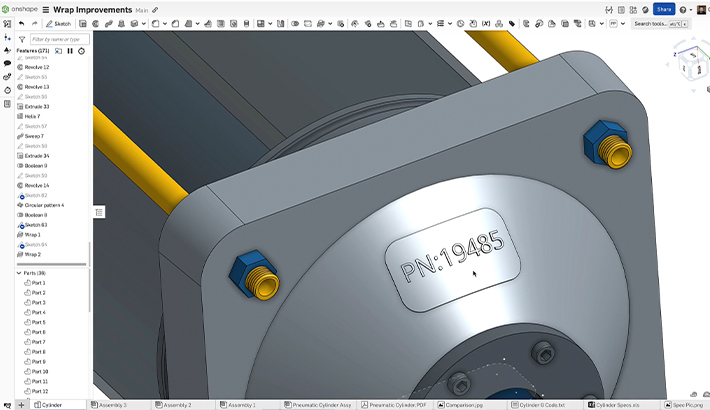

Creating unorthodox battery pack shapes from scratch is a time-consuming process, so XING engineers created their own custom feature to automate the modular configurations. Using FeatureScript, the same open-source programming language used to build all of Onshape’s native features, they built a tool to automatically stack battery modules within a predefined volume. For battery packs ranging from 50 to more than 500 components, engineers previously had to manually stack the modules one at a time.

XING Mobility’s new custom Automatic Pack Builder is akin to watching the arcade game “Tetris.” The shape stacking is automated, allowing engineers to reallocate their time to higher-value tasks.

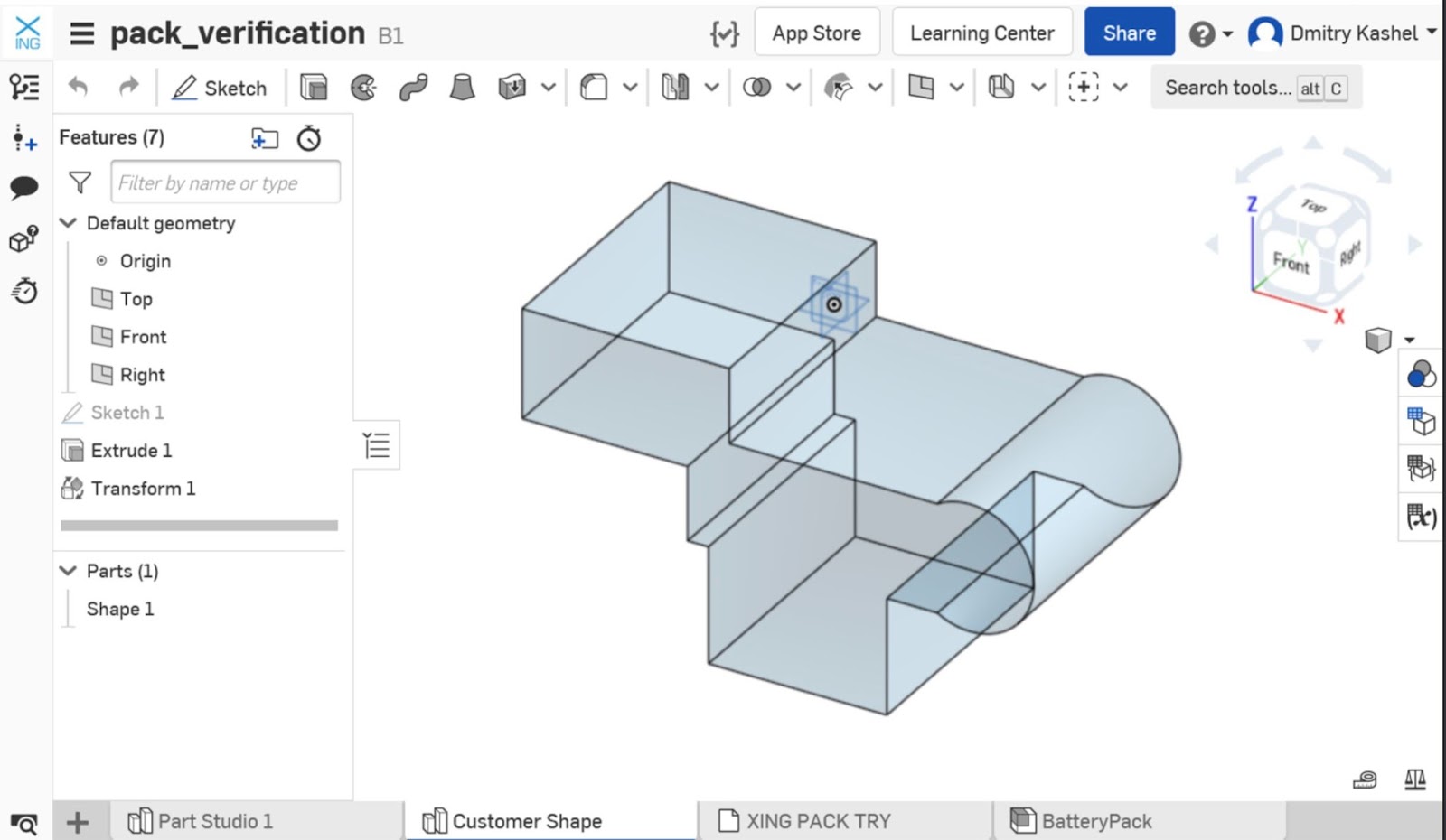

XING Mobility’s custom Onshape feature, “Automatic Pack Builder,” allows engineers to build assemblies in under a minute by establishing a predefined volume and other parameters.

“Onshape has improved our speed for creating a battery pack to less than a minute when it used to take up to an hour,” says software engineer Dmitry Kashel, who programmed the Automatic Pack Builder feature. “It’s been extremely useful for eliminating repetitive tasks.”

Noting that in the quotation phase of a project, building battery packs can often go through multiple iterations, Tucker estimates that their Onshape custom feature saved his team at least 400 engineering hours in 2020.

“In our business, adding more battery volume to a specific area is crucial,” he says. “So we’re able to add more battery volume than our competitors as a direct result of this tool.”

Future Applications of the Automatic Pack Builder

XING’s electric battery modules stack like Lego bricks and can be assembled in a variety of shapes and sizes depending on the vehicle design.

Designed for simplicity, Tucker envisions that the Automatic Pack Builder might also evolve into a productive sales tool. Sales team members without any CAD background would be able to show prospects what their custom battery packs might look like and provide alternative options and prices on the spot.

“A customer might say, ‘Hey, I have a forward base truck. Here's the chassis, here's the space where I want to put the battery.’ And our sales person could very quickly in Onshape build a simple volume to represent that space where the engine is going to be,” Tucker explains. “Then within a couple of minutes, we could say, ‘You can have 80 kilowatts of battery in this area, or if you use this other area, we could have 150 kilowatt-hours of battery.’"

“Onshape’s FeatureScript is game-changing for us. This is something I've never seen in any other CAD system,” he adds. “Our software engineers can create our own custom CAD features that are unique and suited just for our applications.”